ZED-F9P-Integration Manual

UBX-18010802 - R02

9 Product handling Page 105 of 114

Advance Information

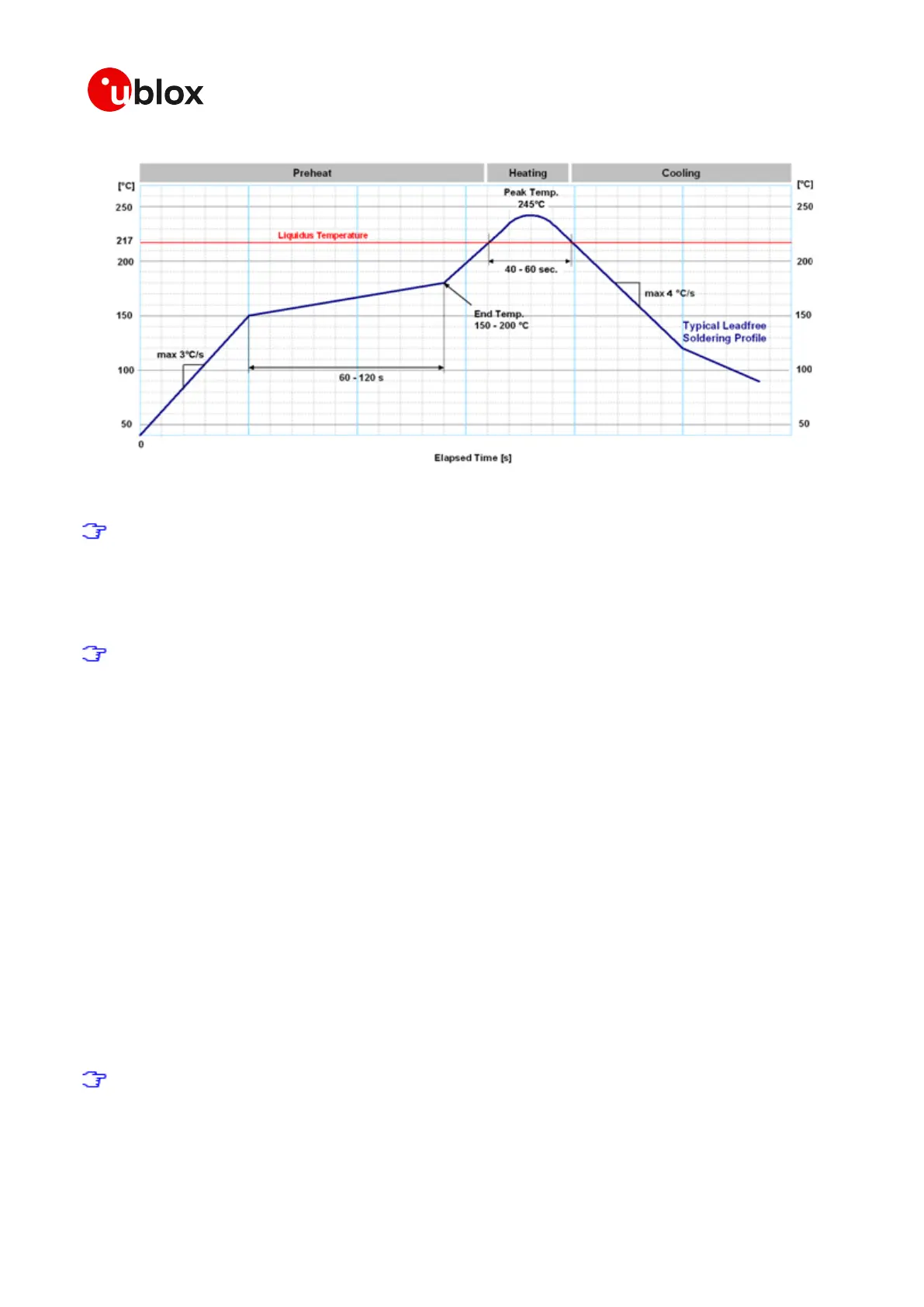

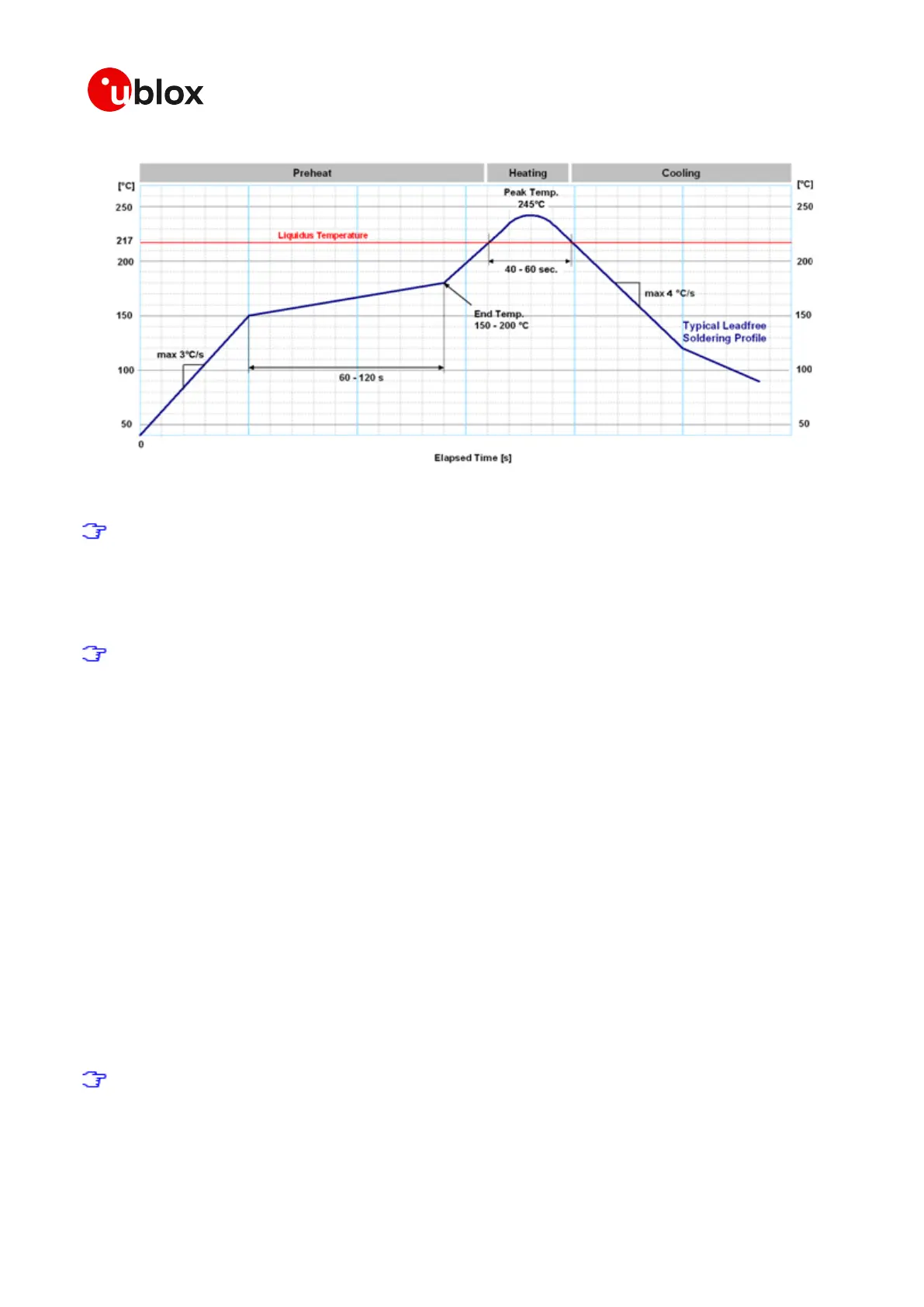

Figure 77: Soldering Profile

Modules must not be soldered with a damp heat process.

Optical inspection

After soldering the module, consider an optical inspection step.

Cleaning

No cleaning with water, solvent, ultrasonic cleaner should be carried out:

• Cleaning with water will lead to capillary effects where water is absorbed in the gap between the

baseboard and the module. The combination of residues of soldering flux and encapsulated water

leads to short circuits or resistor-like interconnections between neighboring pads.

• Cleaning with alcohol or other organic solvents can result in soldering flux residues flooding into

the two housings, areas that are not accessible for post-wash inspections. The solvent will also

damage the sticker and the ink-jet printed text.

• Ultrasonic cleaning will permanently damage the module, in particular the quartz oscillators.

The best approach is to use a “No Clean” soldering paste and eliminate the cleaning step after the

soldering.

Repeated reflow soldering

Only single reflow soldering processes are recommended for boards populated with modules.

Modules should not be submitted to two reflow cycles on a board populated with components on

both sides in order to avoid upside down orientation during the second reflow cycle. In this case, the

module should always be placed on that side of the board, which is submitted into the last reflow

cycle. The reason for this (besides others) is the risk of the module falling off due to the significantly

higher weight in relation to other components.

Two reflow cycles can be considered by excluding the above described upside down scenario and

taking into account the rework conditions described in this section.

Repeated reflow soldering processes and soldering the module upside down are not

recommended.

Wave soldering

Loading...

Loading...