OxiTop

®

Control OC 100 What to do if...

ba31114e06 06/2012 73

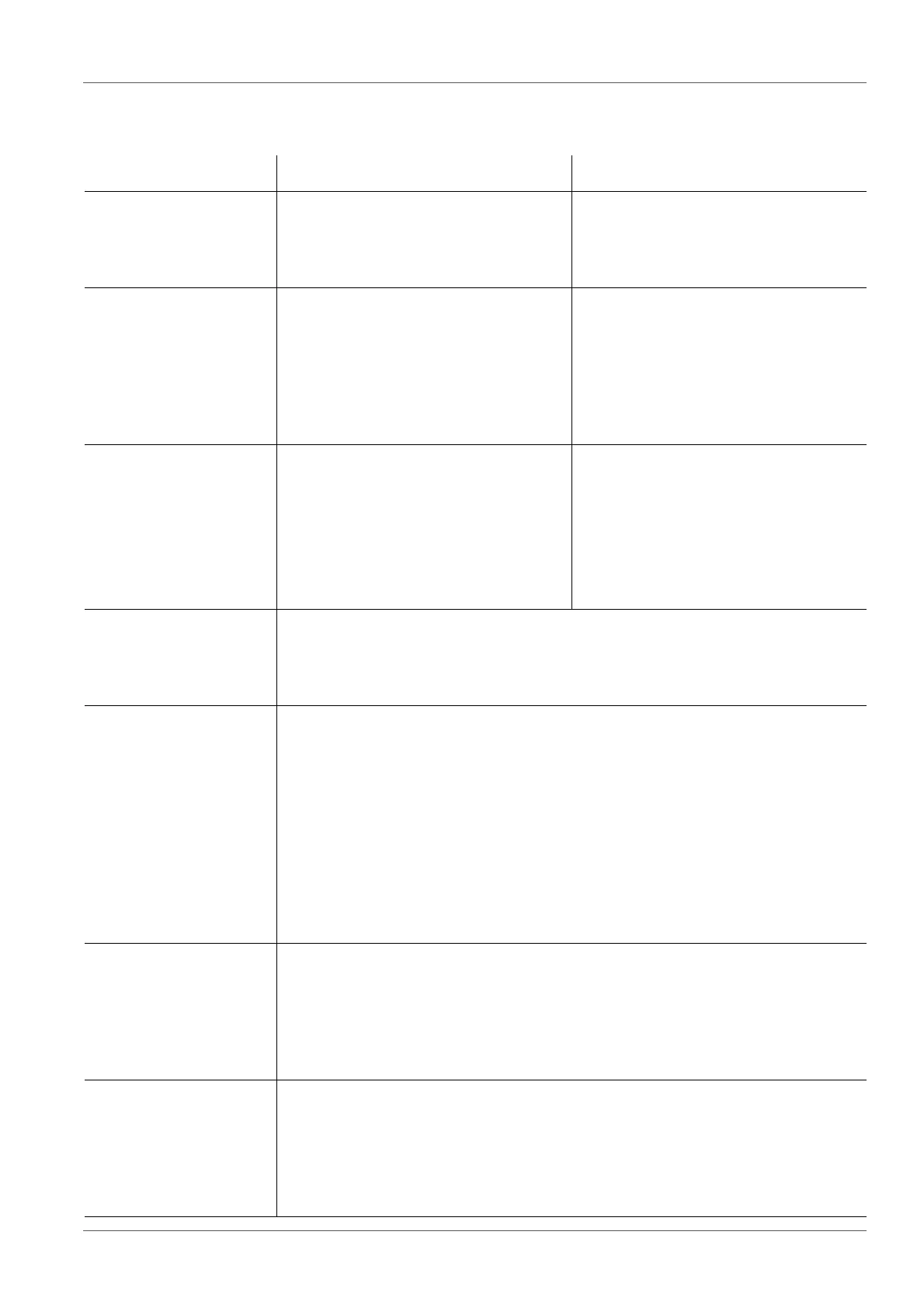

10.3 General information

Cause Remedy

No or missing sample

entries in the sample

management

The BOD Routine operating mode

is switched on. Samples were

started in the other operating

modes.

Switch on the BOD Standard oper-

ating mode

(see section 7.4.1 O

PERATING

MODE, page 40).

At the beginning of the

measurement, no

measurement curves

are displayed

Measurement curves

do not emerge from

the origin

The sample filled and started was

too cold.

The AutoTemp function is switched

off.

Temper the sample more precisely.

Switch on the AutoTemp function

(only effective with run durations of

more than 1 day).

No measurement

curves are displayed

although the measure-

ment has already been

running for an extended

period of time

No data were retrieved from the

measuring heads.

The AutoTemp phase is still run-

ning (see section 7.4.7 A

UTOTEMP,

page 44).

Call up the data of the measuring

heads.

See section 5.3 C

ALLING UP ALL

DATA, page 22.

Wait for the end of the AutoTemp

phase then start the

evaluation.

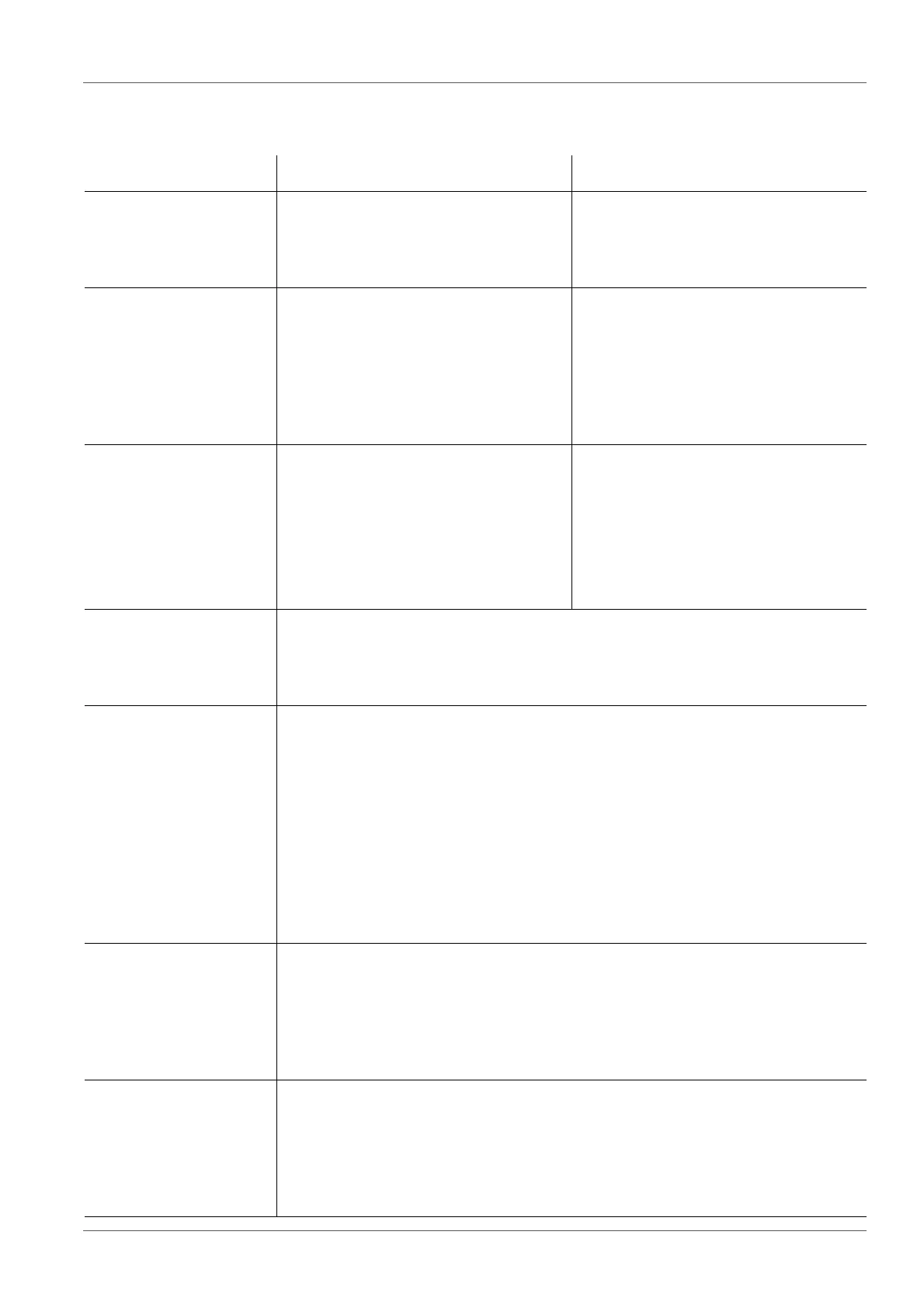

Search for free

measuring heads for a

new measurement

Perform the - Show free function (see section 7 GLP/TOOLS, page

38).

The controller causes the free measuring positions to flash

for 5 seconds.

Measuring head

unintentionally started

for measurement

Measuring head

started with incorrect

settings

Measuring head is

required for another

sample

The measuring head can be released again through the

command Reset/release:

see section 7.6.2 R

ESET/RELEASE, page 56.

The controller guides you further through the operation.

If only one measuring head is stored under the corresponding sample number

(in the BOD Routine operating modes, this is always the case), the controller

automatically erases the sample in the sample management.

Search for a defective

measuring head

Perform a measuring head reaction test (see above). A measuring head that

repetitively shows no reaction to the test is defective.

If the defective measuring head cannot be established in this way, perform the

measuring head check (see “Single check”). In doing this, each individual

measuring head must be checked until the defective measuring head has

been found.

A measuring head is

missing or is defective.

Requirement:

To determine the

corresponding sample

Call up the function “Call up data” from the sample

management for each individual unfinished sample. The corresponding sam-

ple can be determined by this.

For subsequent error handling, see section 5.4.4 C

ALLING UP DATA, page 27.

Loading...

Loading...