www.Wayne-Dalton.com

349981 REV2_05/17/2016

©

Copyright 2016 Wayne Dalton, a division of Overhead Door Corporation

10

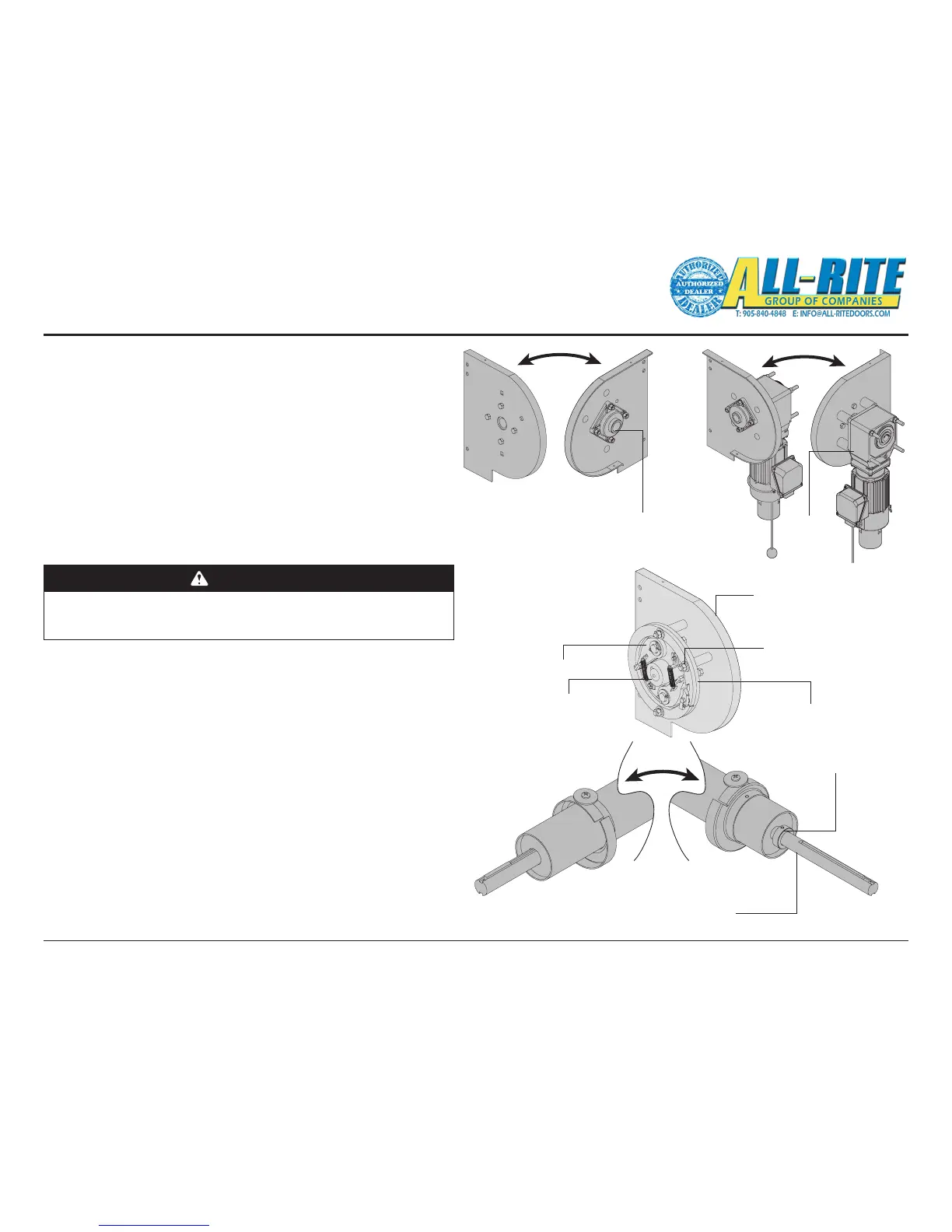

3. IDENTIFY HEADPLATE BRACKETS, Fig. 4–D(a)

Right hand drive is shown (left hand drive opposite).

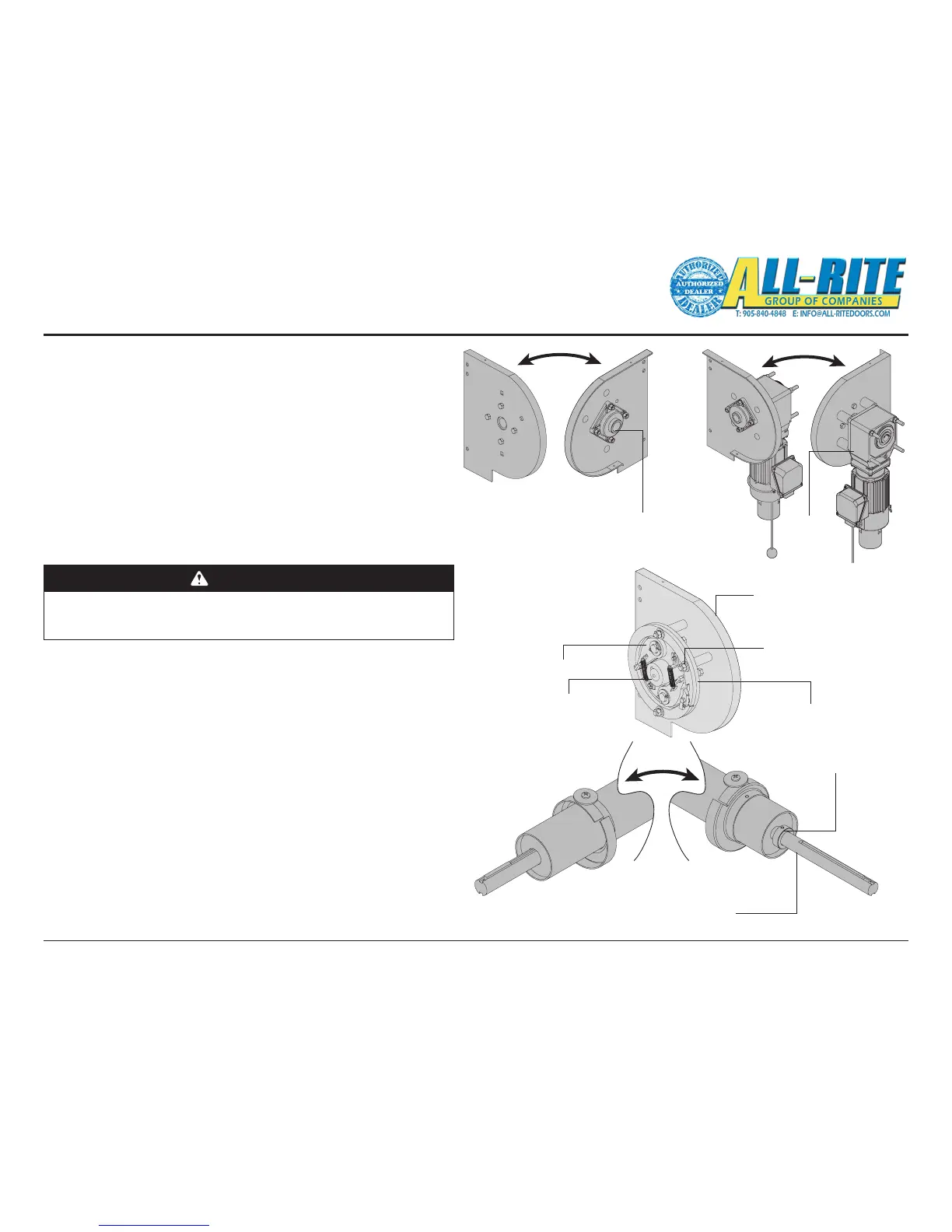

4. IDENTIFY DRIVE END OF BARREL ASSEMBLY, Fig. 4–E

Right hand drive is shown (left hand drive opposite). The drive end of

barrel assembly typically is longer and has a smaller shaft diameter

than the non-drive end.

5. MOUNT MOTOR/GEARMOTOR TO DRIVE END HEADPLATE

Attach gearmotor to drive end headplate. Drive end headplate may

come with gearmotor and motor already attached.

Installation (continued)

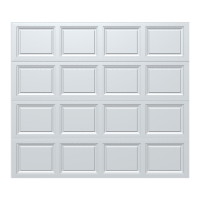

6. LOCATE SET COLLARS, SPACER COLLARS, KEYS, AND DROP STOP

DEVICE (DSD), Fig. 4-D(b) AND 4–E

in hardware box(s). Conrm drop stop device (DSD) matches the

barrel’s downward rotational direction.

A. Slide set collar, small ID (with set screw) onto drive end shaft of the

barrel assembly, Fig. 4–E. DO NOT tighten set screw at this time.

B. Slide spacer collar onto the drive end shaft of the barrel assembly.

The spacer collar separates the set collar from the headplate

bearing and has no set screws.

C. Slide set collar, 1-1/2” ID with set screw, onto non-drive end shaft of

the barrel assembly. DO NOT tighten set screw at this time.

D. Slide spacer collar onto the non-drive end shaft of the barrel

assembly. The spacer collar separates the set collar from the

headplate bearing and has no set screws.

WARNING

Perform the following installation steps 6A through 6D carefully. The

Drop Stop Device MUST BE INSTALLED to protect against rapid closure of

the door which could result in death or serious injury.

Fig 4–D(a)

Non-Drive End Headplate

Drive End Headplate

Gear

motor

Bearing

Bracket Bearing

Fig 4–D(b)

Non-Drive End

Headplate

DSD Rotor

DSD Stator

1/2” - 13 Carriage

Bolt, Lock Washer, Nut

DSD Hub

Fig 4–E

Set Collar, 1-1/4" or 1-1/2" ID,

(with 2 set screws)

Non-Drive End Drive End

Notice smaller shaft (1-1/4” or

1-1/2” ID) diameter on drive end

Loading...

Loading...