862

Model Code Page

46. Front PTO

1. 4. 1997

8450--8750 463 14

3. Front PTO 8450-- 8750,

repair instructions

A. Maintenanc e

See page 463/9.

B. Fault tracing

See page 463/10.

C. Adjusting engaging time

See page 463/10.

D. Removing front PTO unit

--- Release the clutch pressure hose on the unit front face

--- Release the oil cooler hoses (oil draining) and remove

the oil cooler

--- Unscrew the elastic joint bolts, which are fitted radially

--- Remove the top link bracket of the front lift

--- unscrew the front unit fixing bolts (4 pcs)

Note! It is possible to remove separately the PTO housing

front half while the unit is attached to the tractor, at which

time the PTO shaft, gear wheels and bearings are access-

ible. There is a paper gasket with thickness of 0,4 mm

between the housing halves.

E. Changing V---belts / elastic joint

V --- b e l t s :

--- Remove the top link bracket of the front lift.

--- Remove the oil cooler and its return hose

--- Unscrew the elastic joint bolts, which are fitted radially

--- Unscrew the PTO unit two lo wer fixing bolts and fit in

place screws with length of 100mm (M14)

--- Unscrew the two upper fixing bolts

--- Pull the unit forwards along the lower bolts

--- Pull the drive shaft front end out of its spline joint

--- Pass the V---belts onto the shaft through the hole on the

cowl

Note! Refitting is done in the reverse order. In order to

make the r efitting easier, push the drive shaft front end

into the rear end splined joint before fitting the unit

Note! In addition the viscous fan must be detached on

thecoolantpumpsideandpossibleaircompressor

V---belt should be slackened.

Elastic joint:

Before changing work, the front PTO unit must be removed.

When refitting the rubber coupling, tighten the 4 radial and

4 axial bolts to a torque of 140 Nm. Apply a little grease

onto the bolt head lower surfaces. (also see picture 16 on

page 463/4).

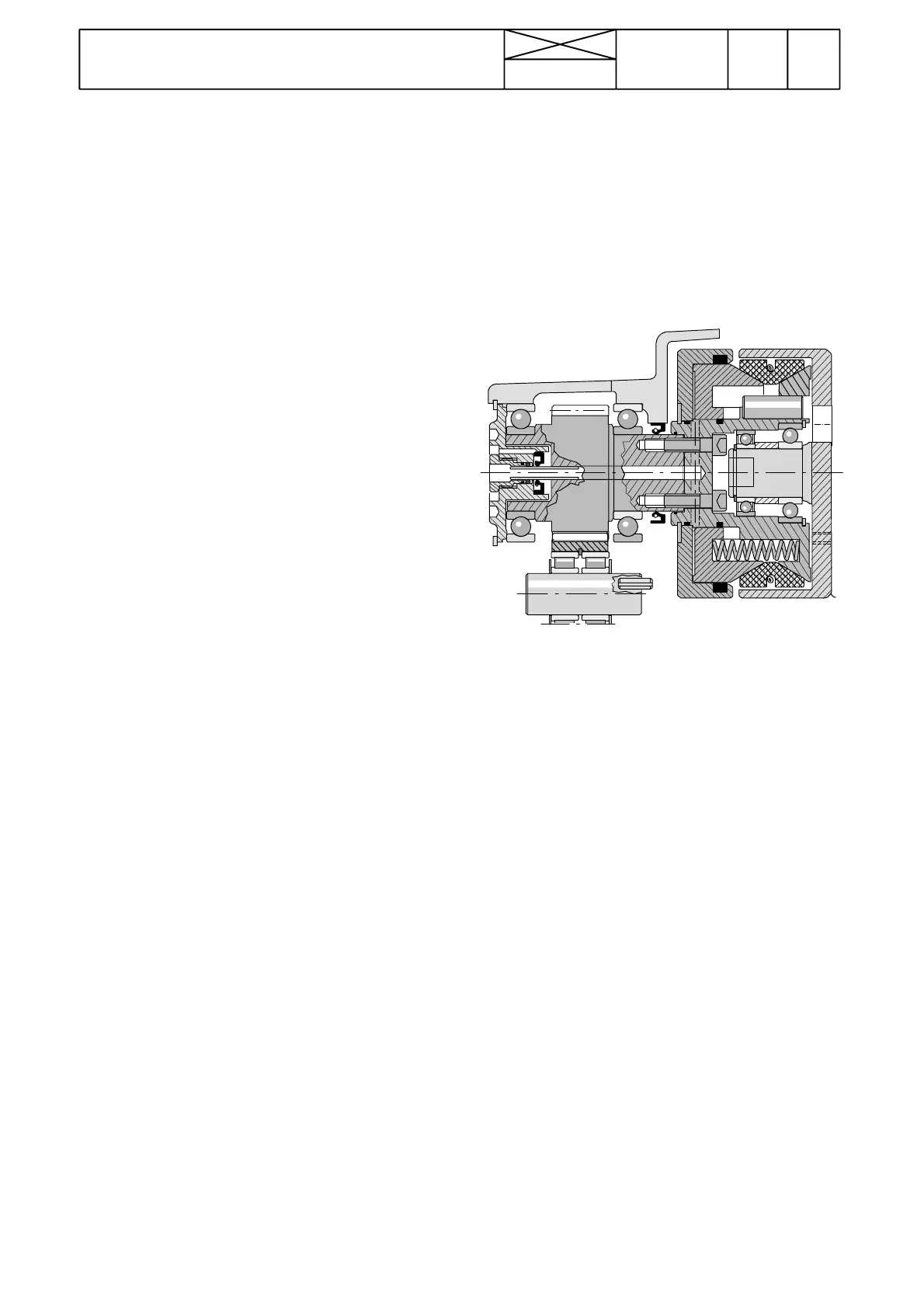

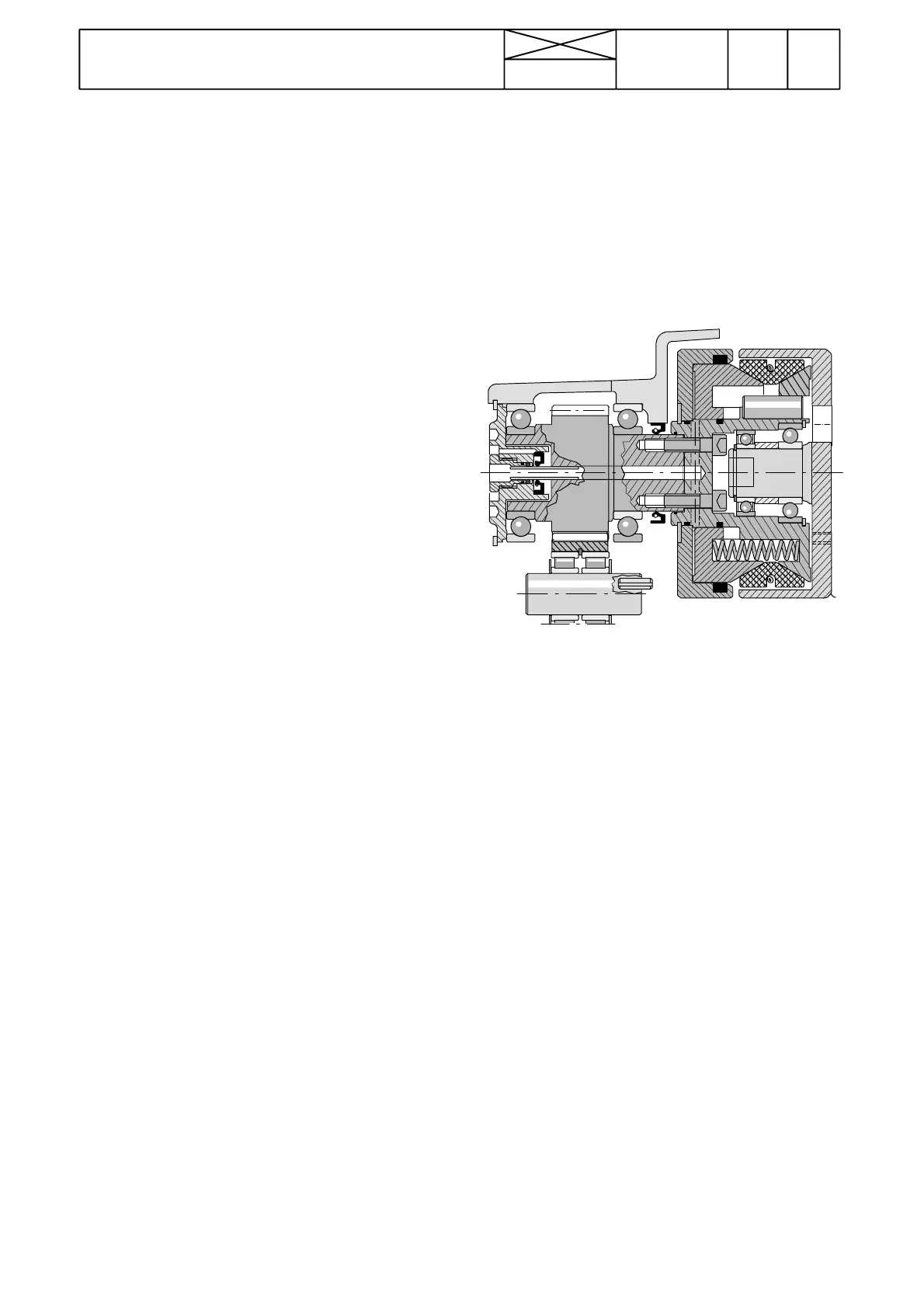

F. Cone clutc h

Before the cone clutch can be dismantled the PTO unit

must be removed.

The cone clutch is dismantled as follows:

--- r e m ov e t h e el a st i c j o in t

--- release the clutch bearing circlip through the holes in the

clutch drum end

--- pull out the drum with aid of puller screws (M10) after

which the friction pieces are accessible. The bearings

loosen when the clutch drum is pulled out.

--- If the clutch piston seals or the upper shaft oil seal have

to be changed, unscrew the clutch hub six bolts, after

which the seals can be changed.

G. Others

The PTO shaft oil seal as well as the upper shaft flange

seals can be changed without removing the front PTO or

thePTOshaft.Thepumpdrivesleeveinthefrontendof

the PTO s haft has a press---fit. In addition, locking fluid

has been used.

Loading...

Loading...