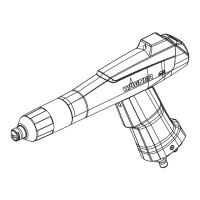

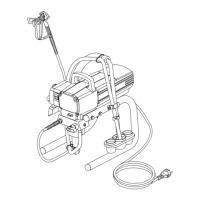

Operating manual Manual powder spray gun PEM-X1

6 Assembly and Commissioning

Order number 2326020 | Edition 10/2022 21

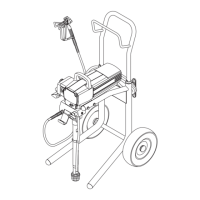

6 ASSEMBLY AND COMMISSIONING

6.1 TRAINING OF ASSEMBLY/COMMISSIONING PERSONNEL

4 The assembly and commissioning personnel must have the technical skills to safely

commission the device.

4 When assembling, commissioning and carrying out all work, read and follow the

operating manuals and safety regulations for the additionally required system

components.

A skilled person must check to ensure that the device is in a reliable state after it is

assembled and commissioned.

6.2 STORAGE CONDITIONS

Until the point of assembly, the device must be stored in a dry location, free from vibrations

and with a minimum of dust. The device must be stored in closed rooms.

The air temperature at the storage location must be between -20°C and +60°C (-4°F and

+140°F).

The relative air humidity at the storage location must be between 10 and 95% (without

condensation).

6.3 INSTALLATION CONDITIONS

The air temperature at the installation site must be in a range between 0°C and 40°C; 32°F

and 104°F.

The relative air humidity at the installation site must be between 10 and 95% (without

condensation).

6.4 PREPARATION OF THE SPRAY GUN

6.4.1 Selection of a Suitable Nozzle System

The process of changing from the flat jet nozzle to the deflector cone is described in Chapter

Changing Nozzle Types [839].

You will find the article numbers of the different nozzles in Chapter Accessories [847].

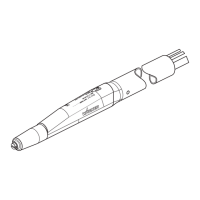

Nozzle Application overview Powder cloud

Flat jet nozzle

Complex part geometries

Flat work pieces (reduced

picture frame)

Profile

Undercuts

Widely spread flat powder cloud

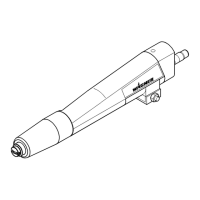

Deflector cone

Wire goods

Grid designs

Small components

Round powder cloud

Size of the powder cloud is de-

pendent on the deflector plate

diameter

Loading...

Loading...