www.Wayne-Dalton.com

349981 REV2_05/17/2016

©

Copyright 2016 Wayne Dalton, a division of Overhead Door Corporation

52

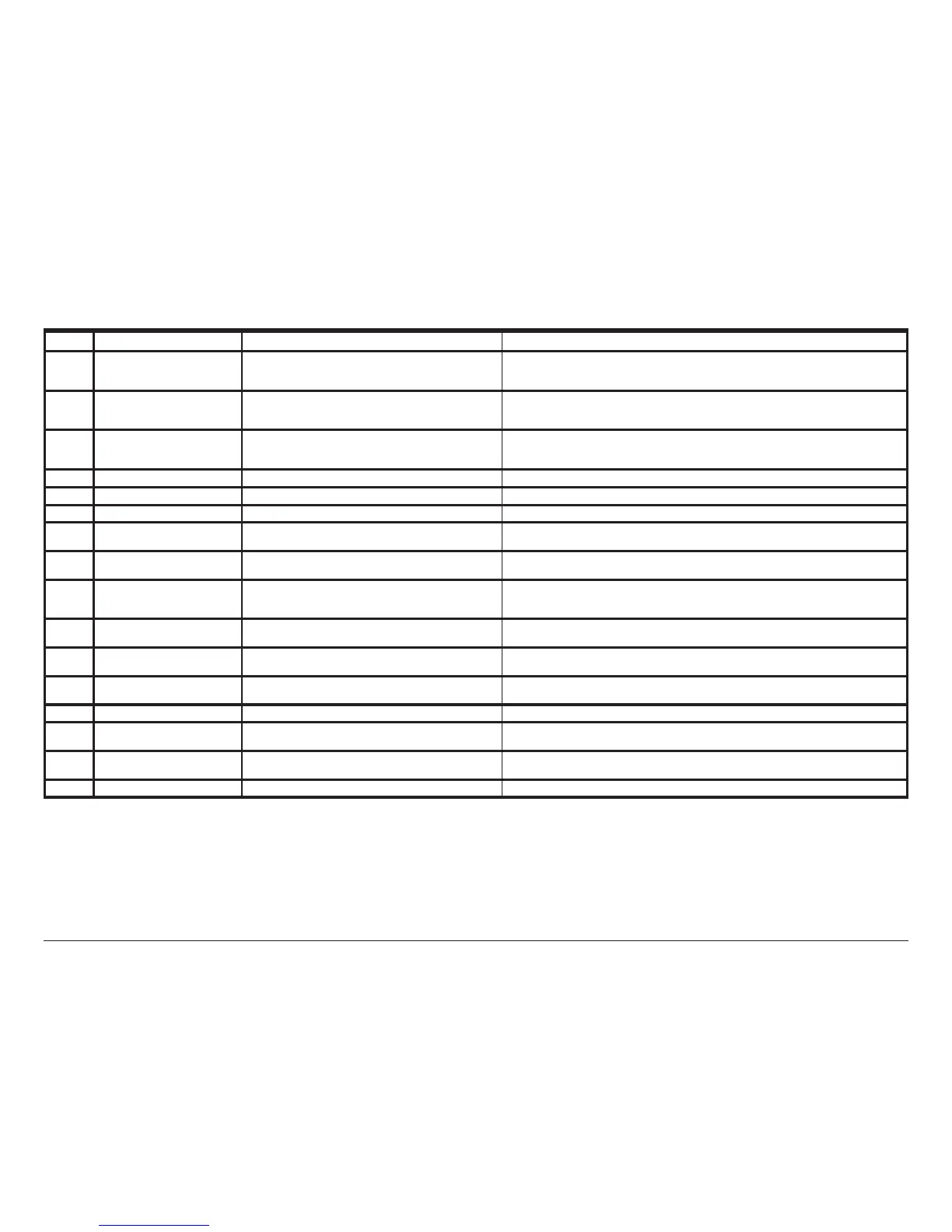

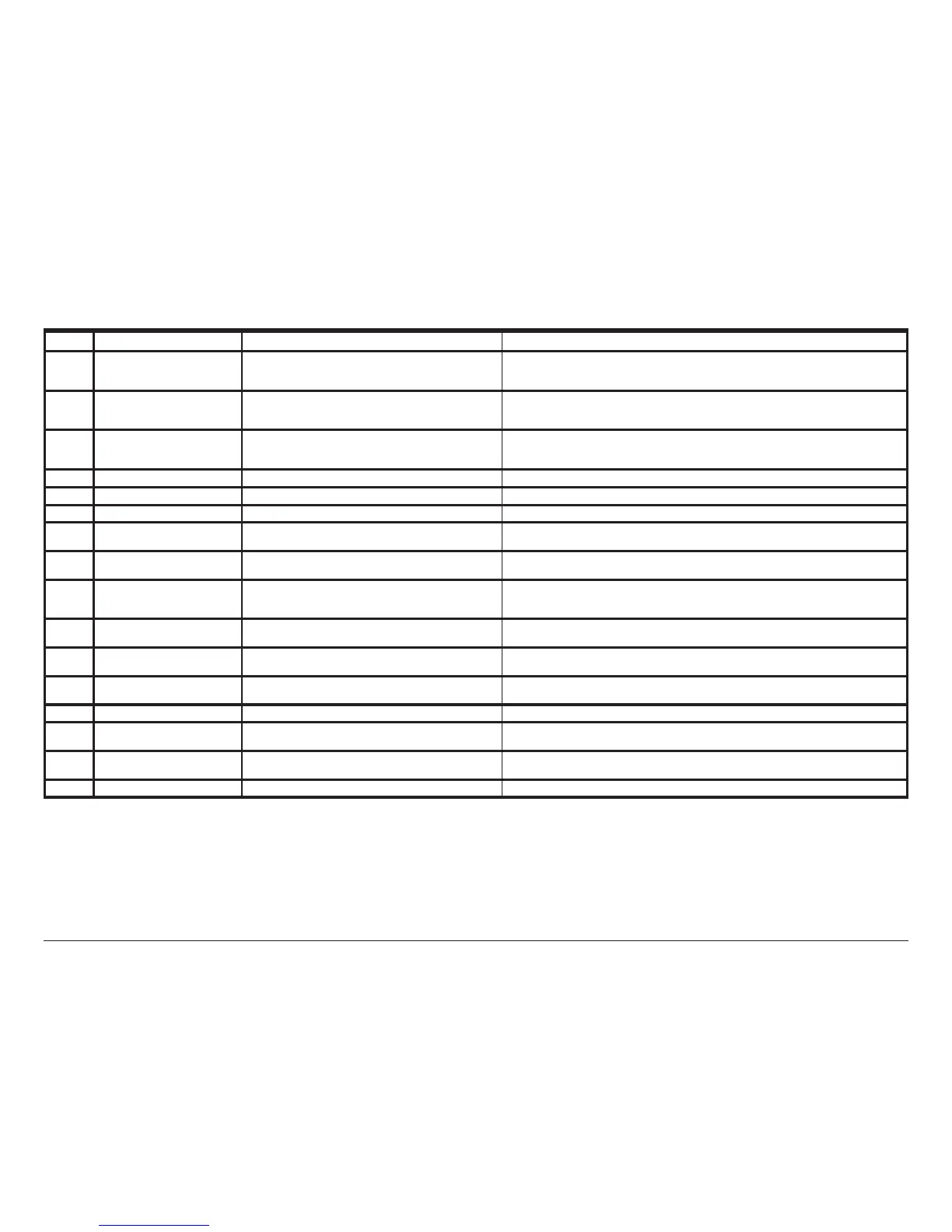

CONTROL PANEL ERROR MESSAGES DOOR CONTROL ERROR CODES

CODE DESCRIPTION PROBLEM POSSIBLE SOLUTION

E01

Slip error

(Low Priority)

Mechanical overload (Slip Monitoring) or missing signal

from encoder.

Check door for obstruction.

Ensure the pulse output from the encoder is connected to terminal P2 on the controller.

Verify that the encoder pulse output is set correctly.

E02

Direction Error - occurs during

setup only (Low Priority)

The direction of the motor is incorrect. The encoder

count must increment positively while the door is

moving in the open direction.

Use the Motor Direction parameter to set the correct direction for the motor and

encoder.

E03

No Signal From Pulse

Generator - occurs during

setup only. (Low Priority)

No pulse input detected from the encoder.

Check door for obstruction.

Ensure the pulse output from the encoder is connected to terminal P2 on the Controller.

Verify that the encoder pulse output is set correctly.

E04 Speed Error Door moves faster/slower then Expected Check door for obstruction.

E05 N/A

E06 N/A

E07

Run Timer Exceeded

(Low Priority)

The Run Timer has expired. Check the Run Timer parameter to ensure a correct value.

E08

Safety Edge Test Fail

(Medium Priority)

The Reversing Edge test has failed

Check the connections from the reversing edge to the controller. If using the Seywave

wireless system, check operation of connected host and remote door sensor.

E09

Safety Edge Connection

(Medium Priority)

The Reversing Edge connection cannot be veried.

Check the connections from the reversing edge to the controller. If using the Seywave

wireless system, check operation of connected host and remote door sensor. Verify

Safety edge is not activated.

E10

Safety Edge 1 Activated

(Low Priority)

The Reversing Edge has been activated Check for obstruction in door’s path.

E11

Safety Edge 2 Activated

(Low Priority)

The Reversing Edge has been activated Check for obstruction in door’s path.

E12

Lifting Force Exceeded

(Low Priority)

The torque limit has been exceeded

If the torque limiting feature is being used, adjust the Torque Limit parameter to suit the

application.

E13 No Encoder movement Encoder did not move when expected Check for obstruction. Check connection from Position Sensor to Motor.

E14

Absolute Encoder Comm Loss

(Top Priority)

Communication with the absolute encoder has been

lost.

Check the connections between the encoder and the controller.

E15

Installation Fault

(Low Priority)

An error occurred during Quick Setup Re-perform Quick Setup

E16 Encoder fault Encoder communication is not correct Check Position Sensor. Verify connections.

Loading...

Loading...