77

Model Code Page

21. Engine

15. 5. 1993

6000--8750

216 3

1. 9. 1992

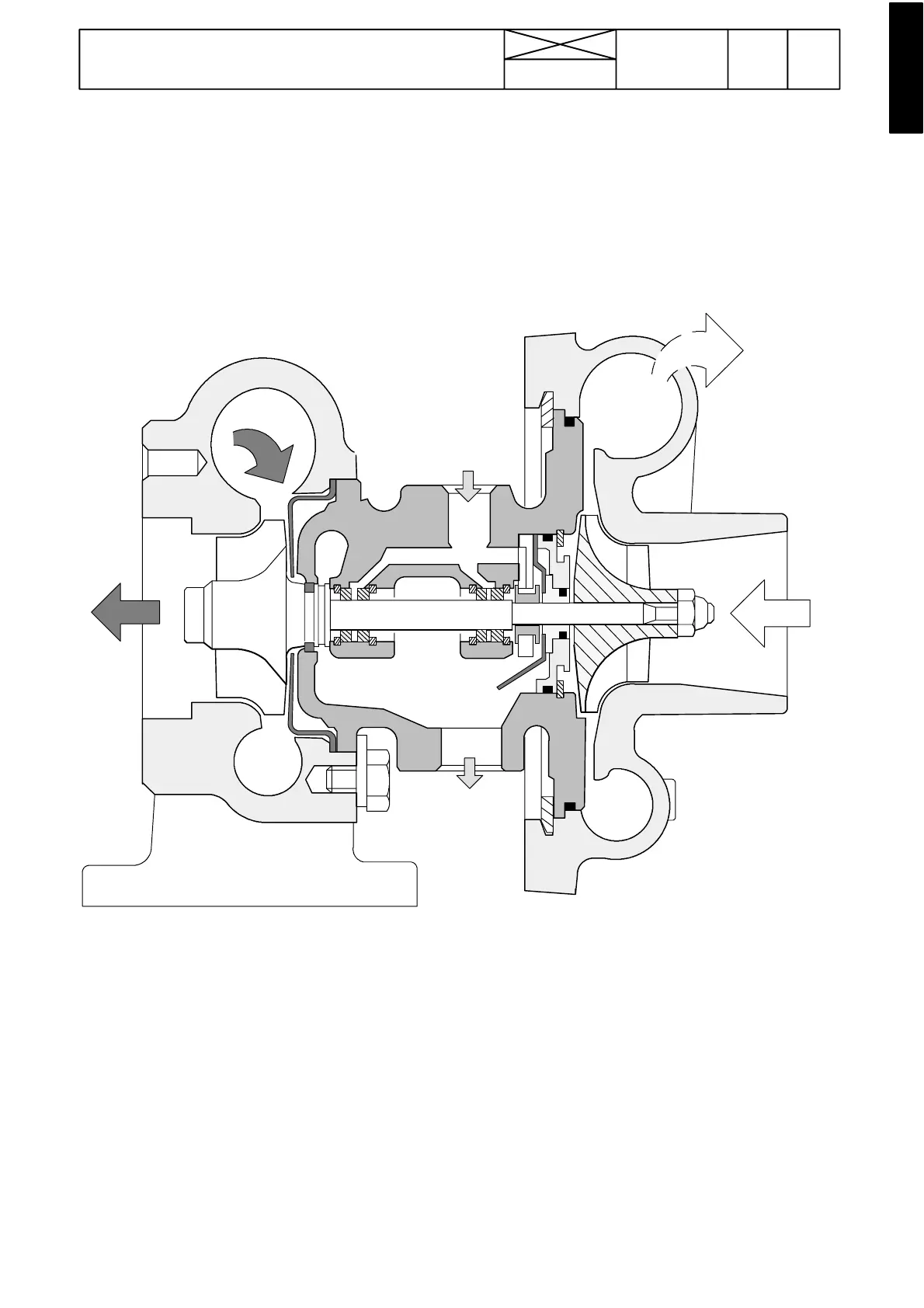

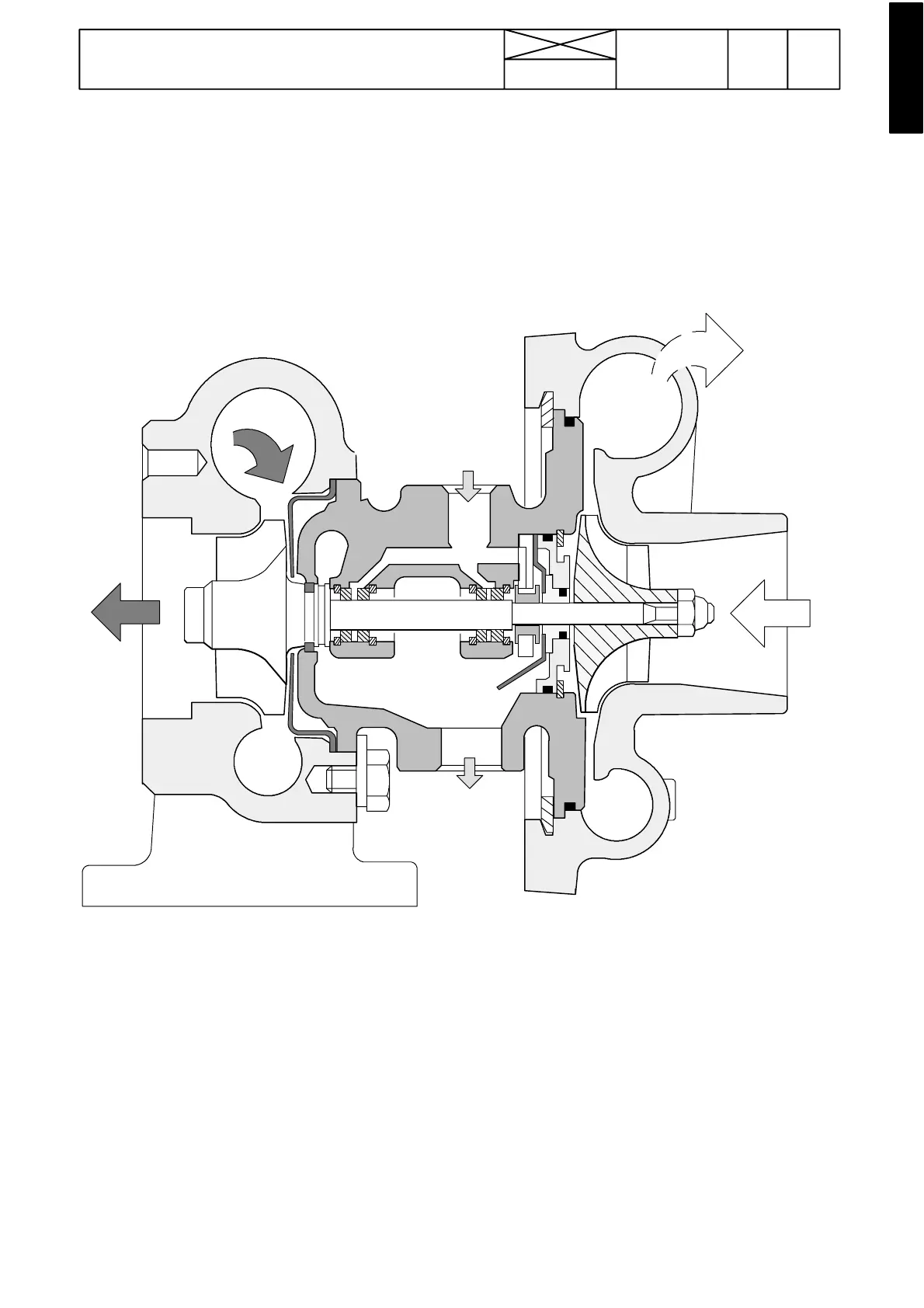

D. Reconditioning turbocharger

(Schwitzer S1A, S1B, S2B)

N.B! Thesamedegreeofcleanlinessshouldbeobserved

when removing the turbocharger as with repairing the fuel

system. Only remove the compressor and turbine covers if

the requisite special tools, e.g. for adjusting the balance, are

not available. In general, when the turbocharger is dam-

aged it is more economical to fit a factory reconditioned

turbocharger.

Dismantling turbocharger

1. Mark the compressor housing, turbine housing and the

bearing housing in relation to each other.

2. Fix the turbocharger by the outlet flange in a vice fitted with

soft jaws.

3. Remove the compressor housing circlip and remove the

housing.

4. Unscrew the turbine housing fixing screws and remove the

fixing plate. Detach the bearing housing from the turbine

housing.

5. Hold the turbine wheel at hub and unscrew the compressor

wheel nut (left---hand thread). Removethe compressorwheel.

6. Remove the turbine wheel/shaft carefully by tapping at the

shaftendwithasofthammer.Donotbendtheshaft.

7. Place the bearing housingon a tableso that the turbine side

is against the table. Remove the support flange circlip.

8. Remove the support flange and theoil deflector ring by pry-

ing with two screwdriver behind the support flange grooves.

Press the deflector ring out of the support ring.

9. Remove the oil deflector plate, thrust bearing and thrust

sleeve from the bearing ho us ing. Remove the bearing outer

circlips and remove the bearings and the inner circlips.

Loading...

Loading...