Operating manual Manual powder spray gun PEM-X1

6 Assembly and Commissioning

Order number 2326020 | Edition 10/2022 25

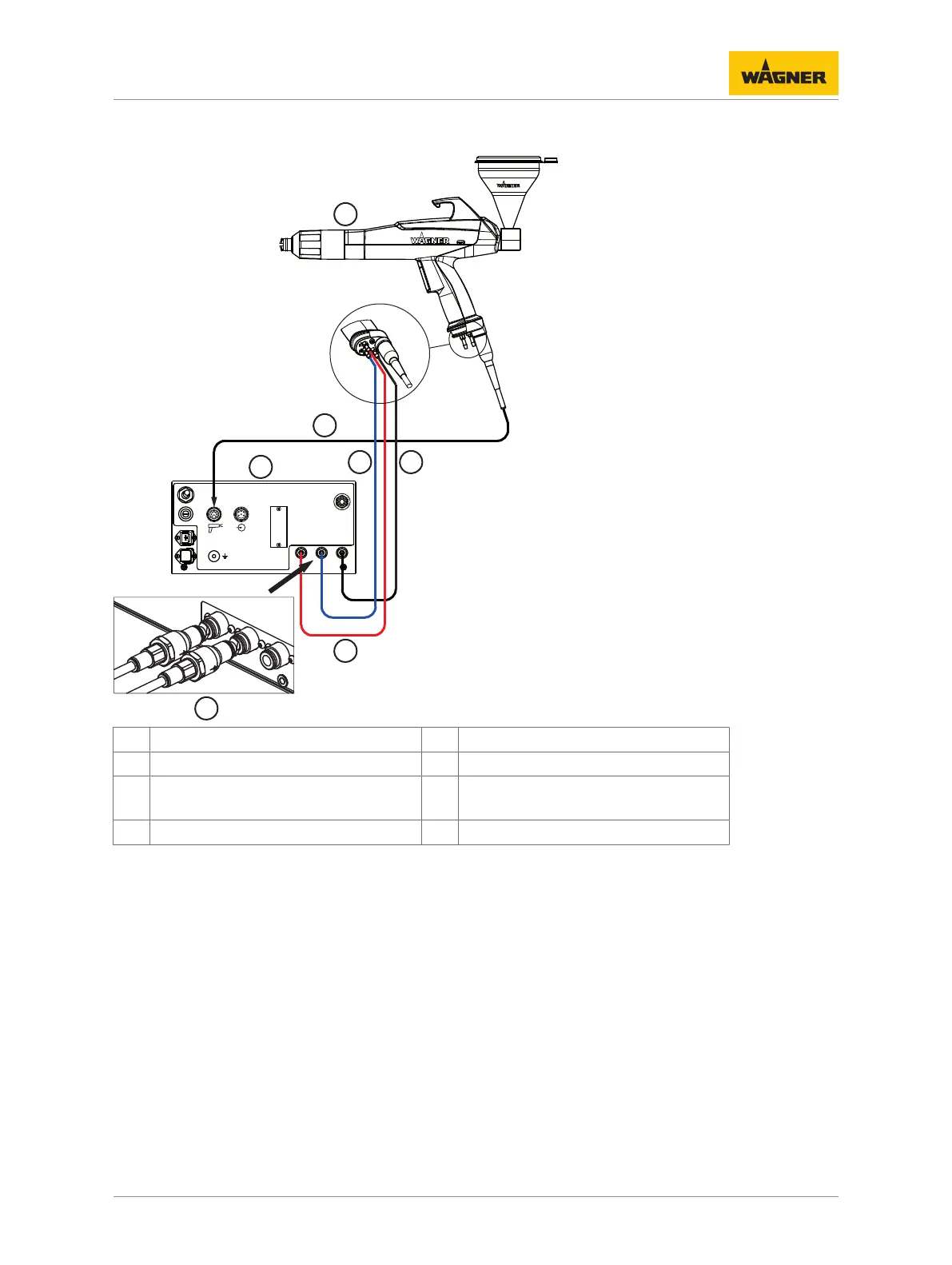

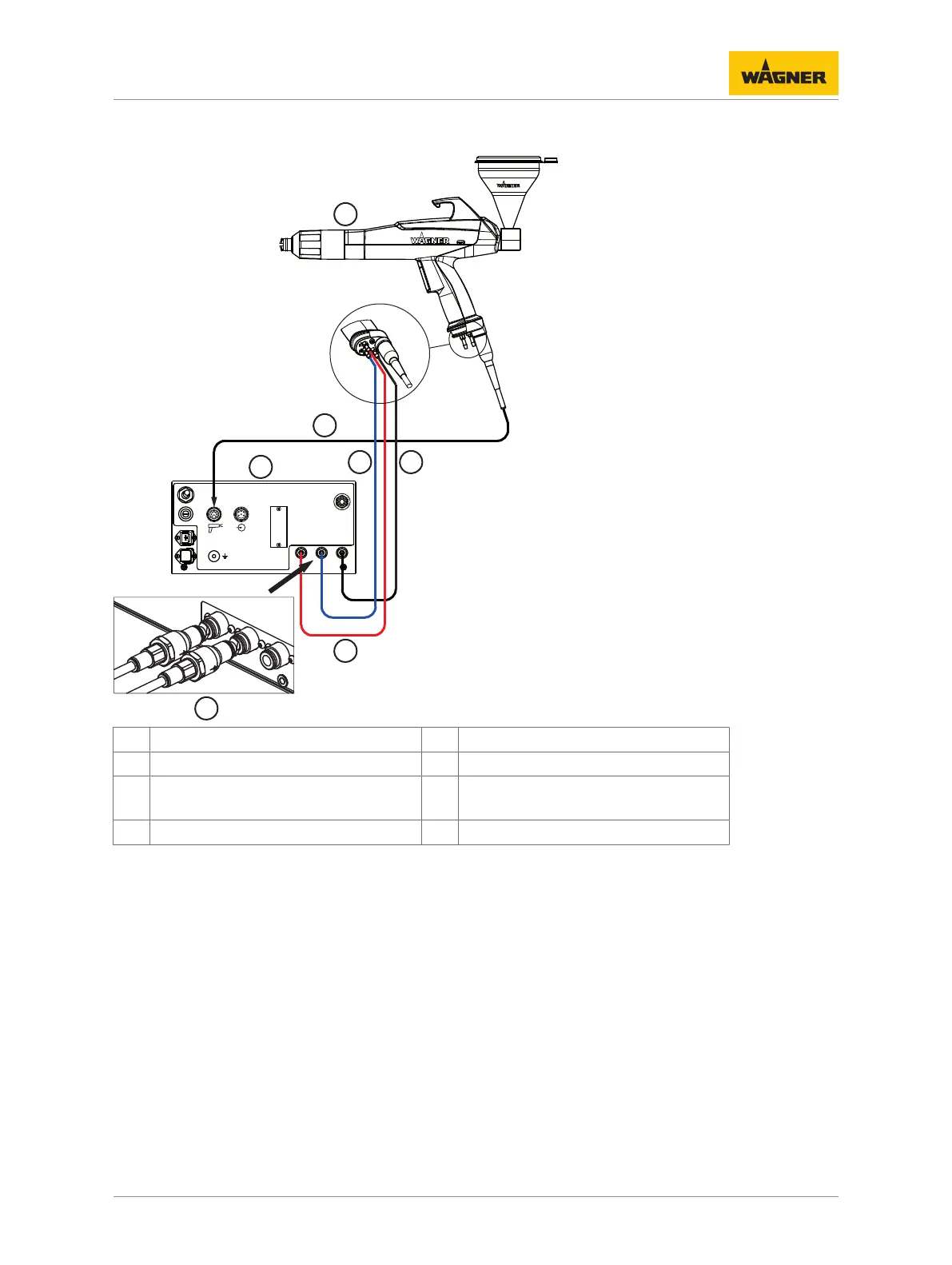

6.6 GROUNDING

For safety reasons, the control unit must be properly grounded. The grounding connection

to the energy supply (socket) is made via the mains connection cable's protective conductor,

while that to the work piece/system is made via the knurled screw on the rear of the control

unit. Both connections are absolutely essential. The gun is grounded according to

instructions for proper commissioning.

Good grounding of the work piece is also necessary for optimum powder coating.

A poorly grounded work piece causes:

– dangerous electric charging of the work piece

– very bad wrap-around

– uneven coating

– back spraying to the spray gun, i.e., contamination

Prerequisites for perfect grounding and coating of a work piece are:

– Clean suspension of the work piece to be coated.

– That a grounding resistance of the work piece of 1 MΩ is not exceeded

(resistance to ground measured at 500 V or 1000 V).

Sparks between conveyor, conveyor hooks (hangers) and work piece can occur if

electric contact points between conveyor, conveyor hooks (hangers) and work piece

are not sufficiently cleaned and therefore the work pieces are not sufficiently

grounded! These sparks can cause heavy radio frequency interference (EMC).

6.6.1 Grounding the powder coating system

1 Only use mains cables with grounding strand!

2 Connect grounding cable with booth or spray wall and signal ground!

3 Connect grounding cable to an uncoated metal part of the booth or spray wall!

4 Remove all paint from hooks and other hanger parts!

5 Do not wear insulating gloves!

6 Wear electrostatically conductive footwear!

7 The floor must be electrostatically conductive!

Loading...

Loading...