Operating manual Manual powder spray gun PEM-X1

9 Troubleshooting and Rectification

Order number 2326020 | Edition 10/2022 43

9 TROUBLESHOOTING AND RECTIFICATION

DANGER

Incorrect maintenance/repair!

Danger to life and equipment damage.

4 WAGNER devices, protective systems and safety, monitoring and control equipment

may only be serviced/repaired as defined in Directive 2014/34/EC (ATEX) by trained

WAGNER service personnel or skilled persons in accordance with TRBS 1203! Note

national regulations!

4 Service, repair or replacement of devices or parts of devices may only be performed

outside the hazard area!

Malfunction Cause Rectification

No electrostatic (e.g., no wrap

around or no powder adhesion)

Fault in the high-voltage genera-

tor

Contact a WAGNER service center

Electrical cable from gun to con-

trol unit faulty

Contact a WAGNER service center

Cascade in gun faulty Contact a WAGNER service center

Poor powder wrap-around, back-

spray

Insufficient or no grounding See chapter Grounding [825]

Spray pattern is uneven Parts of nozzle system worn Replace worn parts

Cracks in the gun housing Improper handling of the powder

spray gun

Gun housing must be replaced

Contact a WAGNER service center

Powder outlet uneven or inade-

quate

Contamination Blow through powder feeding

parts

Powder sintering Clean powder feeding parts

Feed unit contaminated See operating manuals for the re-

lated devices connected

Feed air / dosing air ratio incorrect Adjust at control module resp.

control unit

Wear on powder injector nozzle Replace worn parts on powder in-

jector ¹)

1.) You will find the wear parts and spare parts in the powder injector operating manual.

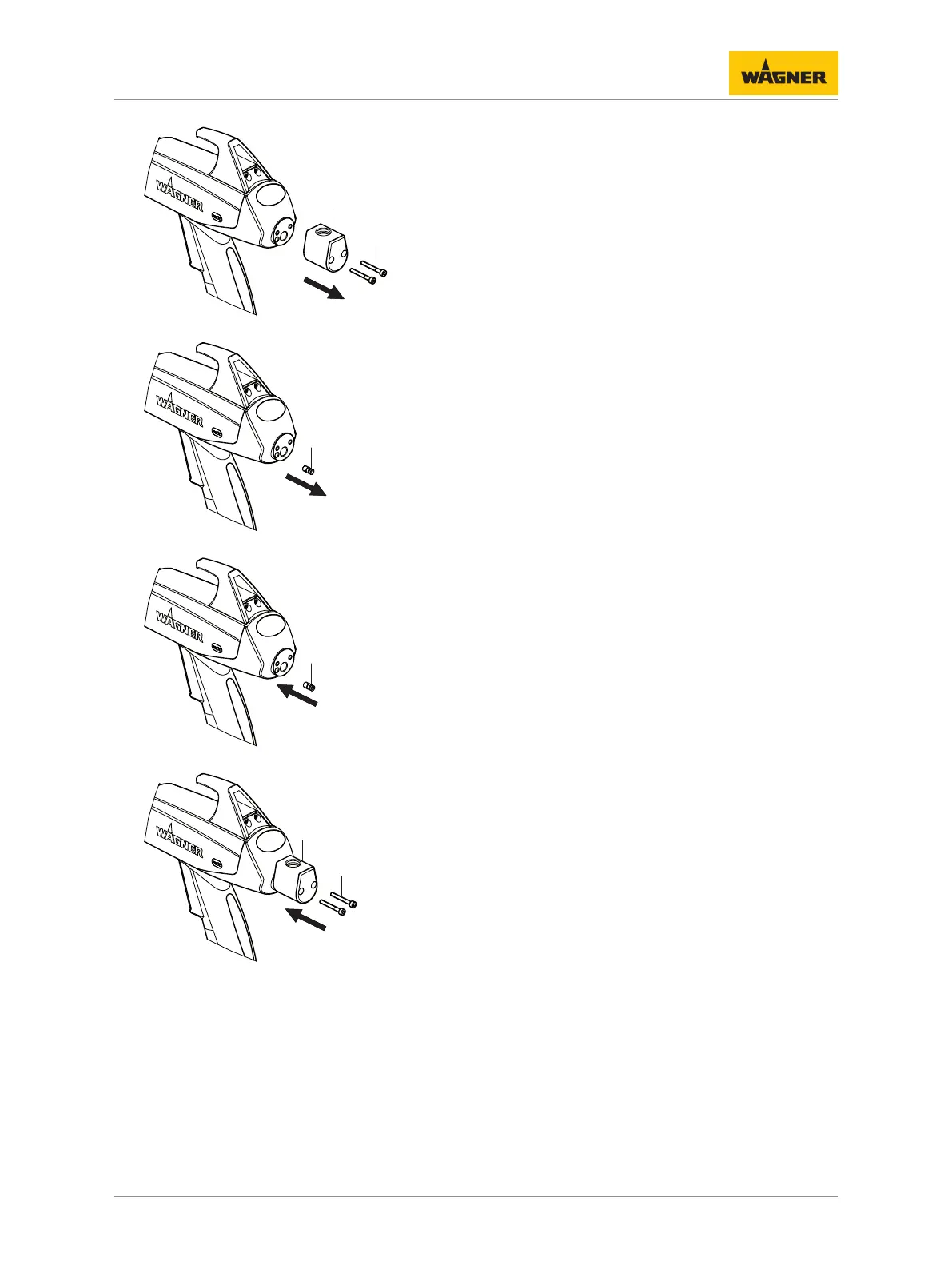

Loading...

Loading...