PISTON

AND

PISTON

RINGS

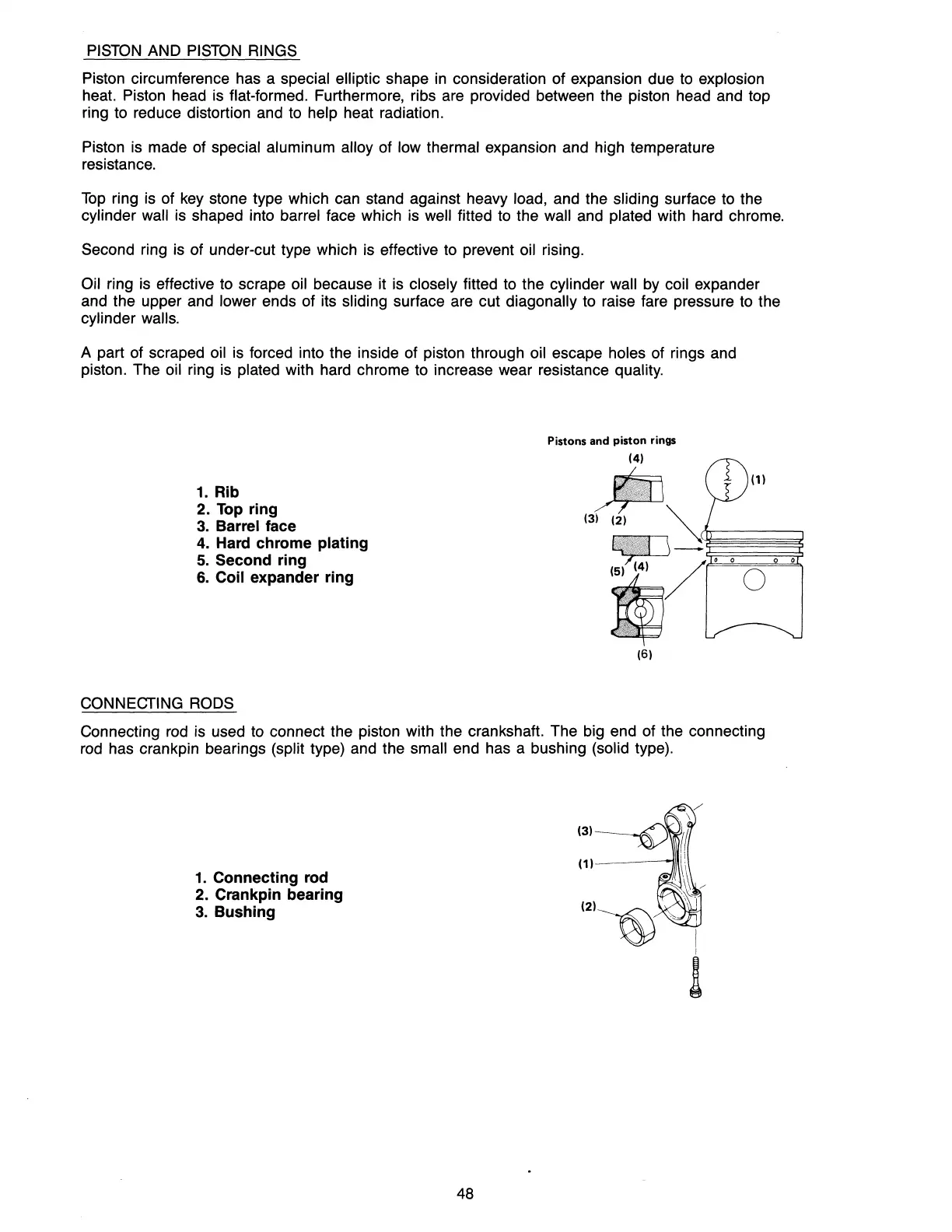

Piston circumference

has

a special elliptic shape

in

consideration of expansion due

to

explosion

heat. Piston head

is

flat-formed. Furthermore, ribs

are

provided between the piston head and top

ring

to

reduce distortion and

to

help heat radiation.

Piston

is

made of special aluminum alloy of low thermal expansion and high temperature

resistance.

Top

ring

is

of

key

stone type which can stand against heavy load, and the sliding surface

to

the

cylinder wall is shaped into barrel face which

is

well fitted

to

the wall and plated with hard chrome.

Second ring

is

of under-cut type which

is

effective

to

prevent oil rising.

Oil ring

is

effective

to

scrape oil because it is closely fitted

to

the cylinder wall

by

coil expander

and the upper and

lower ends of its sliding surface are cut diagonally

to

raise fare pressure

to

the

cylinder walls.

A part of scraped oil

is

forced into the inside of piston through oil escape holes of rings

and

piston. The oil ring

is

plated with hard chrome

to

increase wear resistance quality.

Pistons

and

piston

rings

(4)

(1)

1.

Rib

(2)

~

~-~~

15,

1

•

,

/~o

•

2.

Top ring

3.

Barrel face

4.

Hard chrome plating

5.

Second ring

6.

Coil expander ring

(6)

CONNECfING

RODS

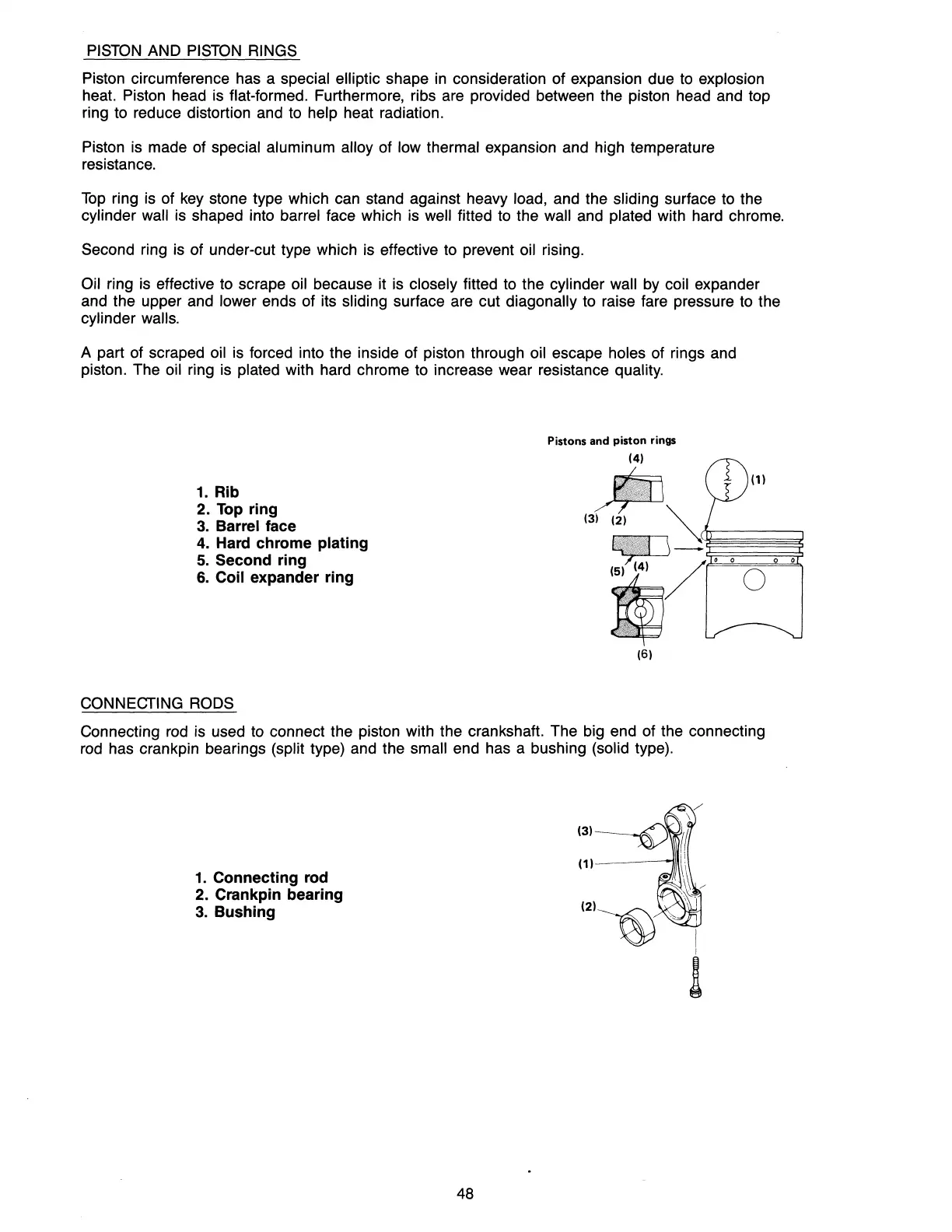

Connecting

rod

is

used

to

connect the piston with the crankshaft. The big end of the connecting

rod

has crankpin bearings (split type) and the small end has a bushing (solid type).

(3)-_~

(1)-----1/1

1.

Connecting rod

2.

Crankpin bearing

3.

Bushing

I

!

48

Loading...

Loading...