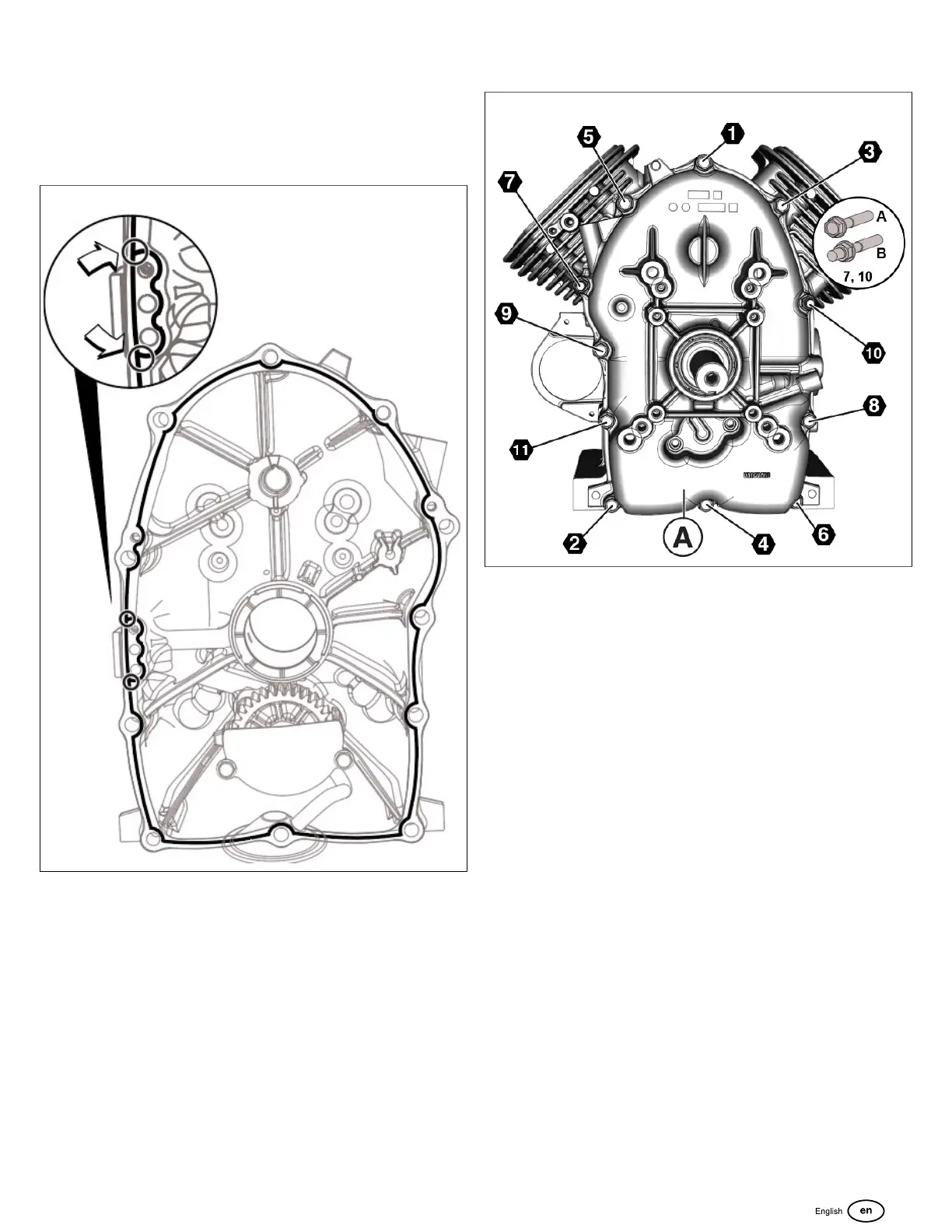

29. See Figure 154. Install steel core gasket, if used, or

apply a bead of Silicone Sealant (see SECTION 9 -

SPECIFICATIONS - Lubricants and Sealants) 0.06-0.10

inches (1.5-2.5 mm) thick to crankcase cover. Bead

must be a continuous closed loopwith no gapsand an

overlapnot exceeding 0.20 inches (5 mm) in thetwo

areas shown.

154

NOTE: Crankcase cover must be installed within five minutes

of application. If time limit is exceeded, scrape off silicone

sealant and reapply.

30. Install oil seal protector sleeve on crankshaft.

NOTE: Use black electrical tape if oil seal protector sleeve is

not available.

31. Install crankcase cover onto 2 locating pins.

32. Remove oil seal protector sleeve (or black electrical tape)

from crankshaft.

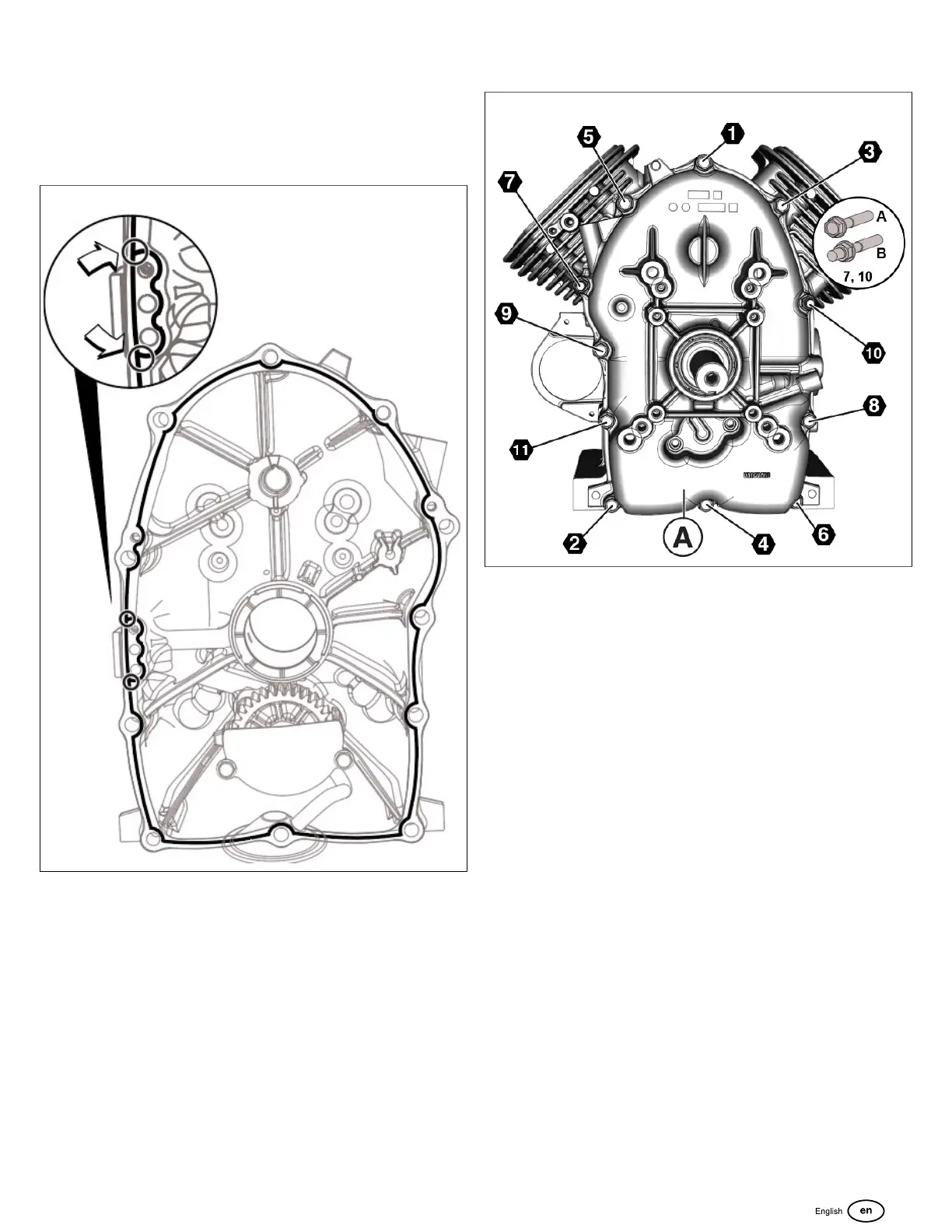

33. Start 11 fasteners to secure crankcase cover (A, Figure

155) to crankcase. Proceed as follows:

155

NOTE: See inset of Figure 155. In lieu of the standard screw

in positions 7 and 10, install the threaded stud, if equipped

with the optional muffler bracket support.

NOTE: Verify cleanliness of crankcase cover screws. Friction

caused by dirtand debris will result in a false torque reading.

A. Tighten bolts to 65 lb-in (7.3 Nm) using the

sequence shown in Figure 155.

B. Tighten bolts to 130 lb-in (14.7 Nm) using the

sequence shown.

C. Final tighten bolts to 195 lb-in (22 Nm) using the

sequence shown.

NOTE: Failure to step-torque bolts in the proper sequence

may result in gasket leaks or cause the crankcase cover to

warp.

34. Rotate crankshaft to check for binding.

123

Loading...

Loading...