1245

Model Code Page

91. Hydraulic system

1. 1. 1995

6000--8750 911 5

2. Pump and pipes, fault tracing

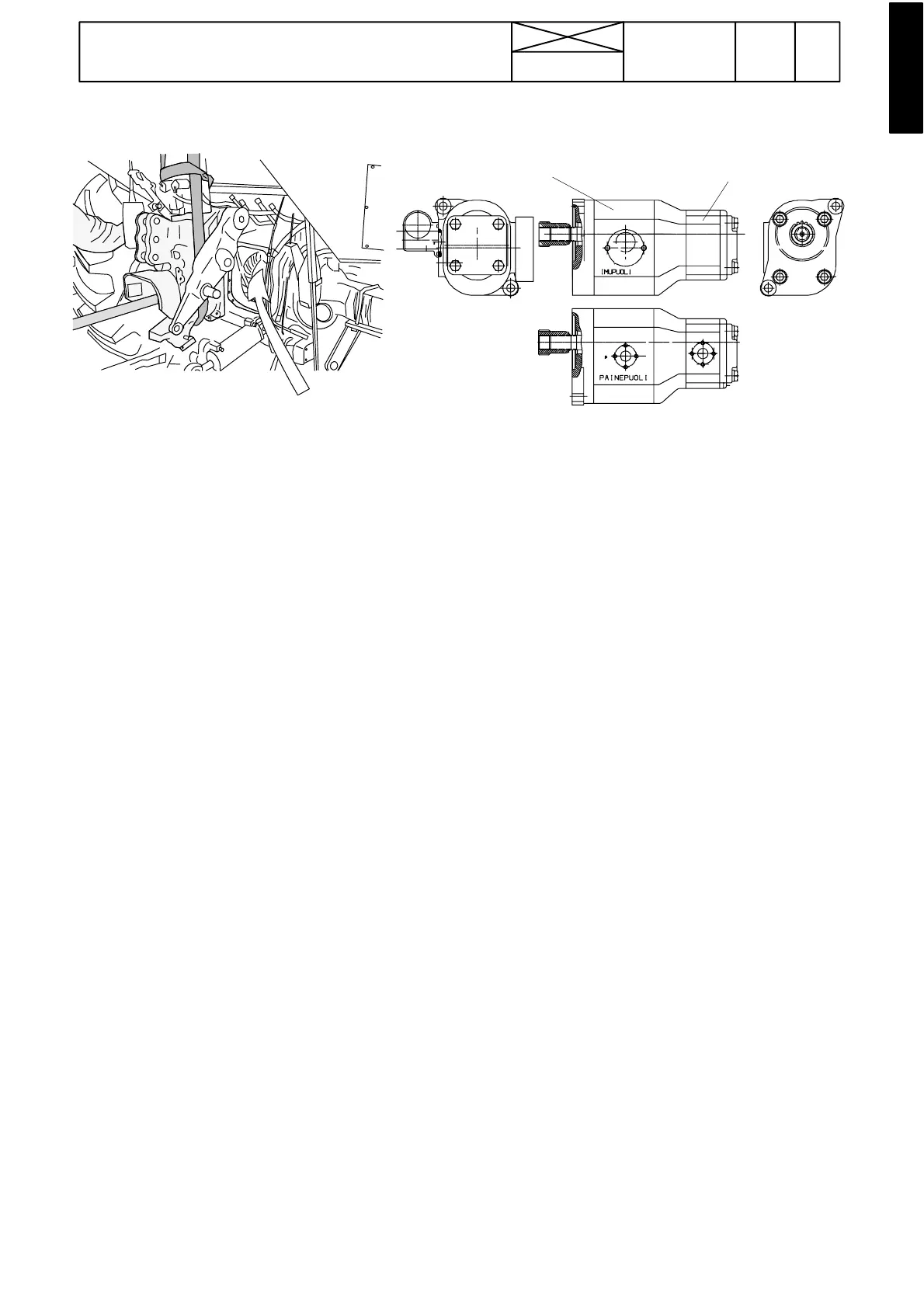

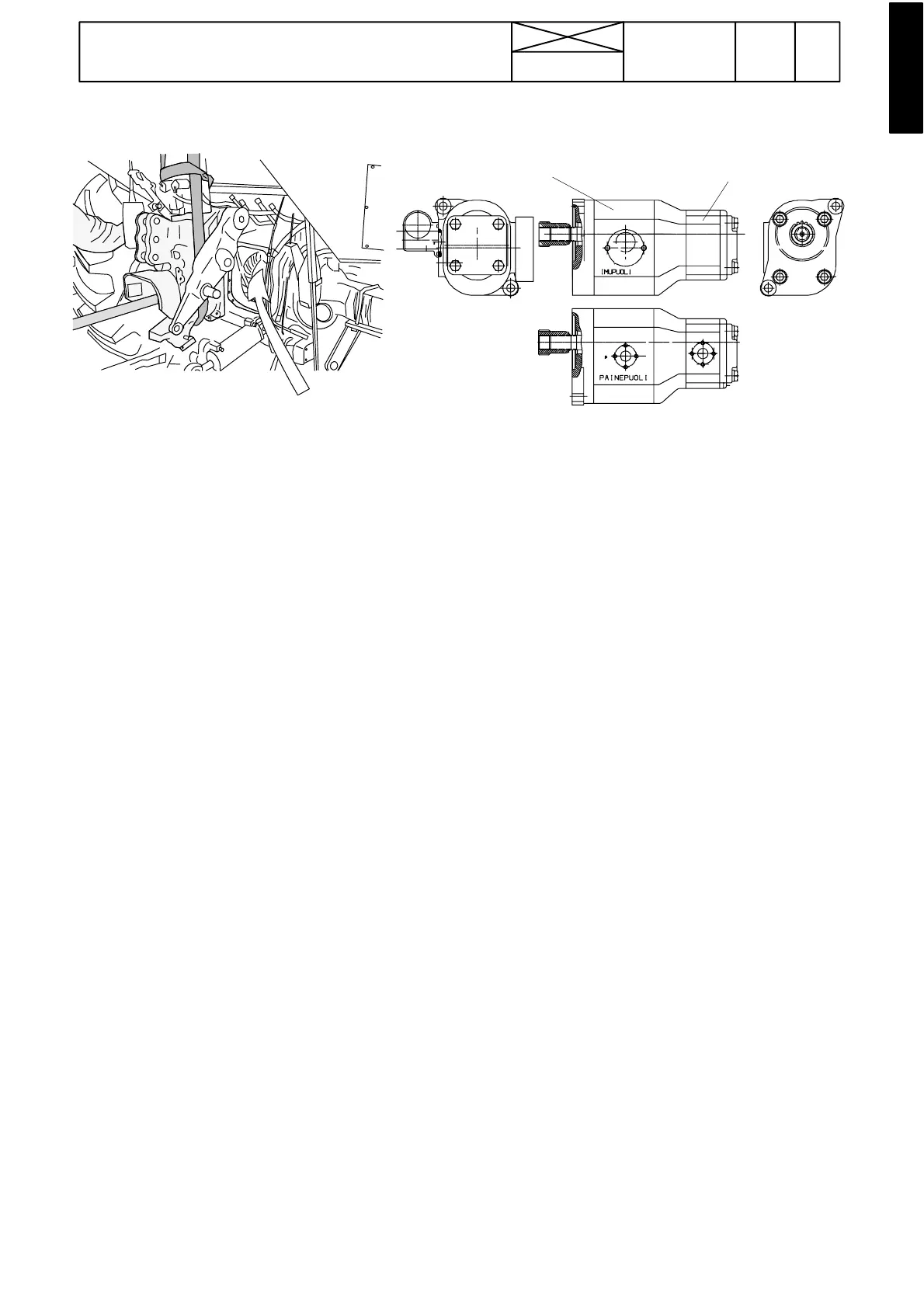

Position of pump

Technical data o f pump, see page 910/3

Removing and fitting pump, see page 911/3

Pump and pipes, see pages 910/11---11A

Low pressure pumpHigh pressure pump

A. General

The condition of the pump can be checked e.g. by measuring

pump output at different counterpressures. A wornpump has

a lowered output and it cannot maintain enough high pres-

sure. In this case the hydraulic circuit does not function as it

should.

The lowered output causesthe hydraulic cylindermovements

to be slower than normal.

The lowered pressure means that the hydraulic cylinder can-

not raise heavy loads. E.g. the lifting cylinder cannot raise the

load even thought its weight is below the max permissible

load.

A possible reason can also be a faulty pressure---limitingvalve

or shock valve. In addition, oil leaks in various components

and seals can also cause corresponding malfunctions.

The pump can be tested e.g. by measuring the pump output

with a flow meter. Use of a separate loading valve makes it

possible to measure the output at different pressures. The

pump output must not vary much at different counter pres-

sures. The working hydraulic pump output can be measured

from the quick---action couplings. The low pressure pump

output can be measured by connecting the flow meter on the

pressure hose between t he pump and the servo valve block.

It is difficult to determine a certain reject limit to the pump. In

a light agricultural use even a worn pump can function satis-

tactorily. Just when a tractor has extra hydraulic equipment

(front loader, timber loader etc.), a worn pump cannot main-

tain the hydraulic circuit and it should be changed.

B. Fault tracing by inspecting oil:

1. Air in oil --- If there is too much air in oil, the result is that oil

foams in the tank. In this case, check all seals and connectors

in the suction side. Also the suction strainer cover seal can be

faulty. Check the condition of the pump drive shaft oil seal.

Change oil if necessary.

2. Water in oil --- Water in oil causes the oil to be milky. The

system must be emptied and filled with new oil. In addition,

prevent water from entering into the hydraulic system. Water

causes corros ion to the various parts in the hydraulic circuit.

3. Impurities in oil --- Impurities can be verified by taking a

sample of oil and by pouring it through a filter paper. The suc-

tion strainer and the pressure filter should be serviced accord-

ing to the maintenance schedule. Impurities can enter into the

system from the auxiliary hydraulic cylinders. The hydraulic

oil and the pressure filter must be changed according to the

instructions.

4. Impaired properties of oil

--- Mineral oil loses some lubri-

cating properties in prolonged use. This can appear in

change of colour, change of smell or change of viscosity. For

these reasons, it is necessary to change the o il acco rding to

the maintenance program. Also oil level should be checked

regularly.

Loading...

Loading...