834

Model Code Page

46. Power take ---off

1. 4. 1997

6000--8750 462 4

8. 11. 1990

D. Fitting PTO clutch shaft and adjusting

bearing clearances

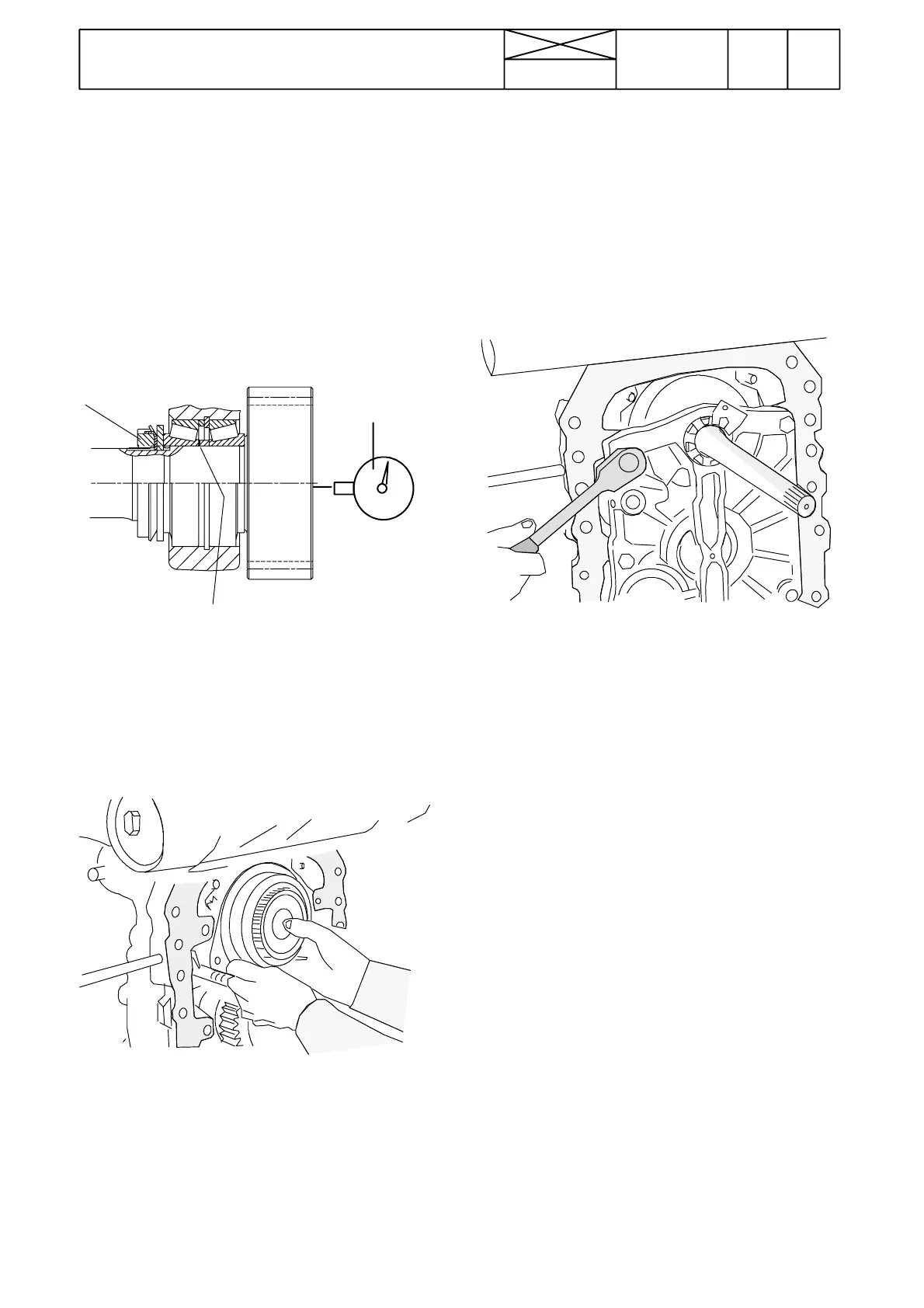

Adjusting bearing clearance of ground speed PTO shaft

(adjustment is done before fitting the front cover)

1. If you have changed the bearingsof the ground speed PTO

shaft (shaft is attached to the front cover), adjust the taper

roller bearing clearance as follows:

--- fasten the front cover to a vice

--- fit the old shims bet ween the bearings

--- Fit the spacer ring and tighten the shaft nut to 260---280

Nm.

--- Place a dial gauge stylus against the shaft rear end (middle

of the gear)

260---280 Nm

s= 0,10

0,15

(Z22)

Z24

0,025---0,075

--- Measure the clearance which should be 0,025---0, 075. Ro-

tate the shaft and press it to its extreme positions.

--- Increase or decrease shims thickness between bearings.

Note! Shim thickness of 0,10 and 0,15 mm are available.

Tighten the shaft nut after the front cover has been fitted.

2485

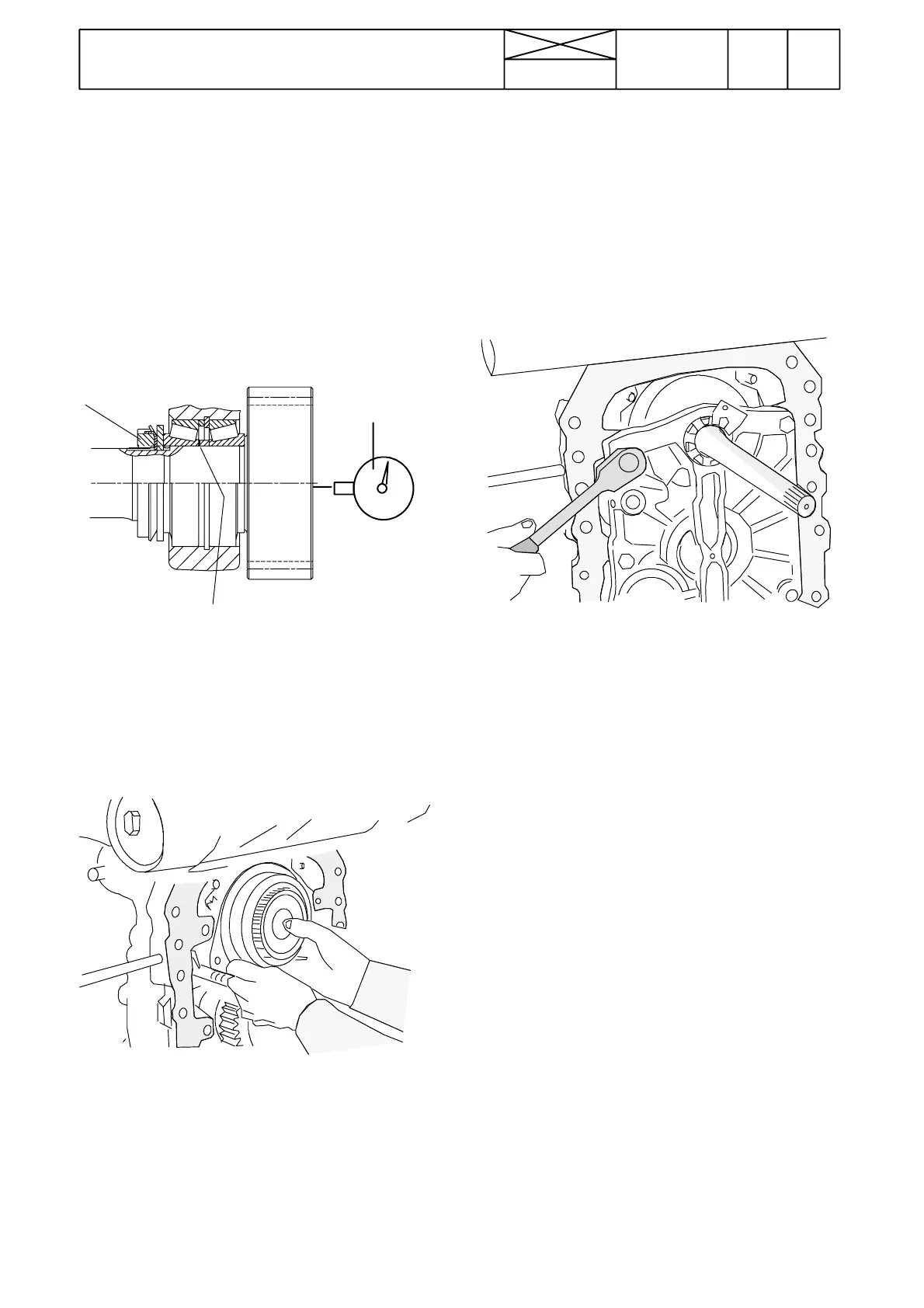

2. Fit the PTO clutch shaft into the housing. Do not damage

the piston ring type seals at the rear end of the shaft.

3. Place the clutch drum/shaft onto the clutch disc pack.

4. Fit drift ETV 894 080 into the hole for selector fork rail for

holding the locking spring and ball in place.

5. Fit the front cover and make sure that:

--- the selector forkrail is pushed through the hole on the cover

and that the rail pushes out the drift

--- the PTO shaft front end bearing is pushed into its location

on the cover

--- the brake plate holes engage with the pins on the cover.

2490

6. Tighten the cover bolts to a correct torque. Ensure that the

selector fork rail locking ball and spring are in place.

Note! Two bolts on the upper and lower corner of the cover

have a guide sleeve.

7. When the cover is in place, tighten the ground speed PTO

shaft nut to 260---280 Nm and lock it with a locking washer.

Loading...

Loading...