24 | CFW500

Installation and Connection

English

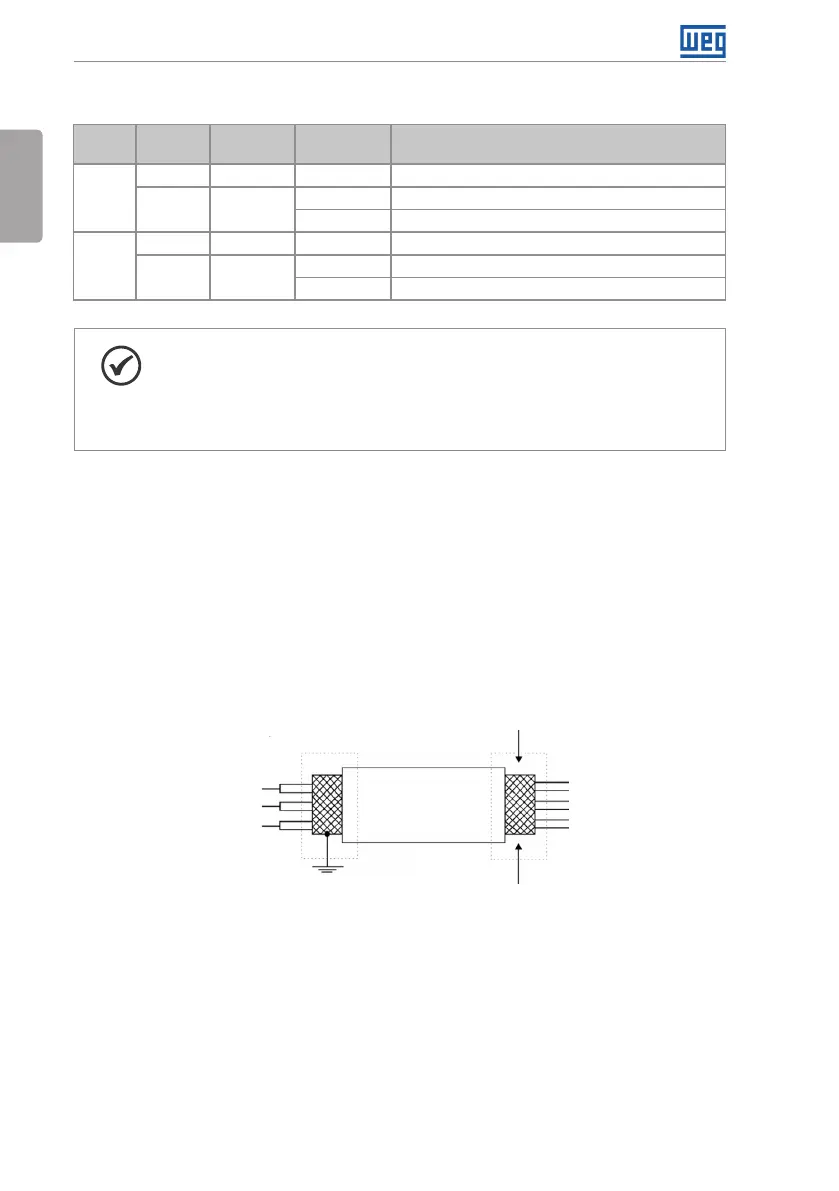

Table 3.2: Configuration of the switches to select the type of analog input and output signal on the

CFW500-IOS

Input/

Output

Signal

Setting of

Switch S1

Signal

Range

Parameter Setting

AI1

Voltage S1.1 = OFF 0...10 V P0233 = 0 (direct reference) or 2 (inverse reference)

Current S1.1 = ON

0...20 mA P0233 = 0 (direct reference) or 2 (inverse reference)

4...20 mA P0233 = 1 (direct reference) or 3 (inverse reference)

AO1

Voltage S1.2 = ON 0...10 V P0253 = 0 (direct reference) or 3 (inverse reference)

Current S1.2 = OFF

0...20 mA P0253 = 1 (direct reference) or 4 (inverse reference)

4...20 mA P0253 = 2 (direct reference) or 5 (inverse reference)

NOTE!

Configuration to connect the RS485:

S1.3 = ON and S1.4 = ON: terminal RS485 ON.

S1.3 = OFF and S1.4 = OFF: terminal RS485 OFF.

Any other combination of the switches is not allowed.

For the correct connection of the control, use:

1. Gauge of the cables: 0.5 mm² (20 AWG) to 1.5 mm² (14 AWG).

2. Maximum torque: 0.5 N.m (4.50 lbf.in).

3. Wiring of the plug-in module connector with shielded cable and separated from the other

wiring (power, command in 110 V / 220 Vac, etc), according to Item 3.2.6 Cable Separation

Distance on page 25. If those cables must cross other cables, it must be done in

perpendicularly among them, keeping the minimum separation distance of 5 cm at the

crossing point.

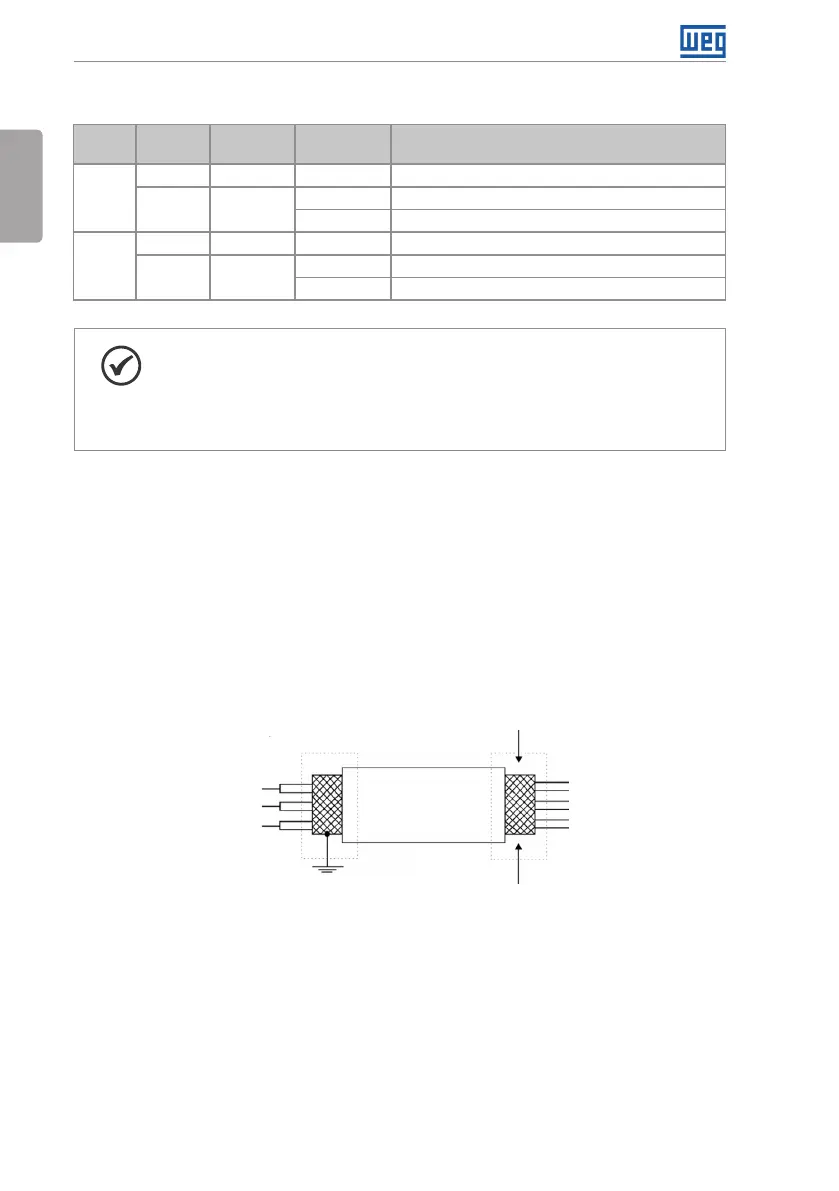

Connect the shield according to the figure below:

Do not ground

Insulate with tape

Inverter

side

Figure 3.5: Connection of the shield

4. Relays, contactors, solenoids or coils of electromechanical brake installed close to the

inverters may occasionally generate interference in the control circuitry. To eliminate this

effect, RC suppressors (with AC power supply) or freewheel diodes (with DC power supply)

must be connected in parallel to the coils of these devices.

5. When using the external HMI (refer to Section 7.2 ACCESSORIES on page 41), the cable

that connects to the inverter must be separated from the other cables in the installation,

keeping a minimum distance of 10 cm.

Loading...

Loading...