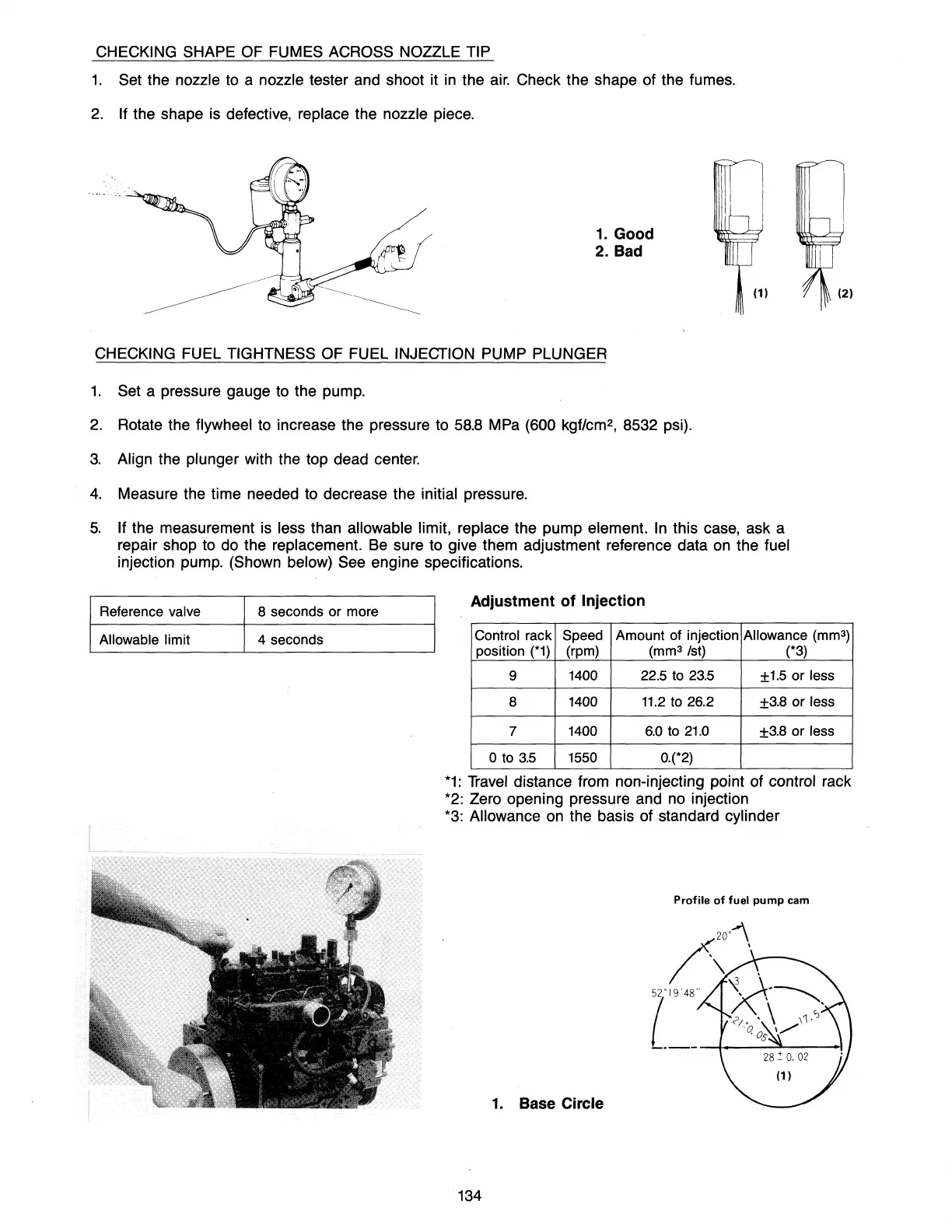

CHECKING SHAPE

OF

FUMES ACROSS NOZZLE TIP

1.

Set the nozzle

to

a nozzle tester

and

shoot it

in

the

air.

Check the shape of the fumes.

2.

If the shape

is

defective, replace the nozzle piece.

1.

Good

2.

Bad

CHECKING FUEL TIGHTNESS OF FUEL INJECfION PUMP PLUNGER

1.

Set a pressure gauge

to

the pump.

2.

Rotate the flywheel

to

increase the pressure

to

58.8

MPa

(600 kgf/cm

2

,

8532 psi).

3.

Align the plunger with the top dead

center.

4.

Measure the time needed

to

decrease the initial pressure.

5.

If the measurement

is

less than allowable limit, replace the pump element.

In

this

case,

ask a

repair shop

to

do the replacement.

Be

sure

to

give them adjustment reference data

on

the fuel

injection pump. (Shown below)

See engine specifications.

Reference valve 8 seconds or more

Allowable limit

4 seconds

Adjustment of Injection

Control rack Speed Amount of injection

Allowance

(mm3)

position

(*1)

(rpm)

(mm3/st)

(*3)

9 1400

22.5 to 23.5

±1.5

or less

8 1400

11.2 to 26.2

±3.8

or less

7

1400 6.0 to 21.0 ±3.8 or less

o to 3.5 1550 0.(*2)

*1:

Travel

distance from non-injecting

pOint

of control rack

*2:

Zero opening pressure

and

no

injection

*3:

Allowance

on

the basis of standard cylinder

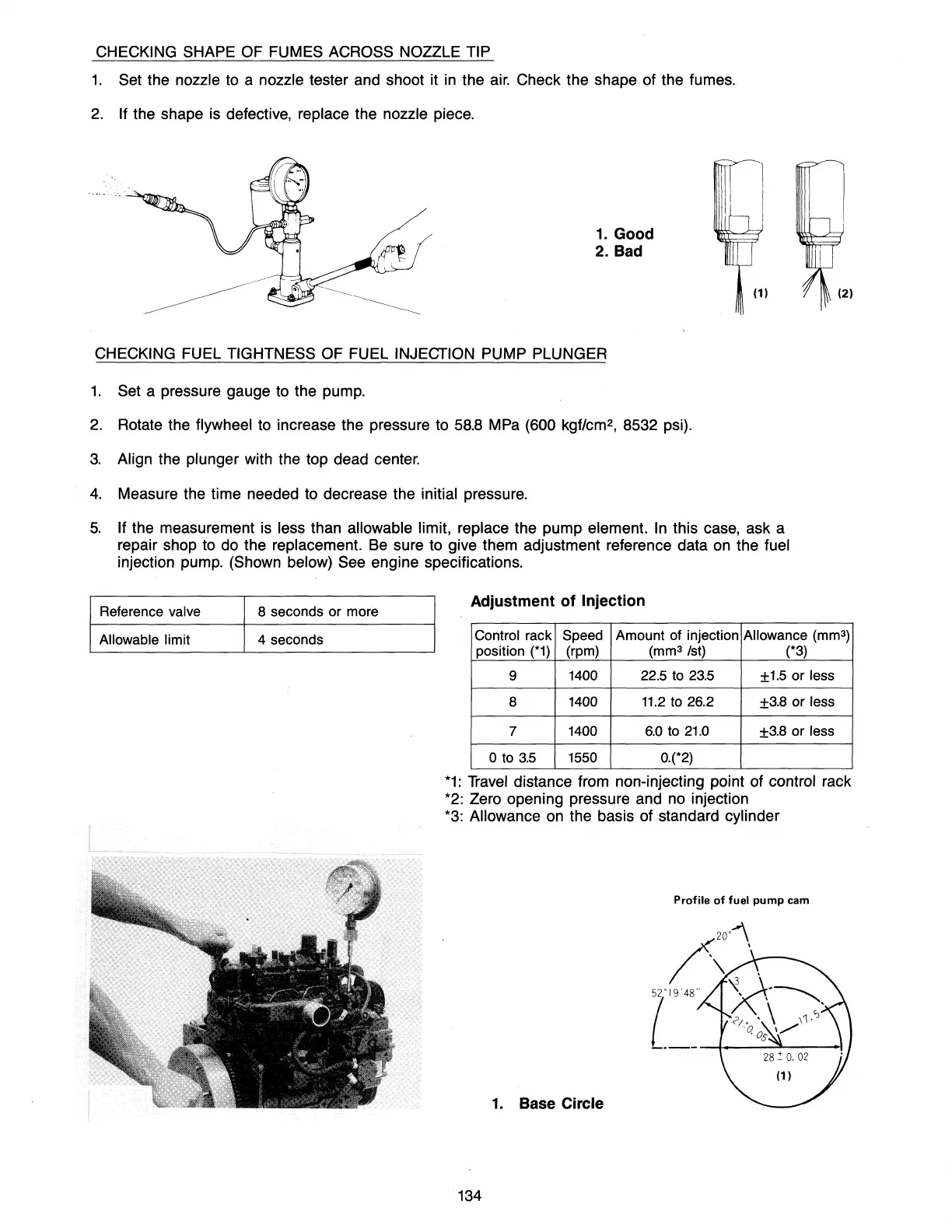

Profile

of

fuel

pump

cam

1.

Base Circle

134

Loading...

Loading...