Potentiometer

96

Model Code Page

32. Electro---hydraulic power lift

1. 6. 1999

6000--8400 320 14

1. 9. 2002

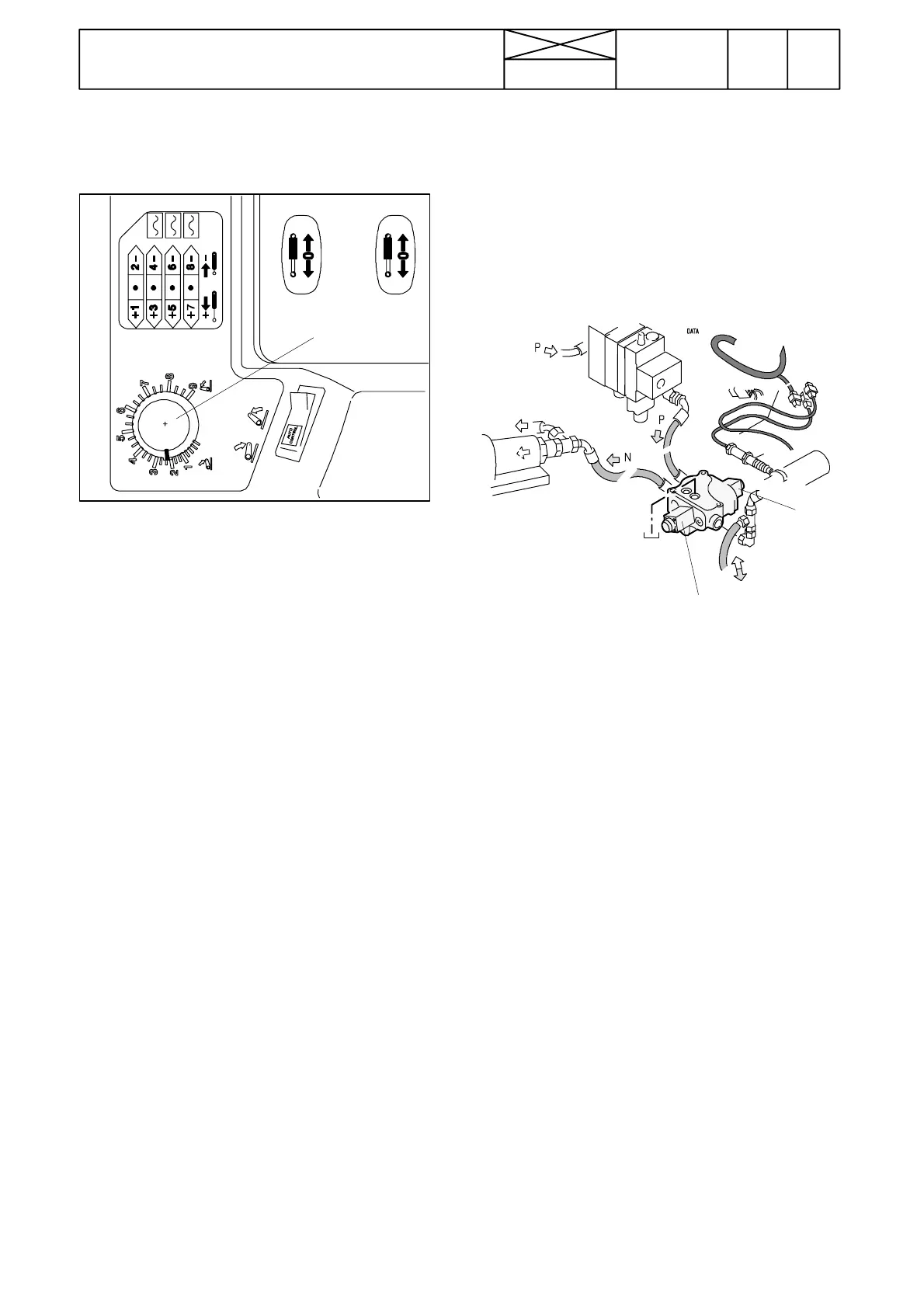

3. Checking the position control potentio-

meter

1. Stop the engine and switch off current

2. Remove the side panel of the lever console in cab and open

the position control potentiometer connector.

3. Measure resistance (between blue and black leads) when

the knob is in its both extreme positions and also in positions

4 and 7. Correct values should be:

Max. anti---clockwise 0,9

Ω (±20 %)..........

Po int4 1420

Ω (±20 %).......................

Point 7 3,3 k

Ω (±20 %)......................

Max. clockwise 4,7 k

Ω (±20 %)...............

4. Then rotate the position control knob slowly from one ex-

treme position to the other and make sure that the resistance

value changes linearly without steps.

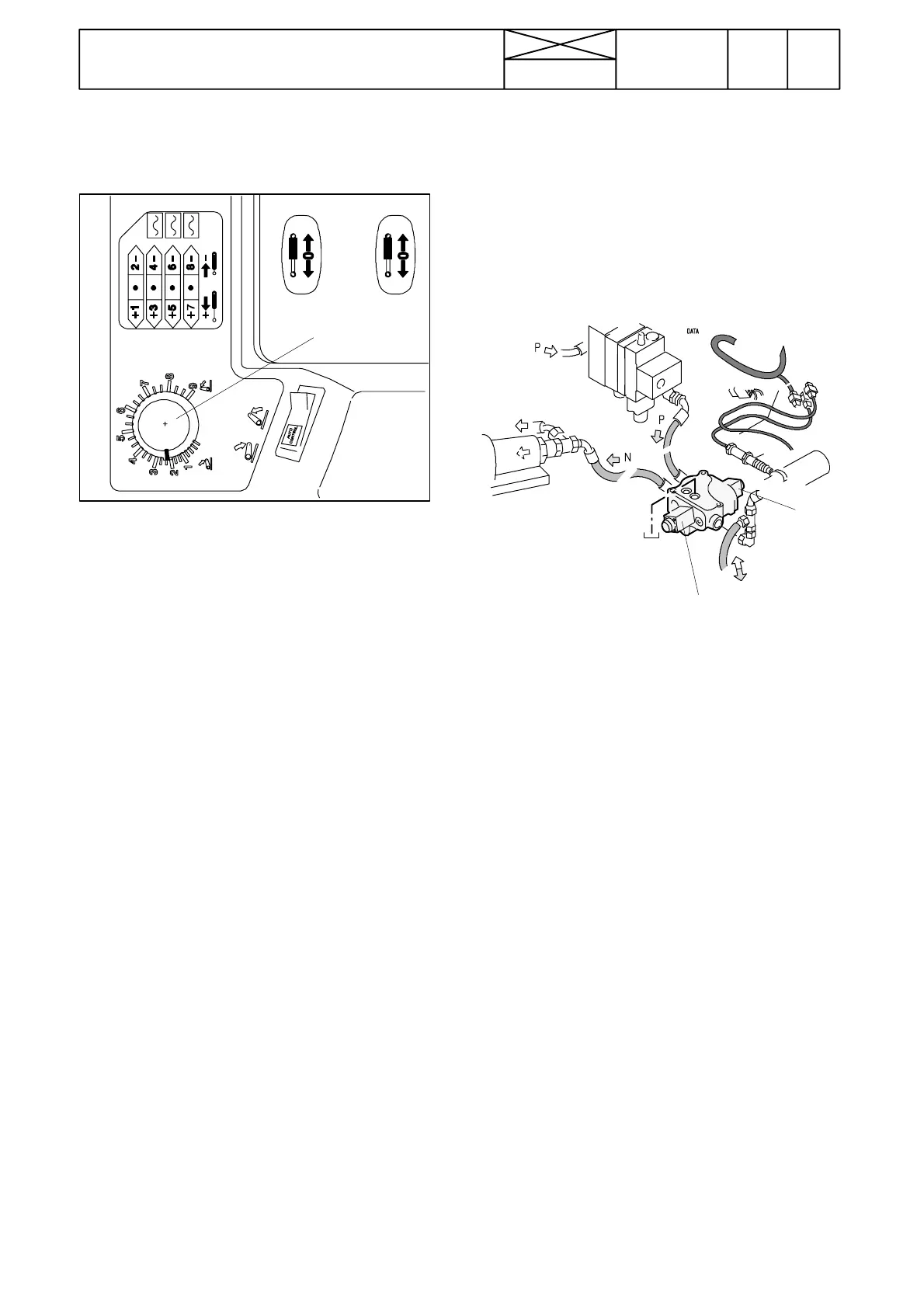

4. Checking c ontrol valve and its solenoid

valves

If the lifting or loweri ng speeds do not function correctly, it is

necessary to clear up whether the fault lies in the electric sys-

tem or in the control valve (valve spools can get trapped etc.).

Checking electric system:

A

Y1E

Y2E

Connect an ampere--- meter in series with control valve sole-

noids. Y1E lowering (inner) and Y2E lifting (outer). Use ETV

894 220 when measuring these values, see page 101/1.

Lifting approx 3,45 A.........................

Lowering (yellow buttons) approx 1,96 A........

Lowering speed positions:

1 approx 1,40 A.............................

2 approx 1,55 A.............................

3 approx 1,70 A.............................

4 approx 2,15 A.............................

5 approx 2,60 A.............................

6 approx 3,45 A.............................

Resistance of solenoid approx 1,6 Ω...........

Checking control valve:

If the measured values agree with the correct values above,

but malfunctions occur in the lowering and lifting functions,

the control valve should be removed and checked (see page

912/2).

Loading...

Loading...