IntroductIon

© WASP S.r.l.

7

72

Use of the printer

7

8.11. Temperature controls

ATTENTION:

Pay particular attention during the various stages of the procedures, it is essential to wear safety

gauntlets to avoid the risk of burns.

NOTE:

The temperature controls are already set inside the official printing profiles.

NOTE:

The extruder allows to manage two distinct temperatures for preheating and for the nozzle.

Material manufacturers can provide useful information on the ideal temperature ranges to maintain

for each material.

The machine allows several temperature controls and it’s very important to manage them correctly in order to

get a good quality output.

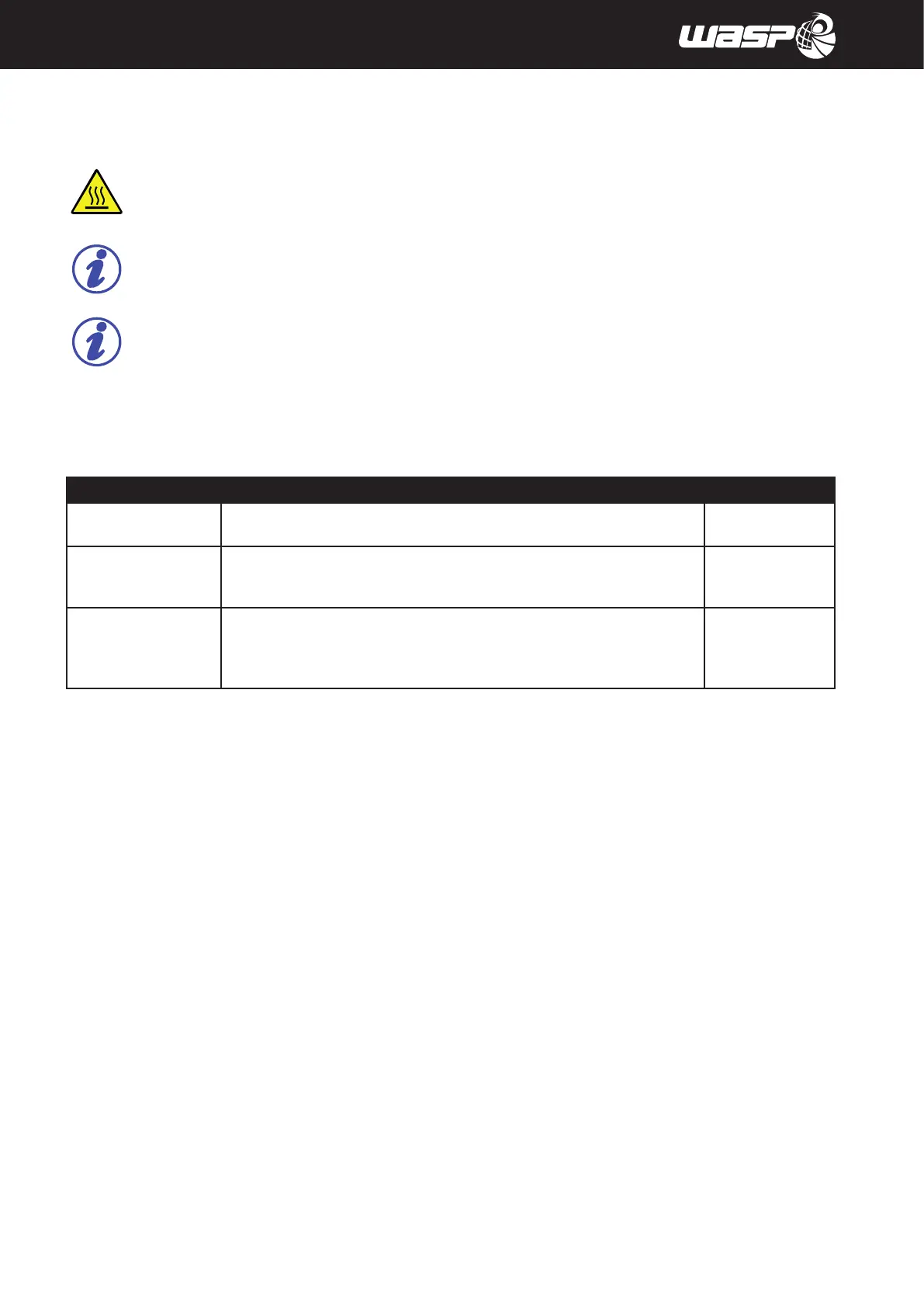

Control Description Max value

Nozzle Temperature of the nozzle, controls the melting of the pellets and the

consistency of the material extruded

350 °C

Barrel Preheat zone before the nozzle, it starts softening the pellets before the

complete melting

Always equal or

lower than the

nozzle

Firecap Blows hot air distributed on the top of the print, maintaining a high

temperature on the last layer printer and slowing down the cooling

process. This can prevent delamination, reduce the warping and ensure

optimal layer bonding.

150 °C

The temperatures can be managed:

• during the creation of the gcode in the slicing software

• with the TFT interface of the machine, see 5.2.1 Main Board

• with the printing server when the machine is connected to the network, see 8.8 Network and printing server

Loading...

Loading...