120

wallaceperimetersecurity.comPhone: 866.300.1110

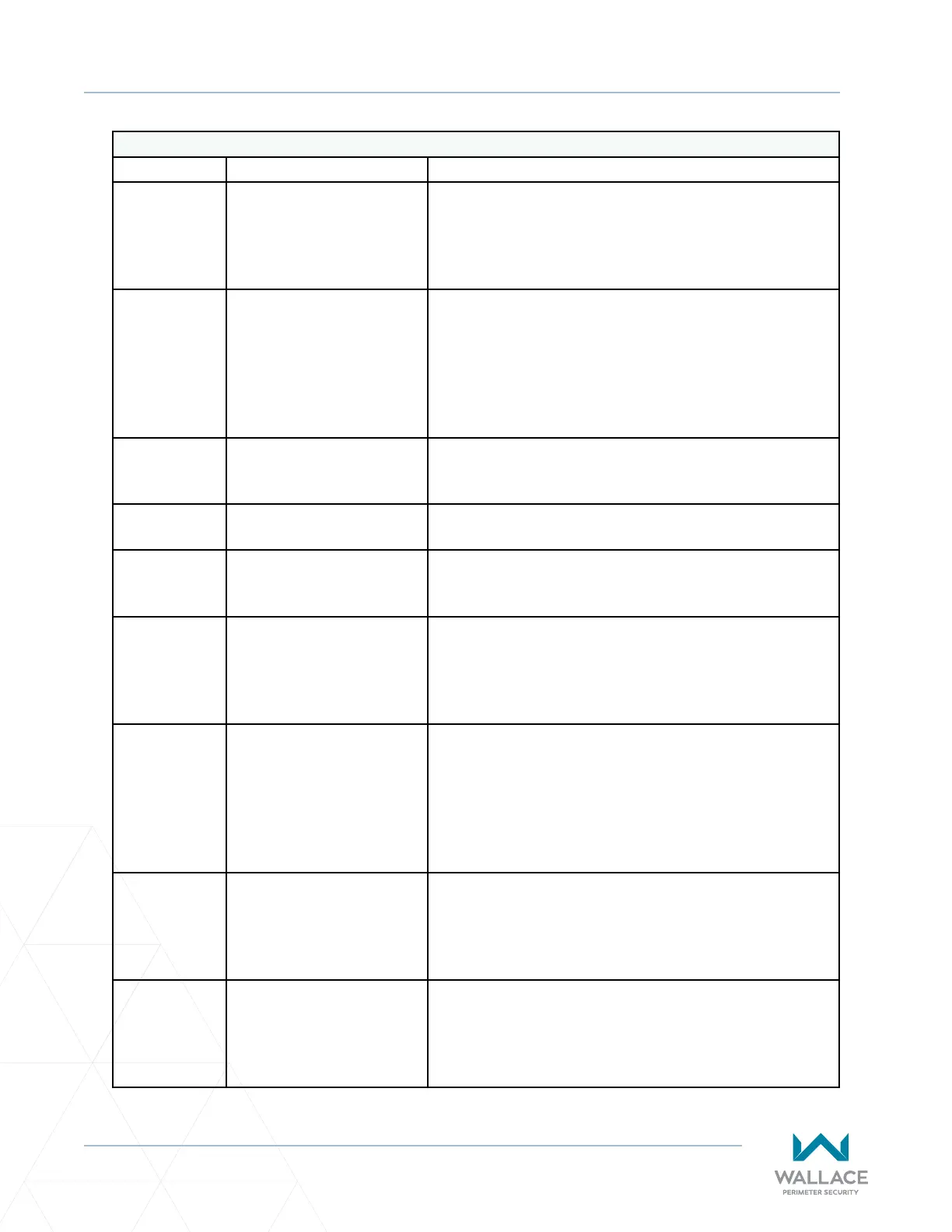

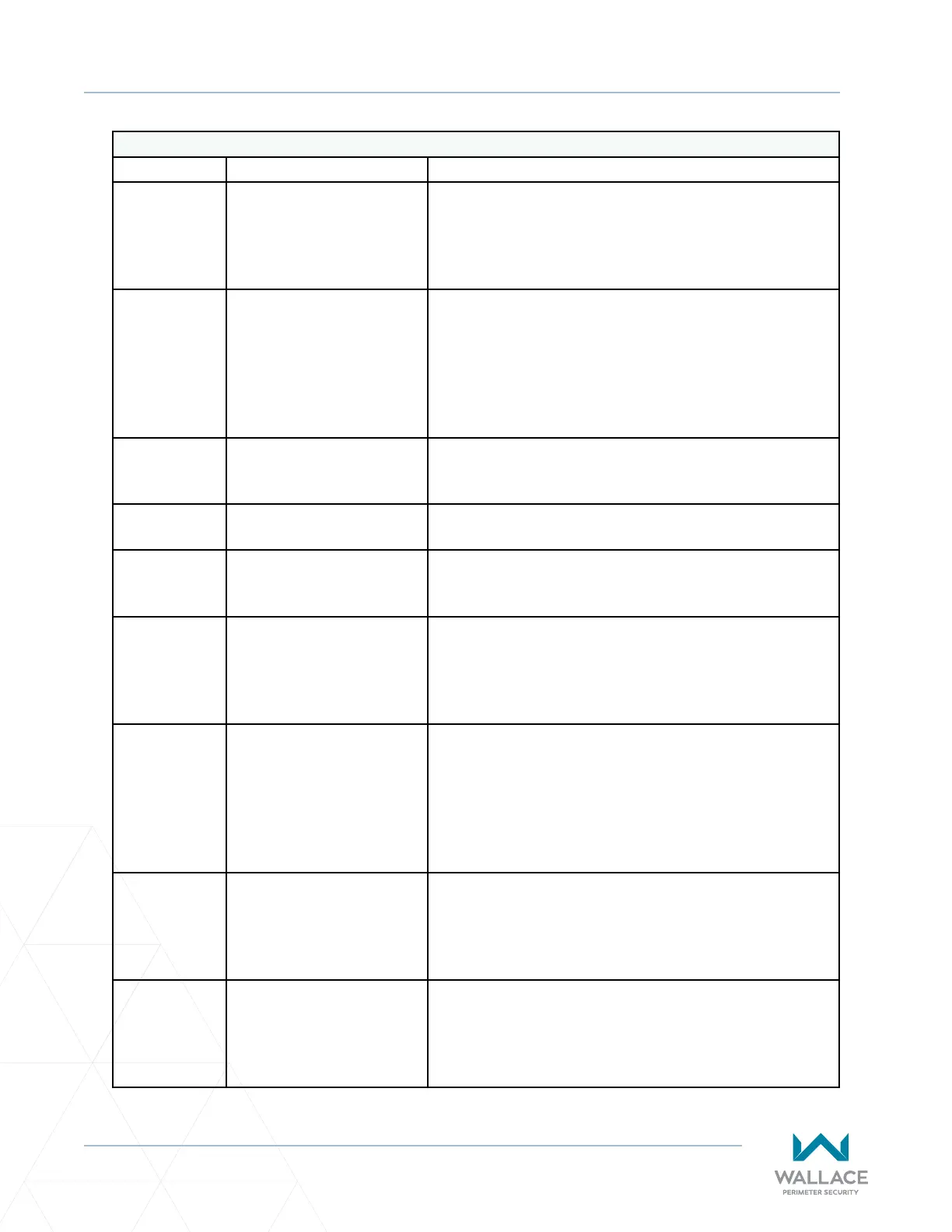

TROUBLESHOOTING

Safety Circuit Faults

Error Descripon Cause

F�364

Safety edge tesng failed. ‒ Safety edge was not acvated as expected when

requesng a test.

‒ The me between request for tesng and actual

tesng not synchronized.

F.365

Redundancy error with

interrupon.

‒ One of the processing channels for interrupon

detecon does not react idencally with the

second channel.

‒ Controller board defecve.

‒ Dynamic opcal system safety edge connected

but not set in Parameter P�460.

F�366

Too high a pulse frequency

for opcal safety edge.

‒ Defecve opcal safety edge.

‒ Defecve input for internal safety edge.

F�369

Internal safety edge

incorrectly parameterized.

An internal safety edge is connected but deacvated.

F�371

Number of edge trips for

external safety edge has

reached set limit.

Parameterized, maximum number of safety edge trips

during a gate cycle was exceeded.

F�372

Redundancy error with

short circuit.

‒ One of the processing channels for short circuit

detecon does not react idencally with the

second channel.

‒ Controller board defecve.

F�373

Fault in the safety edge

(message comes from

module).

‒ Cable break to safety edge, no edge connected,

edge terminaon resistor incorrect or defecve.

‒ Jumper for terminaon resistor in wrong posion.

‒ Safety edge processing selected with Parameter

P�470, but module not plugged in or wrong

module.

F�374

Safety bar tesng failed. ‒ Pre-limit switch for safety edge incorrectly set or

defecve.

‒ Processing module defecve.

‒ Safety edge defecve.

F�379

Safety edge detecon

defecve (coding pin or

parameter seng).

‒ No module plugged in but was reported as present

by a parameter.

‒ The controller was started up with a dierent

module than the one currently plugged in.

Loading...

Loading...