14 | CFW500

Installation and Connection

English

Allow the minimum clearances indicated in Figure B.3 on page 172, in order to allow the cooling

air circulation. Do not install heat sensitive components right above the inverter.

ATTENTION!

When installing two or more inverters vertically, respect the minimum

clearance A + B (as per Figure B.3 on page 172) and provide an air deflecting

plate so that the heat rising up from the bottom inverter does not affect the

top inverter.

Provide independent conduits for the physical separation of signal, control,

and power cables (refer to the Section 3.2 ELECTRICAL INSTALLATION on

page 15).

3.1.2.1 Cabinet Mounting

For inverters installed inside cabinets or metallic boxes, provide proper exhaustion, so that the

temperature remains within the allowed range. Refer to the dissipated powers in Table B.4 on

page 162 and Table B.5 on page 164.

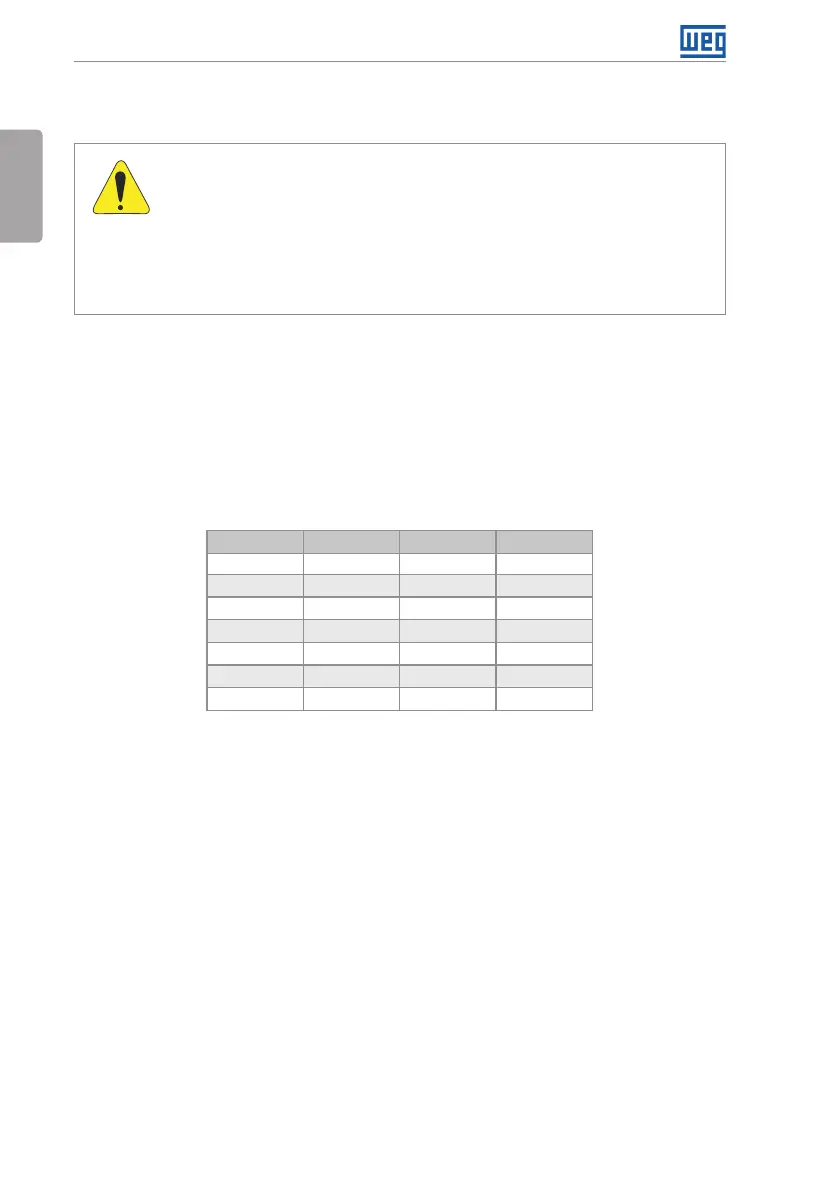

As a reference, Table 3.1 on page 14 shows the air flow of nominal ventilation for each frame size.

Cooling Method: fan with air flow upwards.

Table 3.1: Air flow of the fan

Frame Size CFM I/s m

3

/min

A 20 9.4 0.56

B 30 14.1 0.85

C 30 14.1 0.85

D (T2)

(*)

100 47.2 2.83

D (T4)

(**)

80 37.8 2.27

E 180 84.5 5.09

F 214 100.4 6.05

(*) T2 - CFW500 frame size D line 200 V (200...240 V).

(**) T4 - CFW500 frame size D line 400 V (380...480 V).

3.1.2.2 Surface Mounting

Figure B.3 on page 172 illustrates the procedure for the installation of the CFW500 on the

mounting surface.

3.1.2.3 DIN-Rail Mounting

In frame sizes A, B and C, the inverter CFW500 can also be mounted directly on 35-mm rail as

per DIN EN 50.022. For this mounting, you must first position the lock

(*)

down and then place

the inverter on the rail, position the lock

(*)

up, fixing the inverter.

(*) The fastening lock of the inverter on the rail is indicated with a screwdriver in Figure B.3 on page 172.

3.1.2.4 Flange mounting

In frame size F, the inverter CFW500 can also be mounted in flange. For this mounting, remove

the drive mounting brackets for flange mounting. The protection degree of the inverter outside the

panel is IP55 for flange mounting. It is necessary to provide proper seal for the opening where the

inverter is installed to ensure the protection degree of the panel. Example: sealing with silicone.

Please refer to Figure B.3 on page 172 for flange mounting data.

Loading...

Loading...