3 Maintenance procedures

This section provides the maintenance guidelines and procedures necessary to maintain the

device's performance.

Keep to a maintenance schedule, and perform maintenance as required and described in this

section.

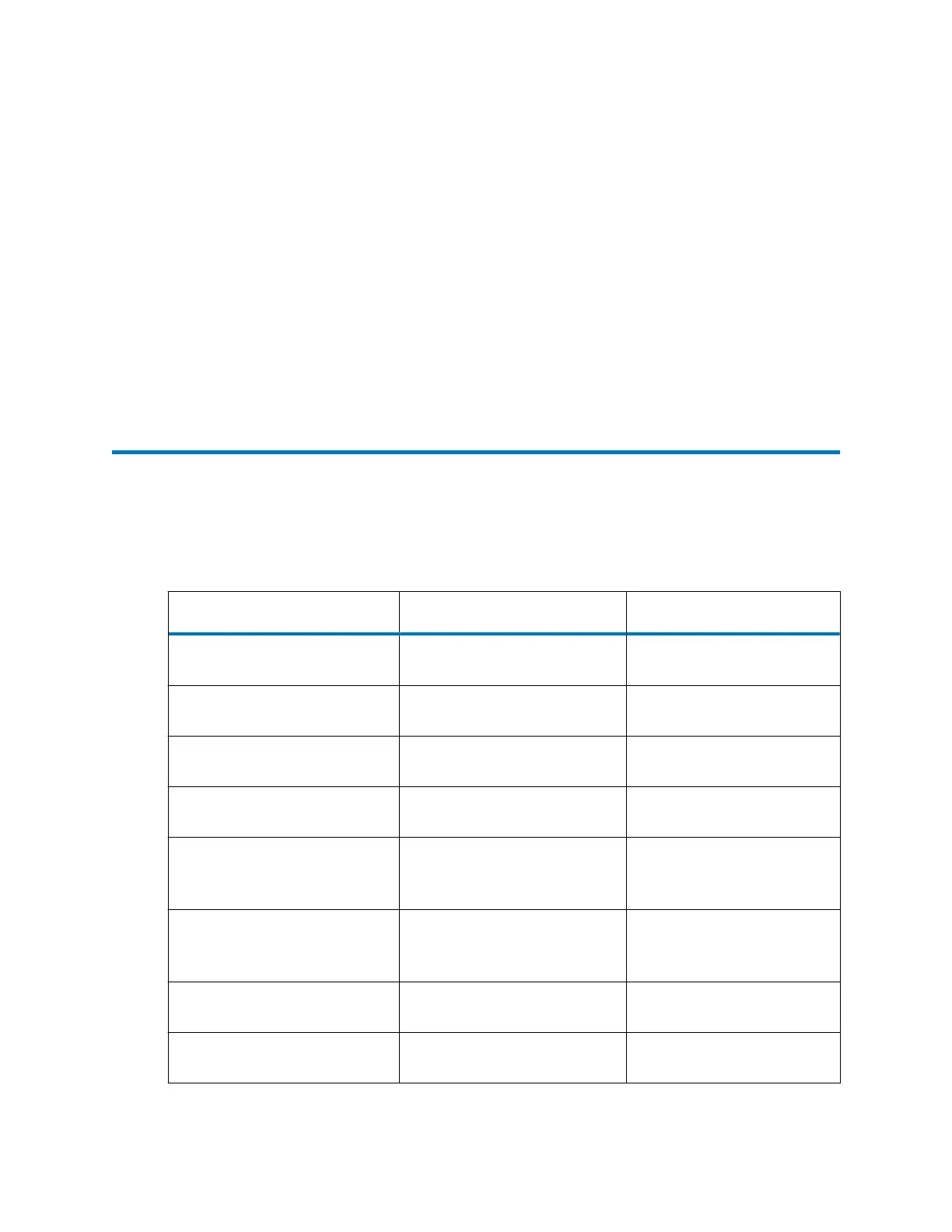

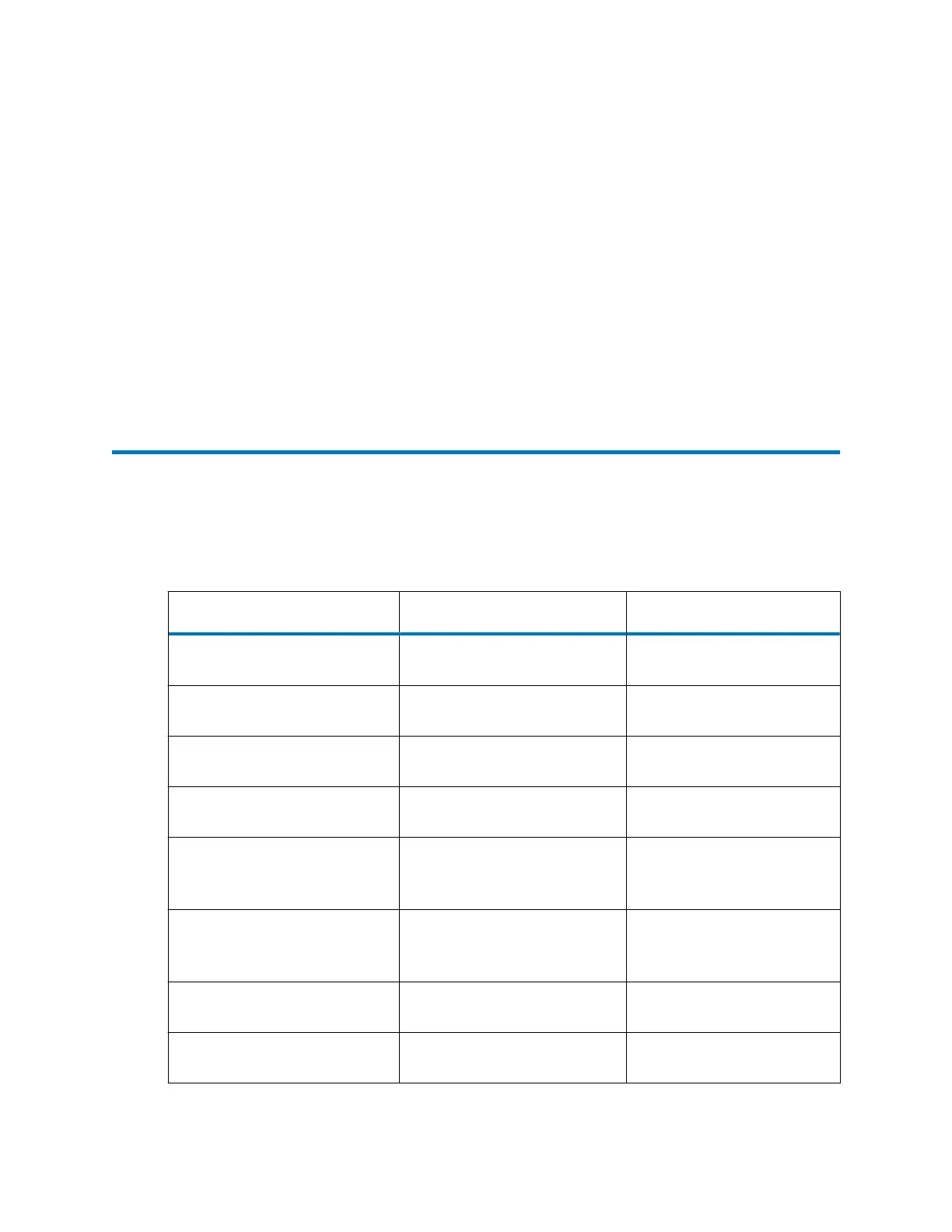

3.1 Maintenance schedule

The following table lists periodic maintenance schedules that ensure optimum instrument

performance.

The maintenance frequencies shown apply to instruments that normally receive moderate use.

Table 3–1: Maintenance schedule

Procedure Frequency Additional information

Clean the instrument case. As required. See Cleaning the instrument

case.

Empty the exhaust trap bottle in

the instrument exhaust line.

Check daily, empty as

required.

See Emptying the nitrogen

exhaust trap.

Empty the liquid trap bottle in

the backing pump exhaust line.

Check daily, empty as

required.

See Emptying the liquid-trap

bottle.

Gas ballast the rotary backing

pump. (Performance QDa only.)

ESI–weekly. See Gas ballasting the rotary

backing pump.

Inspect and adjust the rotary

backing pump's oil level.

(Performance QDa only.)

Weekly. See Maintaining the rotary

backing pump’s oil.

Change the rotary backing

pump oil. (Performance QDa

only.)

Annually. See Maintaining the rotary

backing pump’s oil.

Clean the source components. When sensitivity decreases to

unacceptable levels.

See Cleaning the source

components.

Replace the probe. When sensitivity decreases to

unacceptable levels.

See Removing and refitting

the source enclosure.

June 15, 2017, 715003956 Rev. F

Page 25

Loading...

Loading...