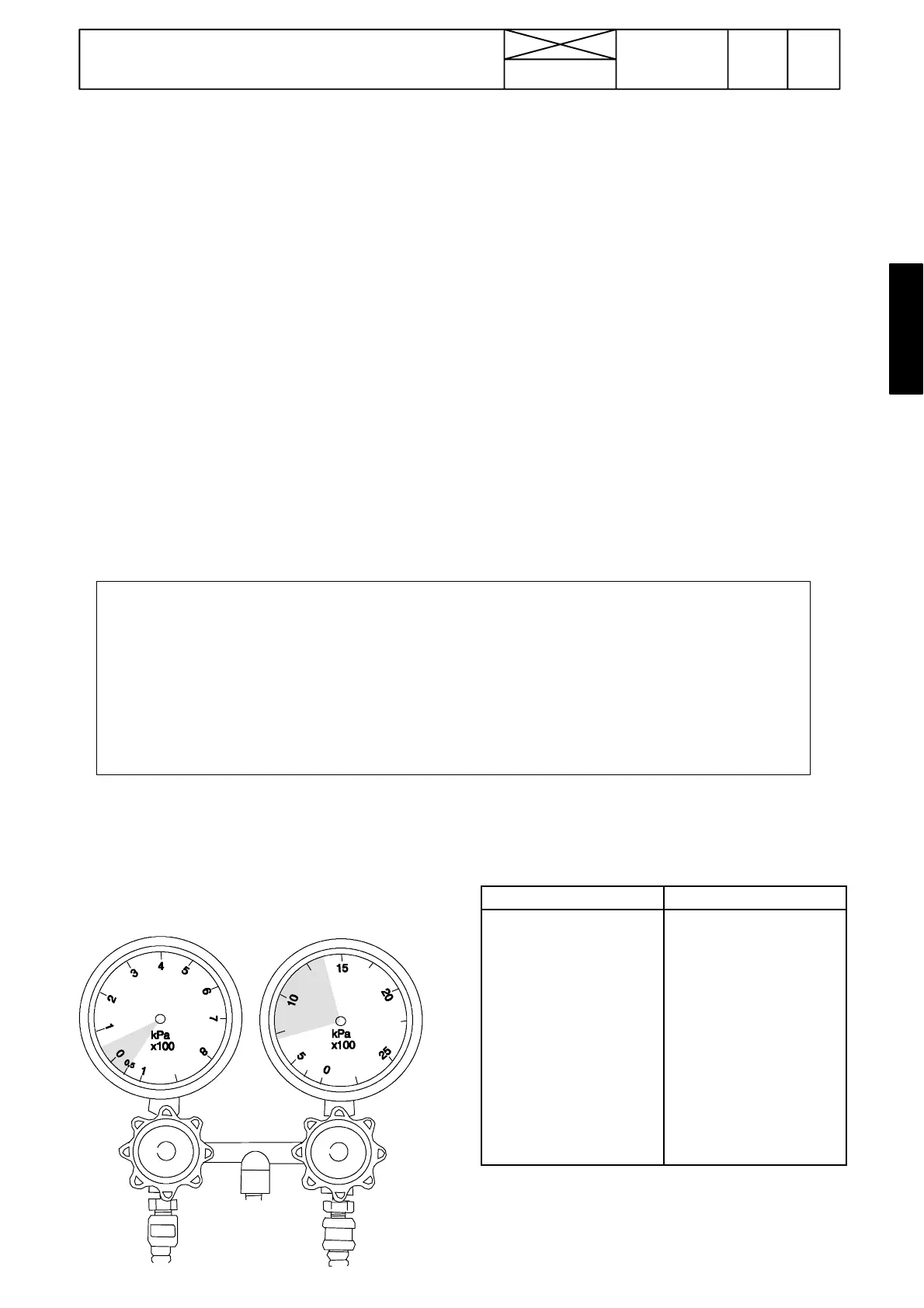

Connecting pressure

gauges:

Stoptheengine.Removetheservicevalveprotectivecaps.Connectthelowpres-

sure gauge to valve S and high pressure gauge to valve D.

Disconnecting gauges: Stop the engine. Unscrew rapidly the low pressure gauge. Run the air co nditioner

5---10 min and stop the engine. Unscrew rapidly the high pressure gauge.

Note! Refrigerant in the gauge hoses blows off. Use gloves and goggles when con-

necting and disconnecting gauges. Recap valves.

1147

Model Code Page

83. Air conditioner

1. 4. 1997

6000--8750 831 5

1. 1. 1994

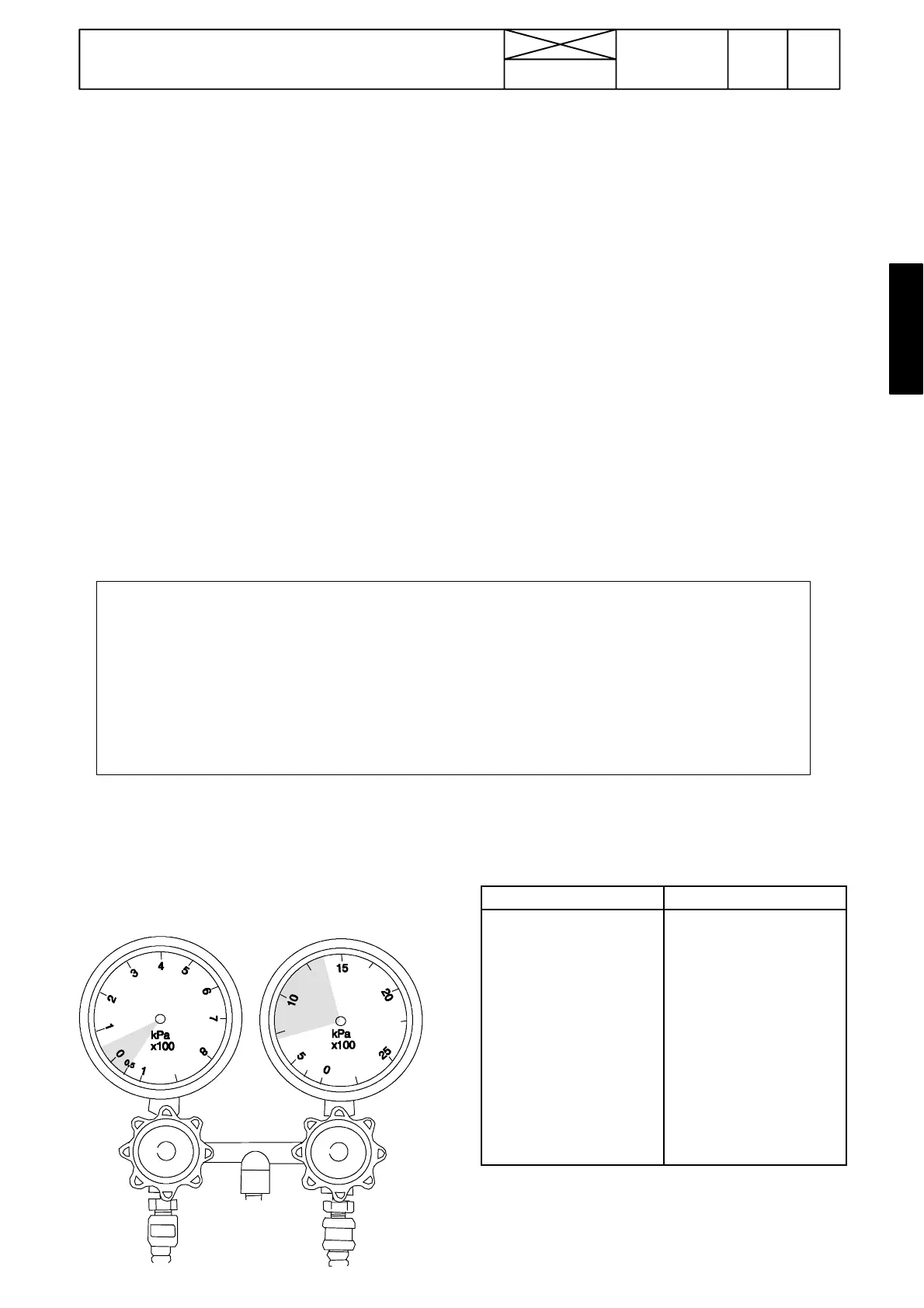

2. Trouble shooting with pres-

sure gauges

System pressures depend directly on air pressure and tem-

perature. At outdoor temperature 20˚ --- 2 5 ˚C and at engine

revs 1500 r/min the low pressure varies between 50 ---300

kPa and the high pressure between 700 ---1400 kPa.The

pressure gauges are connected to the compressor service

valves: low pressure gauge to (S) and high pressure gauge

to (D). The service valves are different on the air conditioners

which have refrigerant R134a thus preventing mischarging

with freon R12.

Fault analysis and symptoms

a) Leaks in the system will lead to inadequate cooling and low

and high gauge readings will be too low.

b) If the system is under---charged, bubbles will be perma-

nently visible in the dehydrator sight glass and both gauge

readings will be low.

c) If the evaporator is dirty or an expansion valve is blocked

or frozen up, there will be a partial vacuum on the lowpressure

side and insufficient pressure on the high pressure side.

Low pressure too low High pressure normal

DS

d) An over---charged system, an expansion valve stuck open

or a clogged condenser will cause excessive pressure on the

low pressure side.

e)Acloggedcondenserandanover---chargedsystemwill

cause excessive pressure on the high pressure side.

Overcharge

Note! The correct refrigerant filling is 1,4 kg on Valmet

6000---8750 tractors.

In a correctly charged system, R12 discharged from the com-

pressor in the form of gas looses its excess heat, resulting

from compression in the first coil of the condenser and con-

denses to a liquid in the subsequent coils. B efore flowing to

the reservoir, this liquid is held in the last condenser coil. If the

system is over---charged, the liquid level builds up in the con-

denser, leaving fewer coils available to condense the gas.

Both temperature and pressure then build up, causing hoses

to burst in some cases.

Possible fault

Remedy

1. Expansion valve faulty.

2. Moisture in system caus-

ing icing in expansion valve

3. Expansion valve is

cloggedorevaporatordirty,

if low pressure gauge

shows underpressure.

4. Drier blocked (t empera-

ture difference on different

sides of blockage causes

icing in the drier when air

conditioner is functioning).

1. Change expansion valve.

2. Empty and flush the sys-

tem. Change the drier and

theexpansionvalveif

necessary.

3. Empty system and

change the expansion

valveandalsotheevapor-

ator and drier if necessary.

4. Empty system and

change the drier.

Loading...

Loading...