653

Model Code Page

41. Clutch

8. 11. 1990

6000--8750 411 5

Clutch disc splines

Coat the splines in the centre of the clutch disc with pressure---

resistant grease to safeguard the axial movement of the disc

on the clutch shaft.

Clutch disc rivets

Rivets have a small holefor freeair flow.If these holesbecome

clogged (e.g. dust), it can cause sticking of the disc.

Organic linings are made by winding asbestos---free band.

For that reason radial grooves must not be made on the li n-

ings because thus bands can cut off. This can cause the lin-

ings to loosen.

Friction surfaces must be clean. A small amount of grease on

the linings can cause vibrations and the disc can s tick.

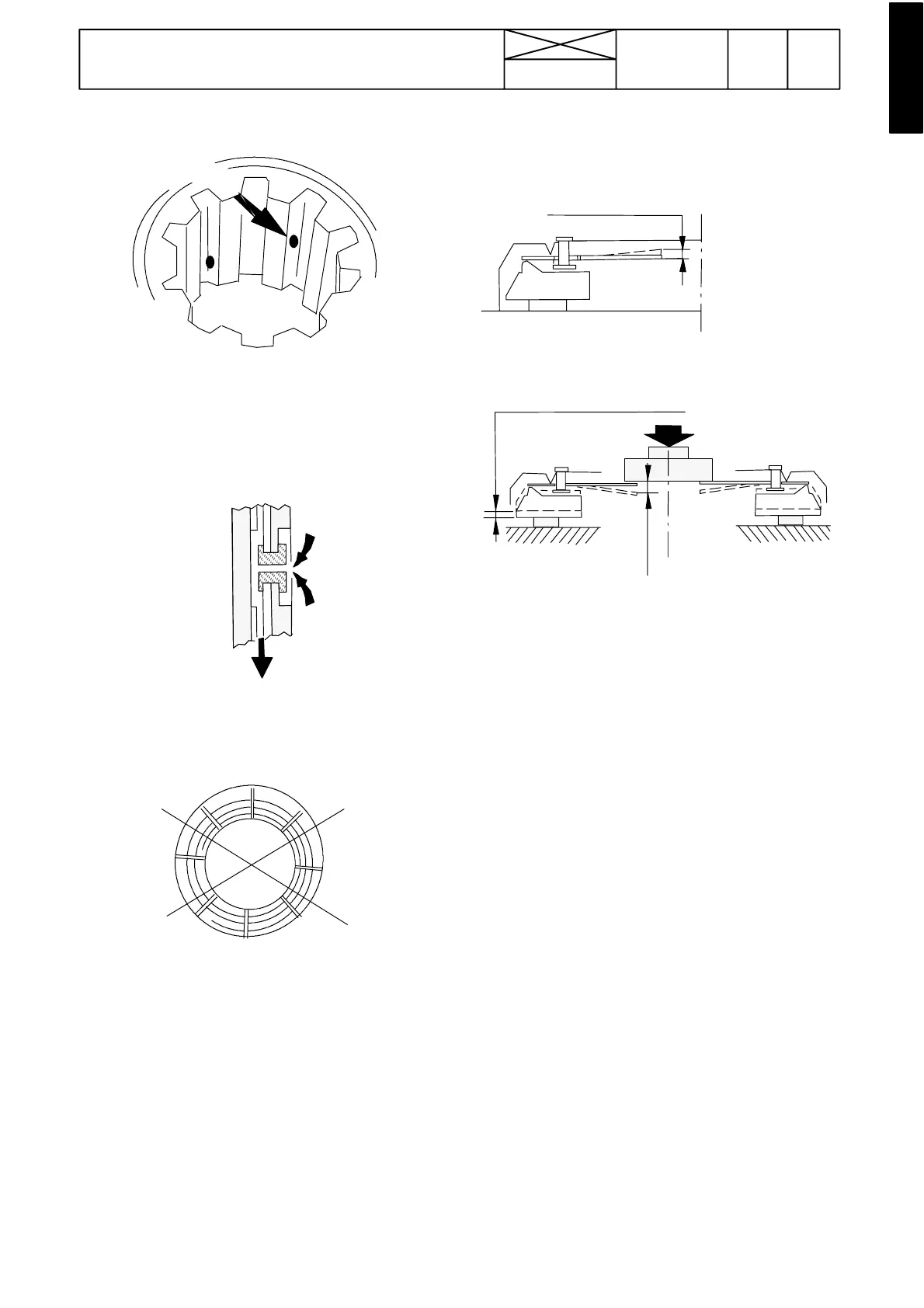

Checking movement of pressure plate

1. Place the clutch in fixture ETV 892 570 with 10 mm spacers.

Secure with at least four bolts.

ma

.0,8mm

min 1,9 mm

10 mm

2. Apply the clutch 3---4 times so that the cup spring ”beds

down”.

3. Check the height difference between the fingers of the cup

spring: this must not exceed 0,8 mm. If it is greater, the clutch

must be changed.

4. Press the cup spring fingers down by 10 mm and measure

the distance between the spacers and pressure plate. The

clearance must be at least 1, 90 mm. Check at several points.

If the clearance is lower the clutch must be changed.

Loading...

Loading...