1006

Model Code Page

66. Air suspension of front axle

1. 8. 2000

660 46200--8950

1. 11. 1998

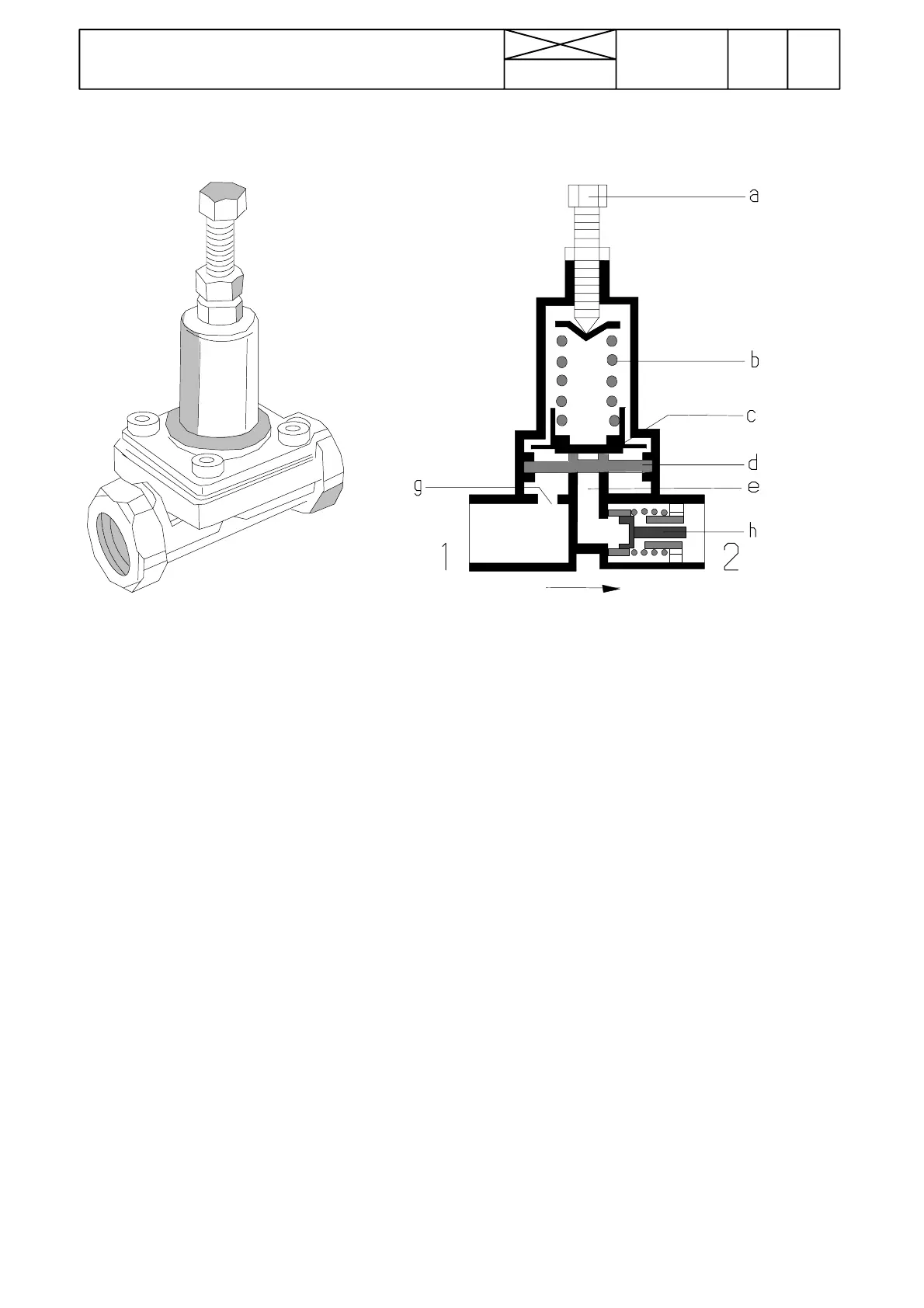

2. Overflow valve

(only on tractors equipped with pressure air brakes)

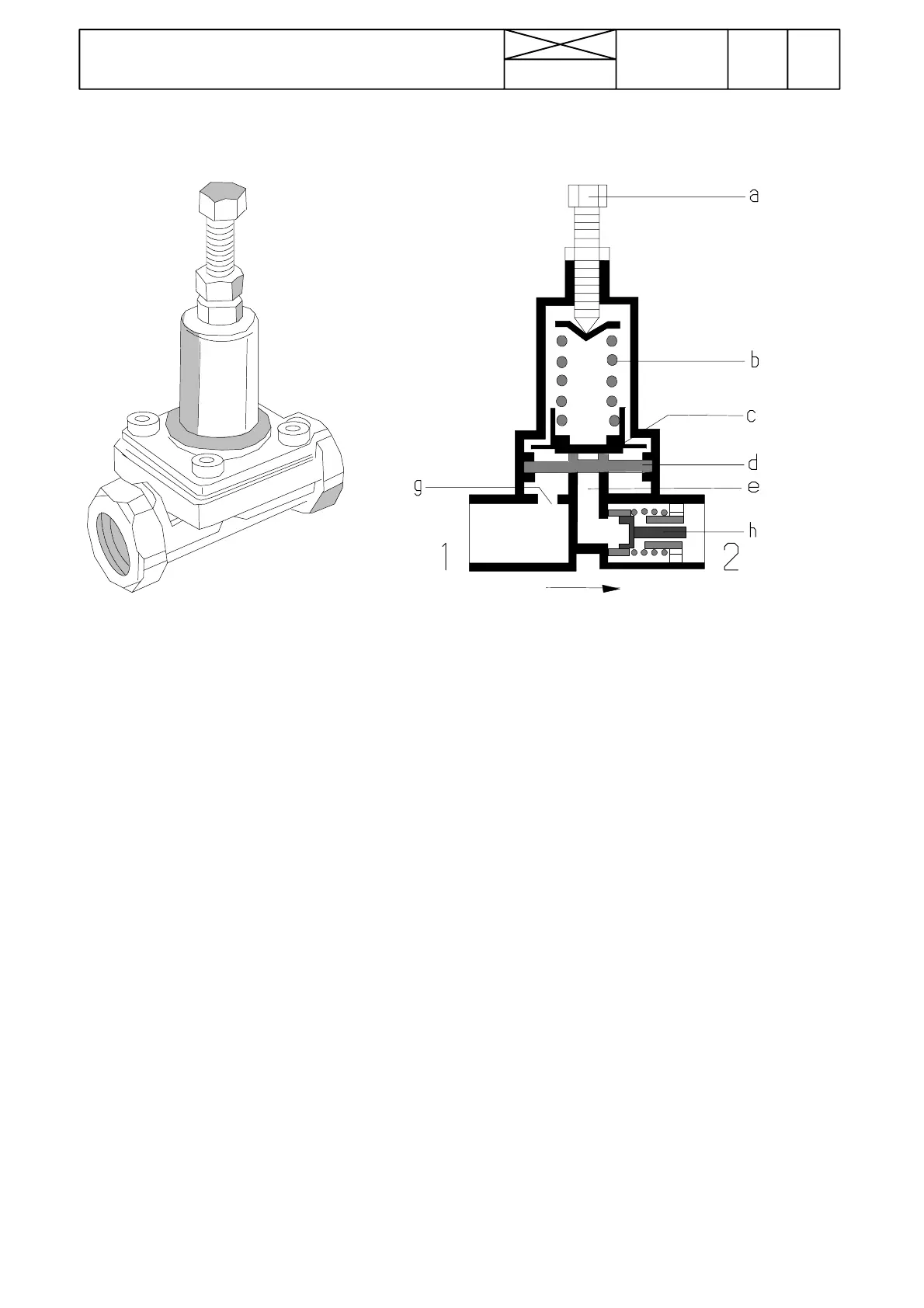

A. Function

This valve ensures that the pressure air flow into the sus-

pension occurs just when the correct pressure affects the

air brake system (although the suspension air bellows are

leaking). Non---return valve (h) prevents return of the air

form port 2 (suspension) to port 1 (reservoir). If the pressure

drops in port 1, the pressure in the second side 2 remains

the same.

Compressed air flows in the direction of the arrow through

valve and through port (g) to the underside of membrane

(d). Spring (b) presses the membrane against the seat.

When enough high pressure has reached (6,2---6,5 bar),

springforce(b)isovercomesothatthemembrane(d)rises

up from its seat and passage (e) opens . Air flows thr ough

the no n---return valve (h) into the suspension. Return flow is

impossible since the non---return valve closes, if the pres-

sure in the suspension is higher.

B. Adjustment

The valve opening pressure can be adjusted by turning

screw (a). When turning clockwise the opening pressure

increases and vice versa.

The valve does not need any maintenance. Opening pres-

sure (1 ---> 2) factory setting is 6,2---6,5 bar (closing pres-

su r e --- 1 0 % ).

Note! In case of damage the whole valve is changed.

3. Other components

Compressor, deicer, pressure regulator, pressure reservoir

andpressuregaugearethesameasfortheairbrakesof

the trailer (option).

Concer ning these parts, see pages 510/6---7 and

511/4---7.

Note! The pressure air pipes of the suspension system

have been made of nylon pipes and quick couplings.

IMPORTANT! Although the engine is stopped, the suspen-

sion system remains under pressure. Always before main-

tenance works, make the system unpressurised e.g. by

turning the level valve linkage.

Loading...

Loading...