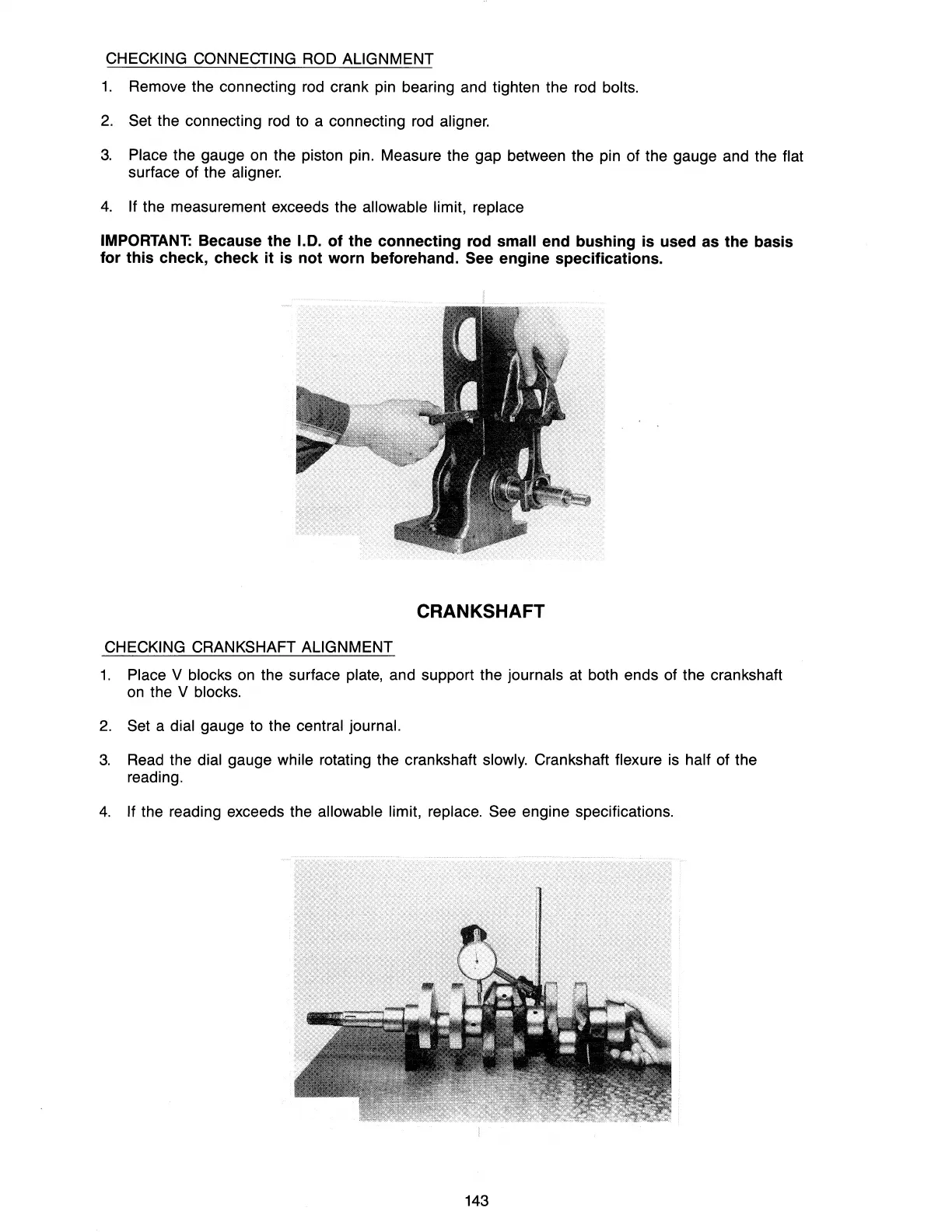

CHECKING CONNECTING

ROD

ALIGNMENT

1.

Remove the connecting

rod

crank pin bearing and tighten the

rod

bolts.

2.

Set the connecting

rod

to a connecting

rod

aligner.

3.

Place the gauge

on

the piston pin. Measure the gap between the pin of the gauge and the flat

surface of the aligner.

4.

If the measurement exceeds the allowable limit, replace

IMPORTANT: Because

the

1.0.

of

the

connecting

rod small end

bushing

is

used as the basis

for

this

check,

check

it

is

not

worn beforehand. See engine specifications.

CRANKSHAFT

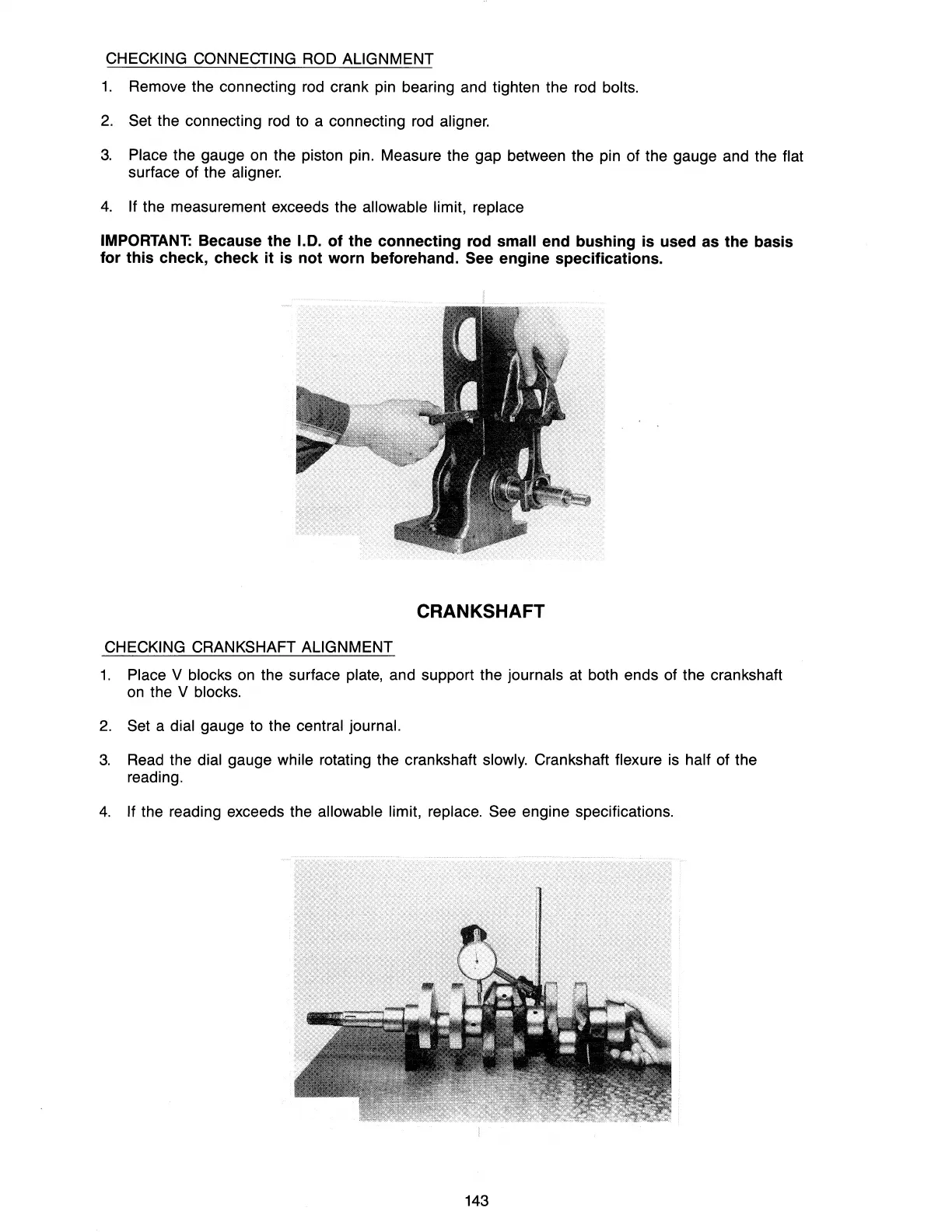

CHECKING CRANKSHAFT ALIGNMENT

1.

Place V blocks

on

the surface plate, and support the journals at both ends of the crankshaft

on

the V blocks.

2.

Set a dial gauge to the central journal.

3.

Read

the dial gauge while rotating the crankshaft slowly. Crankshaft flexure

is

half of the

reading.

4.

If the reading exceeds the allowable limit, replace. See engine specifications.

143

Loading...

Loading...