上海维宏电子科技股份有限公司

SHANGHAI WEIHONG ELECTRONIC TECHNOLOGY CO., LTD.

49 / 61

2. Double-click the target PhysicalAddress field to specify a physical address

(controller and port) for the corresponding logical address.

8.3.5 Configure Dual Drive

Follow the steps below to configure dual drive axis:

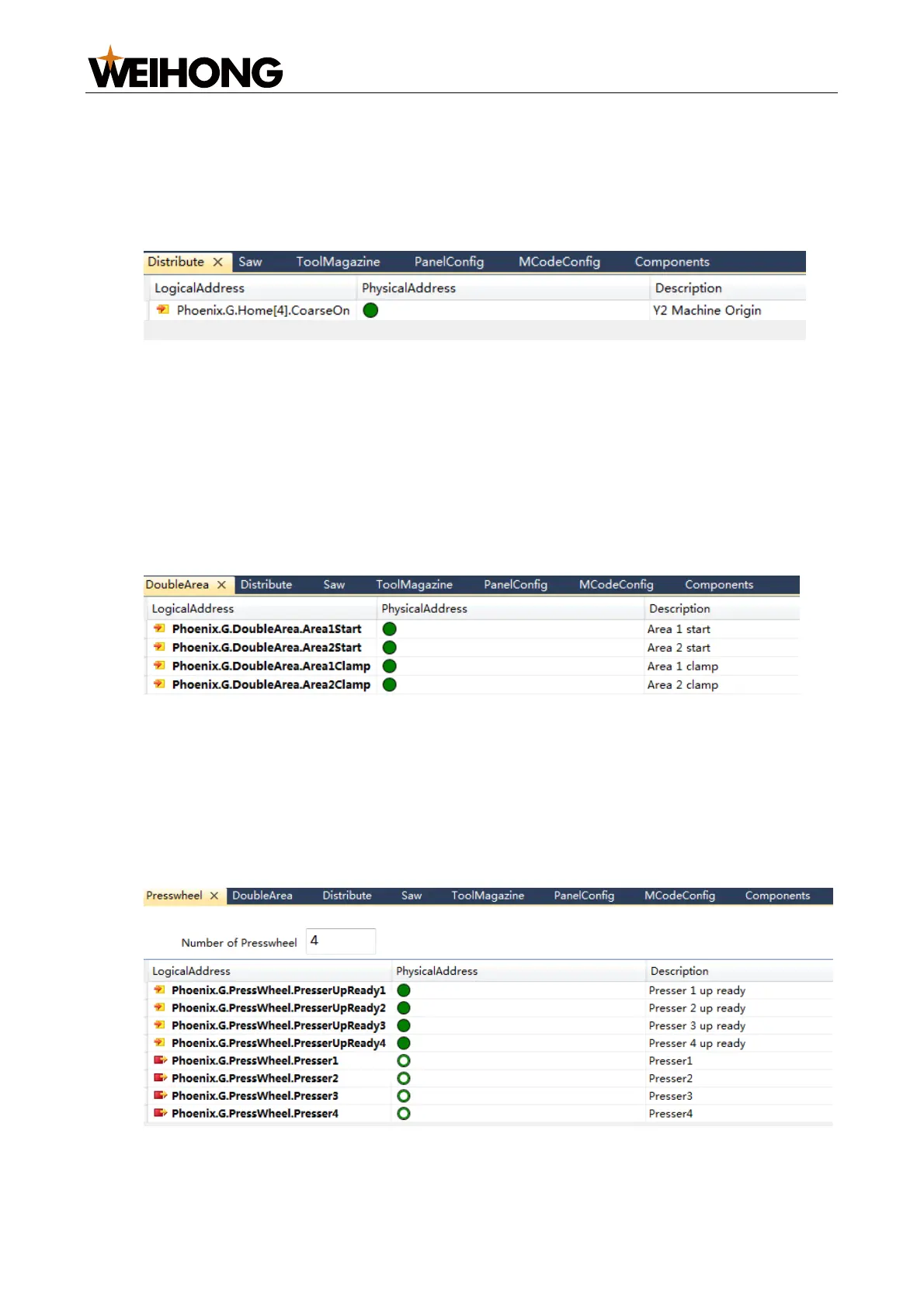

1. In the left Configuration list, double-click Distribute to open the Distribute page

on the right:

2. Double-click the target PhysicalAddress field to specify a physical address

(controller and port) for the corresponding logical address.

8.3.6 Configure Dual Work Stations

If dual work stations are enabled, the system directly starts machining on work station 2

after machining on work station 1 is finished to save loading and unloading time and

improve efficiency.

Follow the steps below to configure dual work stations:

1. In the left Configuration list, double-click DoubleArea to open the DoubleArea

page on the right:

2. Double-click the target PhysicalAddress field to specify a physical address

(controller and port) for the corresponding logical address.

8.3.7 Configure Press Wheel

Press wheels can be used to prevent plates from moving when being processed.

Follow the steps below to configure press wheels:

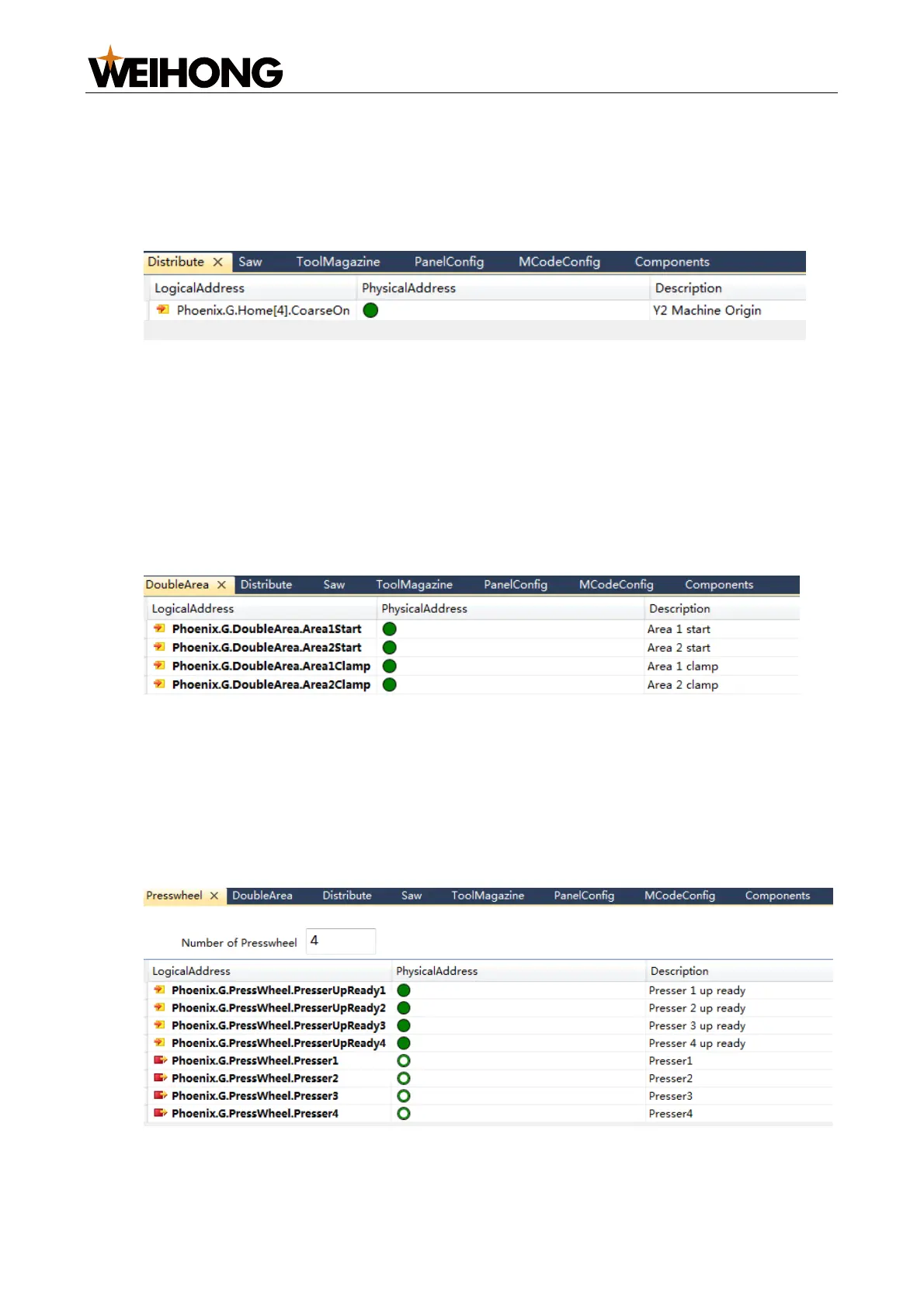

1. In the left Configuration list, double-click PressWheel to open the PressWheel

page on the right:

2. Set the parameter Number of Presswheel.

Loading...

Loading...