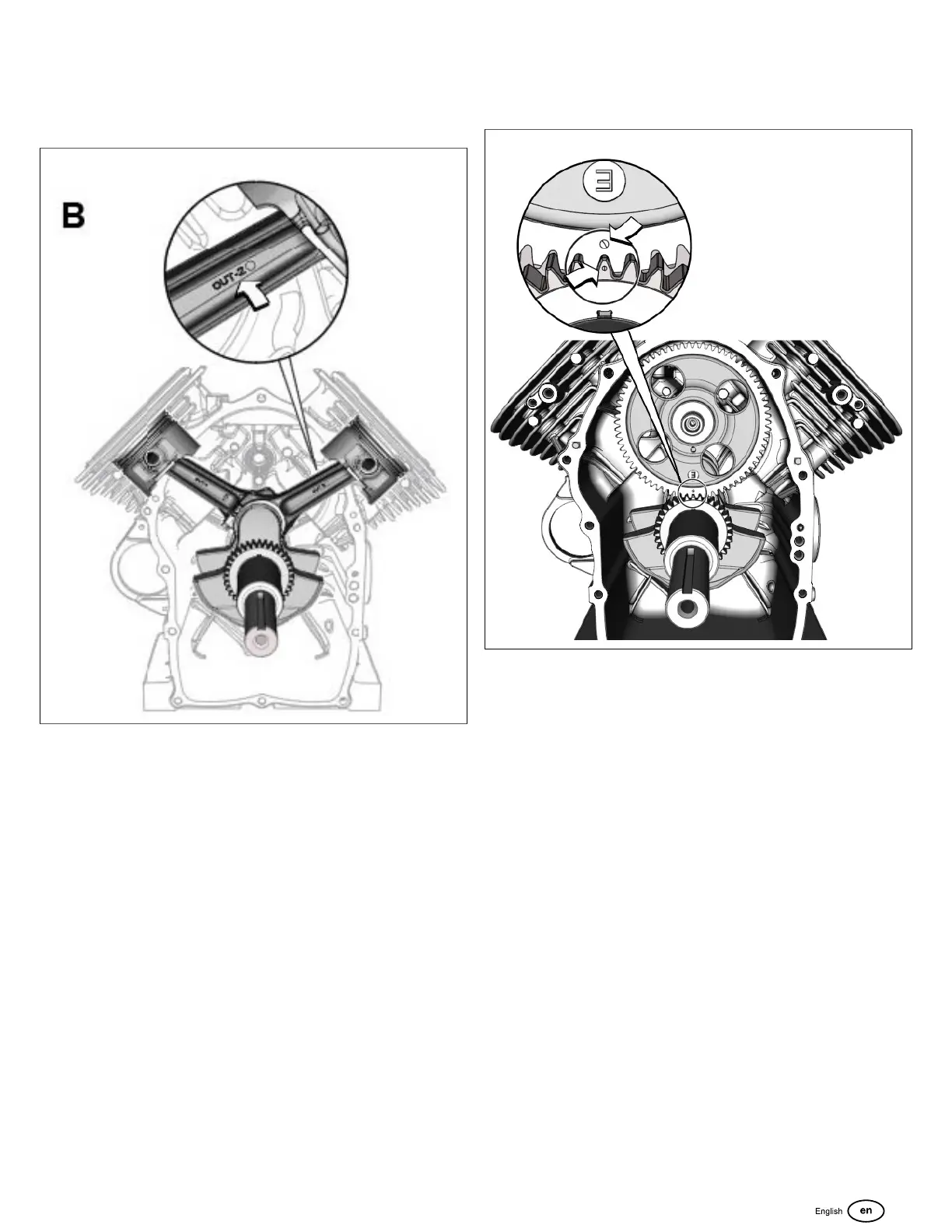

15. Start piston/connecting rod assembly into cylinder 2

bore, so that the rod stamp OUT-2 is visible through

thecrankcase cover opening (B, Figure 150), and the

locating dot on the piston crown is on the MAG bearing

side. Repeat steps 13-17.

150

16. Rotate crankshaft two revolutions to be sure crankshaft,

connecting rods, and pistons move freely without binding.

17. Move connecting rods sideways to verify clearance on

each side of crank pin journals.

18. Thoroughly lubricate tappet bores and tappet shafts with

clean engine oil.

19. Install tappets into tappet bores. Be sure to install each

tappet in the same bore from which it was removed.

20. Lubricate the camshaft MAG bearing journal, camshaft

lobes, and camshaft bearing bore in crankcase with

clean engine oil.

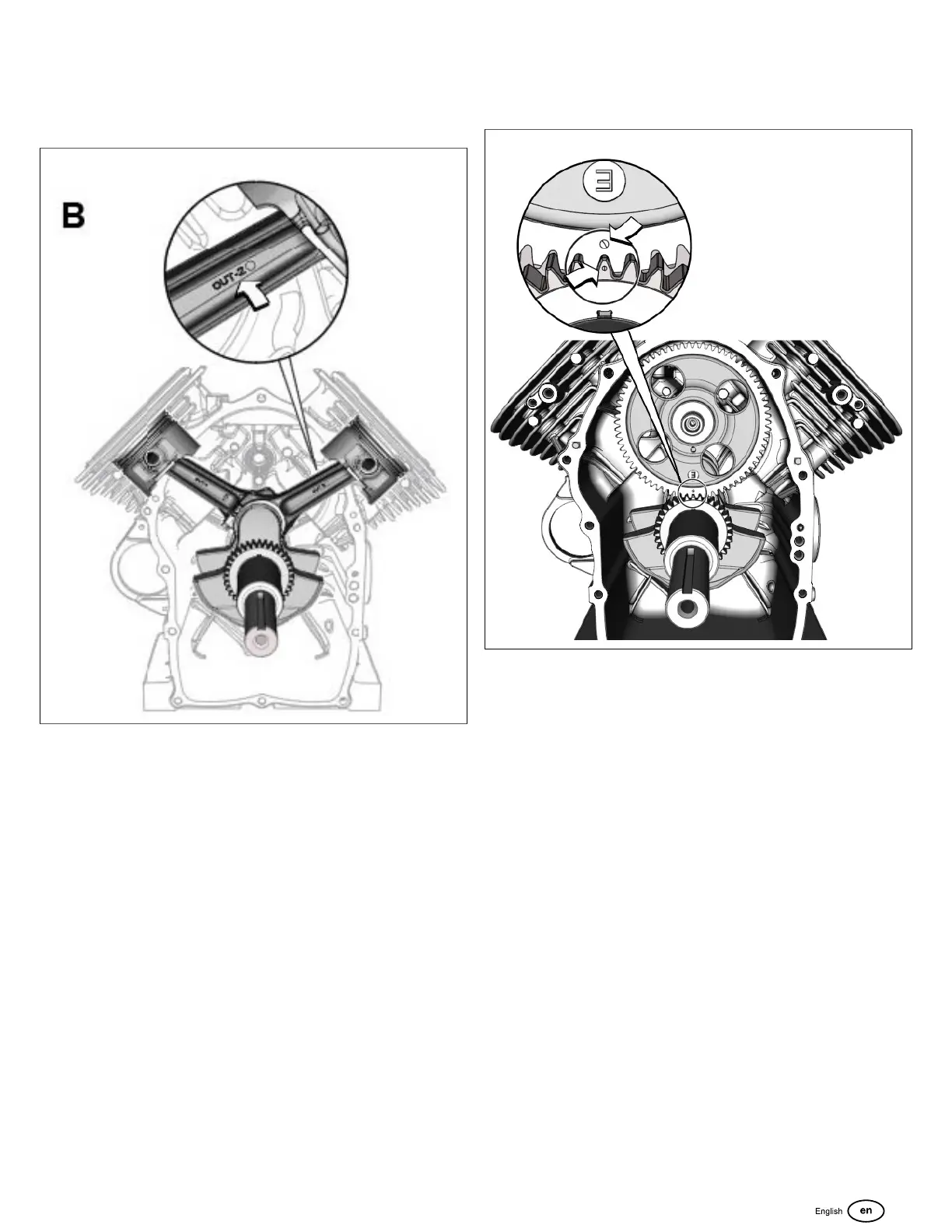

21. Verify that valve tappets are clear of camshaft lobes, and

install camshaft into bearing bore aligning timing mark on

camshaft gear root with timing mark on crankshaft gear

tooth See Figure 151.

151

22. Lubricate the camshaft and crankshaft gear meshwith

clean engine oil.

23. Verify that mating surfaces of crankcase and crankcase

cover are clean and dry. Any dust or dirt left on mating

surfaces can cause leaks.

121

Loading...

Loading...