ALTERNATOR REPAIR PROCEDURE

General

The following instructions are presented as a general overall procedure for complete disassembly

of an alternator. However, it should be pOinted out that following the complete procedure whenever

a repair is necessary

will seldom, if ever, be required. In cases where the causes of the

malfunction are known, it is only necessary to follow that portion of the procedure directly related

to resolving the problem. Similarly, when the reasons for the malfunction are uncertain, it will be

necessary to

follow the procedure

in

greater depth in order to isolate and correct the problem.

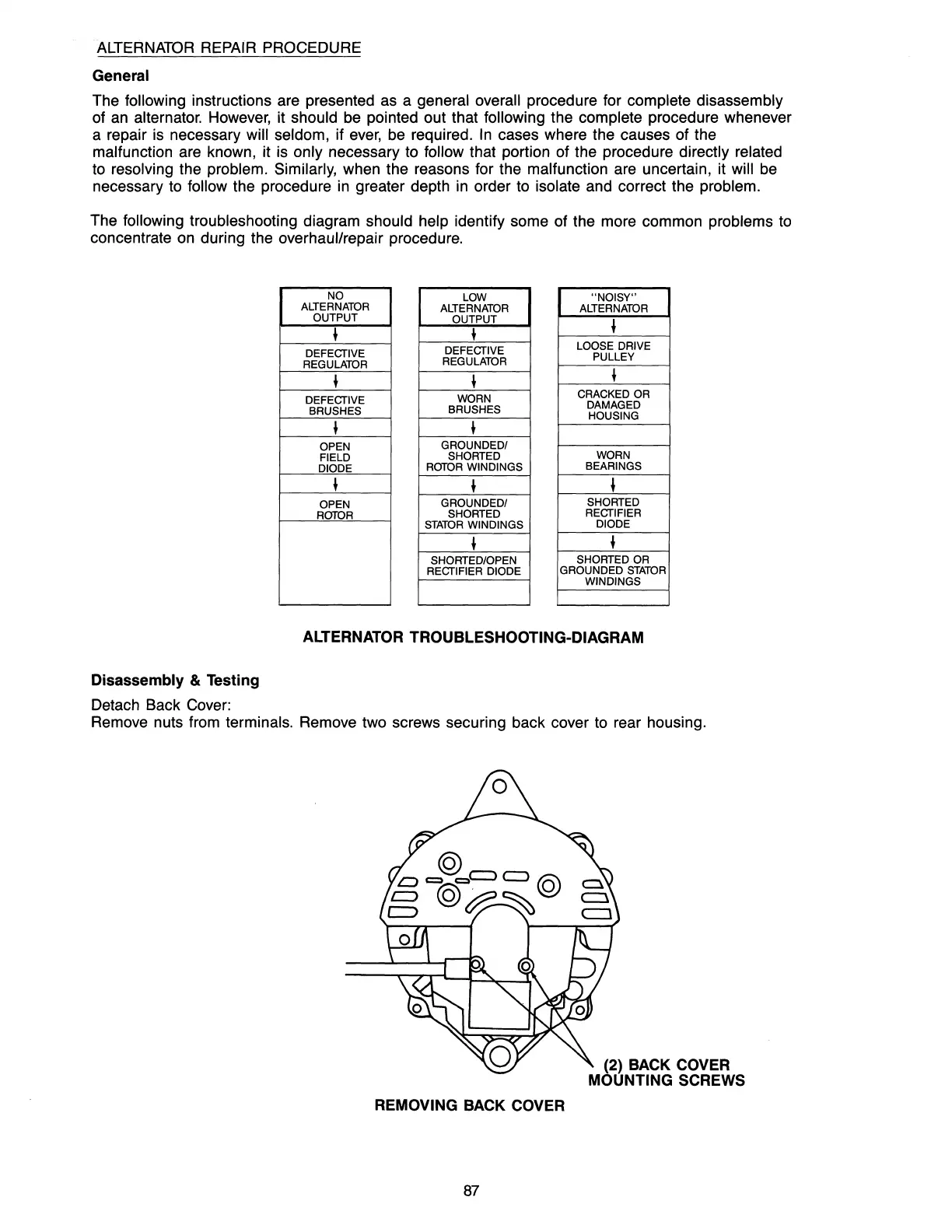

The following troubleshooting diagram should help identify some of the more common problems to

concentrate on during the overhaul/repair procedure.

Disassembly

& Testing

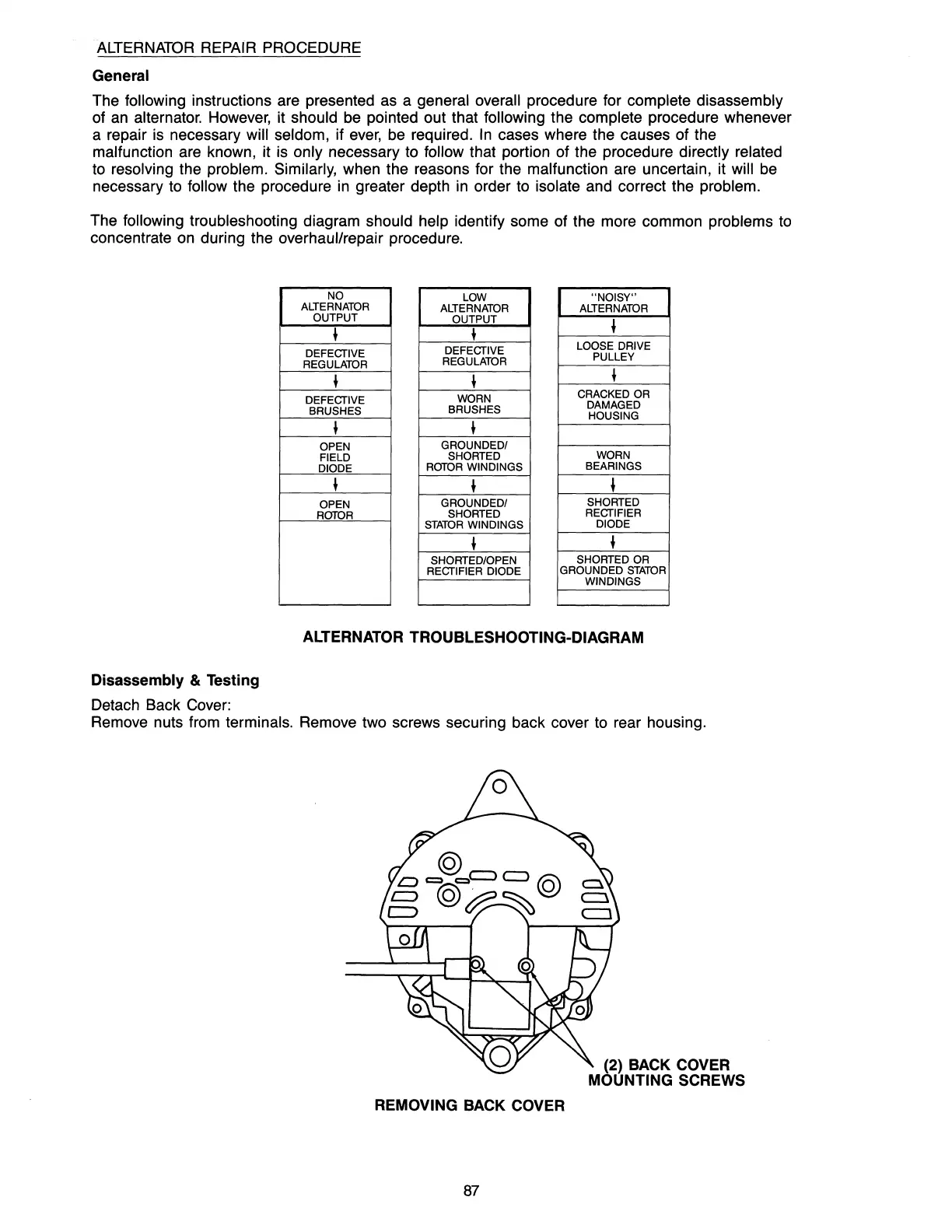

Detach Back Cover:

NO

LOW

"NOISY"

ALTERNATOR

ALTERNATOR ALTERNATOR

OUTPUT

•

OUTPUT

+

,

DEFECTIVE

REGULATOR

•

DEFECTIVE

REGULATOR

•

LOOSE DRIVE

PULLEY

•

DEFECTIVE

BRUSHES

WORN

BRUSHES

CRACKED

OR

DAMAGED

HOUSING

•

•

OPEN

FIELD

GROUNDEDI

SHORTED

WORN

DIODE

RareR

WINDINGS

BEARINGS

•

•

,

OPEN

RareR

GROUNDEDI

SHORTED

STATOR

WINDINGS

SHORTED

RECTIFIER

DIODE

•

•

SHORTED/OPEN

SHORTED

OR

RECTIFIER DIODE

GROUNDED

STATOR

WINDINGS

ALTERNATOR TROUBLESHOOTING-DIAGRAM

Remove nuts from terminals. Remove two screws securing back cover to rear housing.

REMOVING BACK COVER

87

(2) BACK COVER

MOUNTING SCREWS

Loading...

Loading...