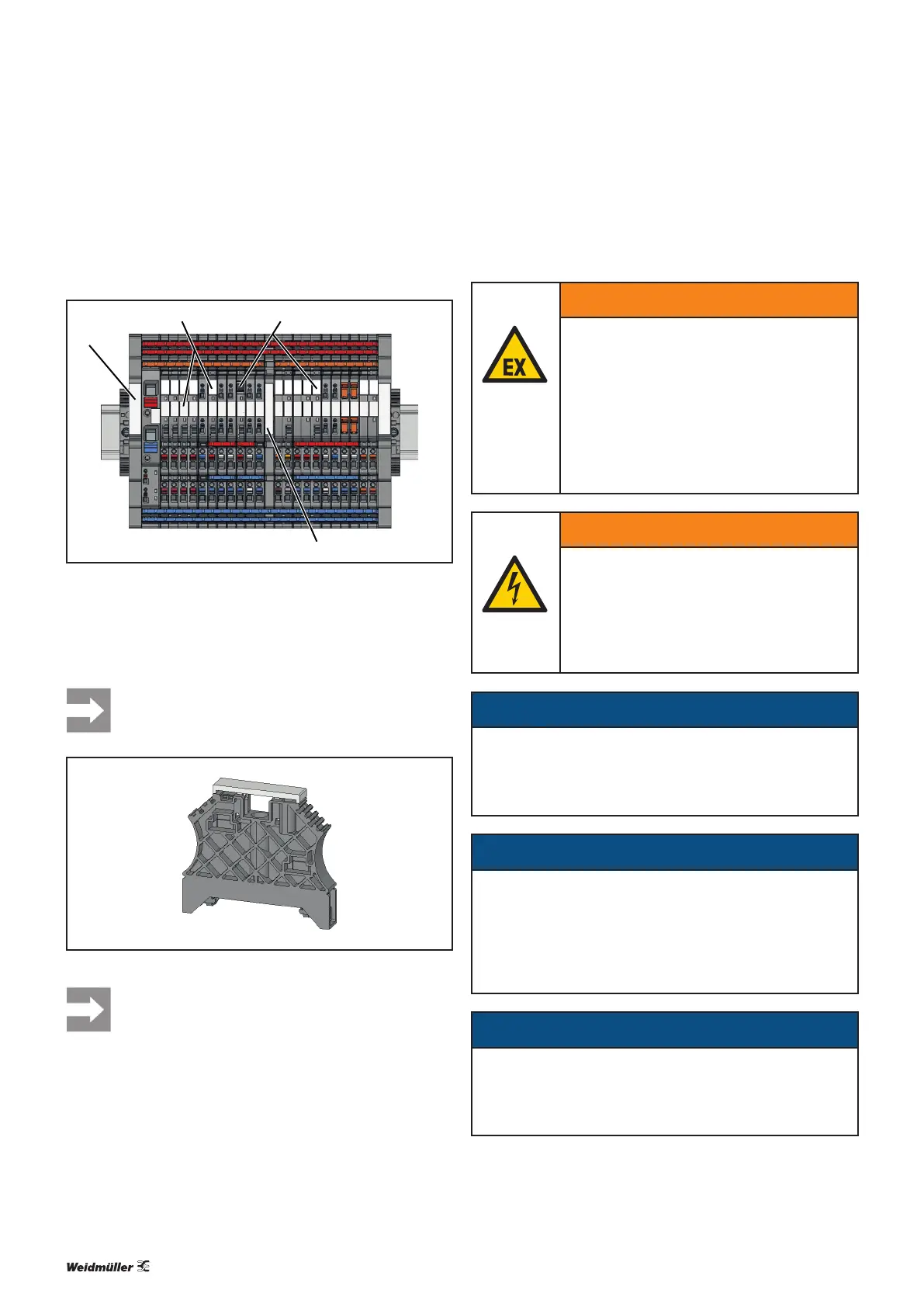

8.3 Attaching markers

1

1

2 3

4

Installing an end bracket

1 WAD8 group marker or EM8/30 end bracket marker

2 WS terminal marker for 6mm pitch (WS10/6 or WS 8/6)

3 WS terminal marker for 6mm pitch (WS10/6 or WS 8/6)

4 WAD5 group marker

We recommend tting the thumbwheel switch of

adjustable load monitors with a terminal marker

displaying the adjusted value.

Fitting a marker on an end bracket

The WEW 35/2 end brackets can only be tted

with a marker if they are not installed together

with an end plate.

8.4 Installing cross-connectors

WARNING

Explosion risk!

▶ Before starting any work, make sure that

there is not a potentially explosive atmos-

phere!

▶ For applications in explosive risk zones,

observe the installation and construction

requirements of EN60079-15 and/or

country-specific regulations.

WARNING

Dangerous contact voltage!

▶ Carry out installation and wiring work on

the maxGUARD station only when the

power supply is disconnected.

▶ Make sure that the place of installation

(panel etc.) has been disconnected from

the power supply!

ATTENTION

Risk of short circuit due to non-insulated cross-

connectors!

▶ Insert an AMGPP separation plate wherever there are

bare cut edges next to one another.

ATTENTION

Risk of malfunction!

▶ Do not connect multiple load monitors in parallel or in

series.

▶ Never connect the signal contacts of the control and

alarm modules to the outputs of the load monitors.

ATTENTION

The product can be destroyed!

If the total current is over 20A, all main strands must each

be equipped with two cross-connectors.

Once the maxGUARD station has been mechanically in-

stalled, the cross-connectors can be tted in accordance with

the installation drawing or wiring diagram.

50Manual maxGUARD2526740000/02/03.2018

8 Installationandwiring | Attaching markers

Loading...

Loading...