English

TROUBLESHOOTINGANDMAINTENANCE

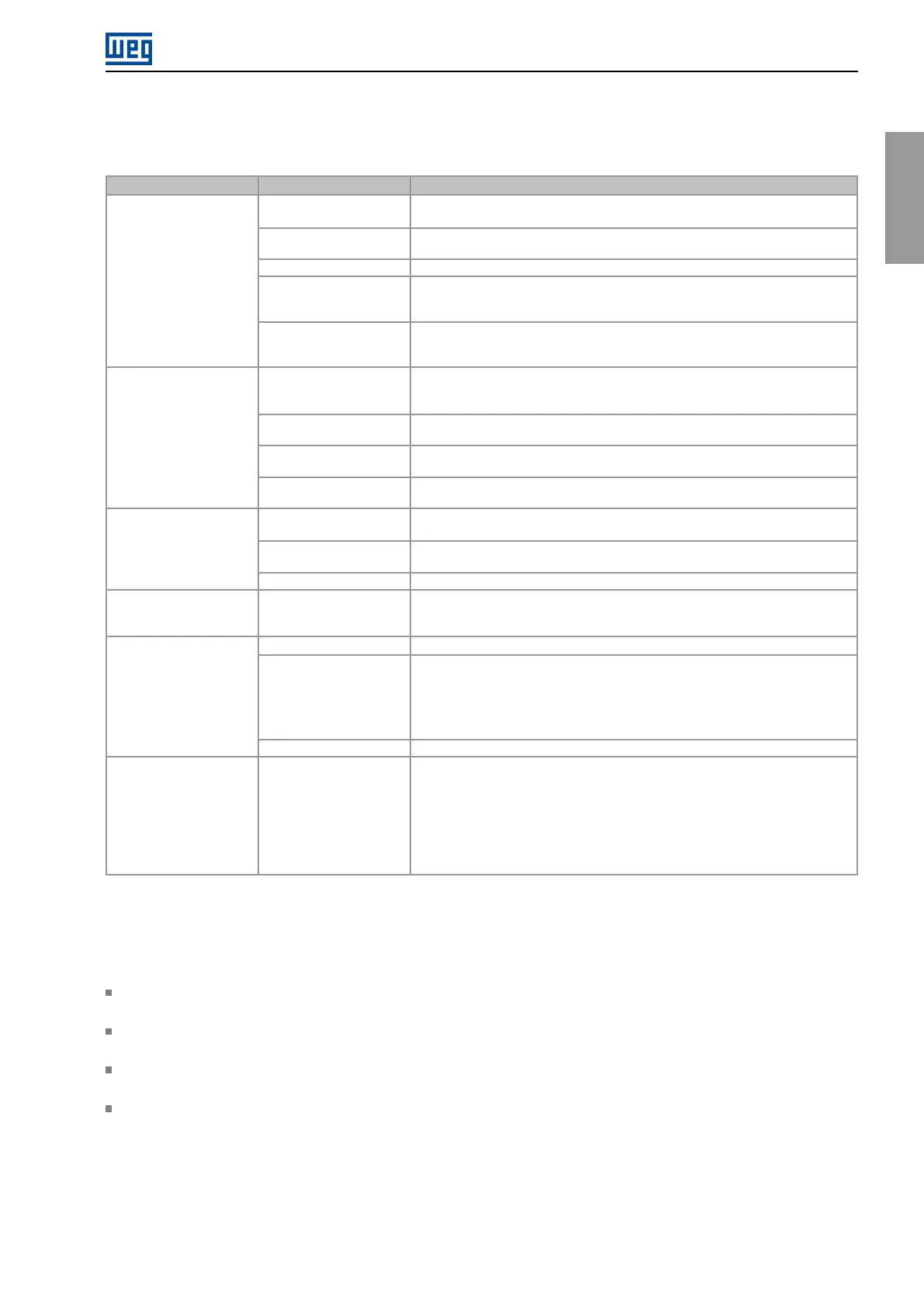

6.4SOLUTIONSFORTHEMOSTFREQUENTPROBLEMS

Table6.2:Solutionsforthemostfrequentproblems

ProblemPointtobeverifiedCorrectiveAction

MotordoesnotstartIncorrectwiring

connection

1.Checkallpowerandcontrolconnections.Forinstance,thedigitalinputsset

toStart/Stop,GeneralEnable,ornoexternalerrorshallbeactivated

Analogreference(ifused)1.Checkiftheexternalsignalisproperlyconnected

2.Checkthestatusofthecontrolpotentiometer(ifused)

Incorrectsettings1.Checkifparametersareproperlysetfortheapplication

Fault1.Checkiftheinverterisnotblockedduetoafaultcondition

2.Checkifthereisashortcircuitbetweentheterminalsofthe24Vdcpower

supply

Motorstall1.Decreasemotoroverload

IncreaseC3.2.1.1(V/F)or

C3.3.5.1.2,C3.3.5.1.3,C3.3.5.1.4andC3.3.5.1.5(vectorcontrol)

Motorspeedfluctuates

(oscillates)

Looseconnection1.Stoptheinverter,turnoffthepowersupply,andcheckandtightenallpower

connections

2.Checkallinternalconnectionsoftheinverter

Defectivereference

potentiometer

1.Replacepotentiometer

Oscillationoftheexternal

analogreference

1.Identifythecauseoftheoscillation.Ifitiscausedbyelectricalnoise,use

shieldedcablesorseparatefromthepowerandcontrolwiring

Incorrectsettings(vector

control)

1.CheckparametersC2.2.2andC2.2.4

2.Refertotheprogrammingmanual

Motorspeedtoohighor

toolow

Incorrectsettings

(referencelimits)

1.CheckifthecontentofC4.3.1.1.1(minimumspeed)andC4.3.1.1.2(maximum

speed)areaccordingtothemotorandapplication

Control signalfrom the

analogreference(ifused)

1.Checkthelevelofthereferencecontrolsignal

2.Checktheprogramminggainsandoffset

Motornameplate1.Checkifthemotorhasbeenproperlysizedfortheapplication

Motordoesnotoperate

inthefieldweakening

region(VectorControl)

Settings1.CheckC2.2.2e C3.3.7.1

OffdisplayKeypadconnections1.Checktheinverterkeypadconnection

Powersupplyvoltage1.Ratedvaluesshallbewithinthelimitsspecifiedbelow:

200-240Vcapowersupply:-Min:187Vca

-Max:253Vca

380-480Vcapowersupply:-Min:323Vca

-Max:528Vca

Blownfuses1.Replacefuses

Lowmotorspeedand

S1.1.4=C3.3.5.1.2

ouC3.3.5.1.3

ouC3.3.5.1.4ou

C3.3.5.1.5(motorin

torquelimitation),for

C3.1.1=2(vectorwith

encoder)

Encodersignalsare

invertedorpower

connectionisinverted

1.CheckifthesignalsA,

¯

A ,B,

¯

B arecorrectlyconnectedtotheCFW900-

IOS

(item3.2.6)ortotheaccessoryofinputsforincrementalencoder(seethe

CFW900-ENC-01manual).Ifsignalsareproperlyinstalled,exchangetwoofthe

outputphases.ForinstanceUandV.

6.5INFORMATIONFORCONTACTINGTECHNICALSUPPORT

Fortechnicalsupportandservicing,itisimportanttohavethefollowinginformationinhand:

Invertermodel.

Productserialnumberandmanufacturingdatecontainedintheidentificationlabel(seeSection2.3.1).

Installedsoftwareversion(seeparameterS1.2.1).

Applicationdataandinvertersettings.

CFW900|89

Loading...

Loading...