REMOVING MAIN BEARING

CASE

1.

Remove the two mounting bolts for main bearing case assembly

2.

Detach the main bearing

case,

being careful with the side and crankshaft bearings.

3.

Detach the other bearing cases 2

and

3

in

the same method.

Be

careful not

to

mix them

up.

NOTE

FOR

REASSEMBLIING: Clean the oil holes

in

the main bearing

case.

Install the main

bearing case with their side marks toward the

flywheel.

Be

sure

to

install main bearing 1 with its

oil grove facing outward. Tighten the bearing case bolts 1

to

2

to

24

Nm

(2.0

to

2.4

kgfOm,

15

to

17

ft-Ibs).

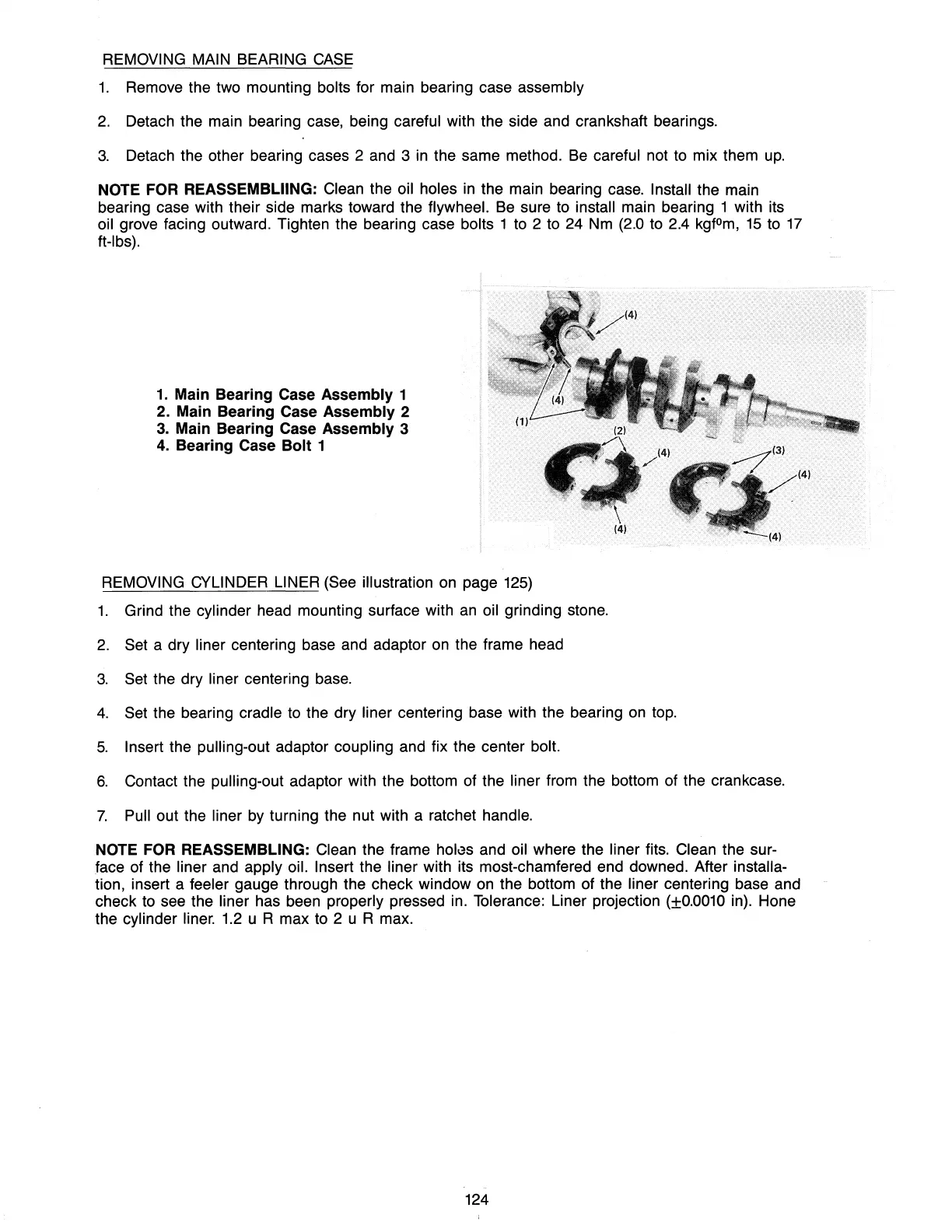

1.

Main Bearing Case Assembly 1

2. Main Bearing Case

Assembly 2

3.

Main Bearing Case Assembly 3

4.

Bearing Case Bolt 1

REMOVING CYLINDER LINER

(See

illustration

on

page

125)

1.

Grind the cylinder head mounting surface with

an

oil grinding

stone.

2.

Set a dry liner centering base and adaptor

on

the frame head

3.

Set the dry liner centering

base.

4.

Set the bearing cradle

to

the dry liner centering base with the bearing

on

top.

5.

Insert the pulling-out adaptor coupling and fix the center bolt.

6.

Contact the pUlling-out adaptor with the bottom of the liner from the bottom of the crankcase.

7.

Pull out the liner

by

turning the nut with a ratchet handle.

NOTE

FOR

REASSEMBLING: Clean the frame

holl3s

and oil where the liner fits. Clean the sur-

face of the liner

and

apply oil. Insert the liner with its most-chamfered end downed. After installa-

tion, insert a feeler gauge through the check window

on

the bottom of the liner centering base and

check

to

see

the liner has been properly pressed

in.

Tolerance: Liner projection

(±0.001O

in).

Hone

the

cylinder

liner.

1.2

u R max

to

2 u R max.

124

Loading...

Loading...