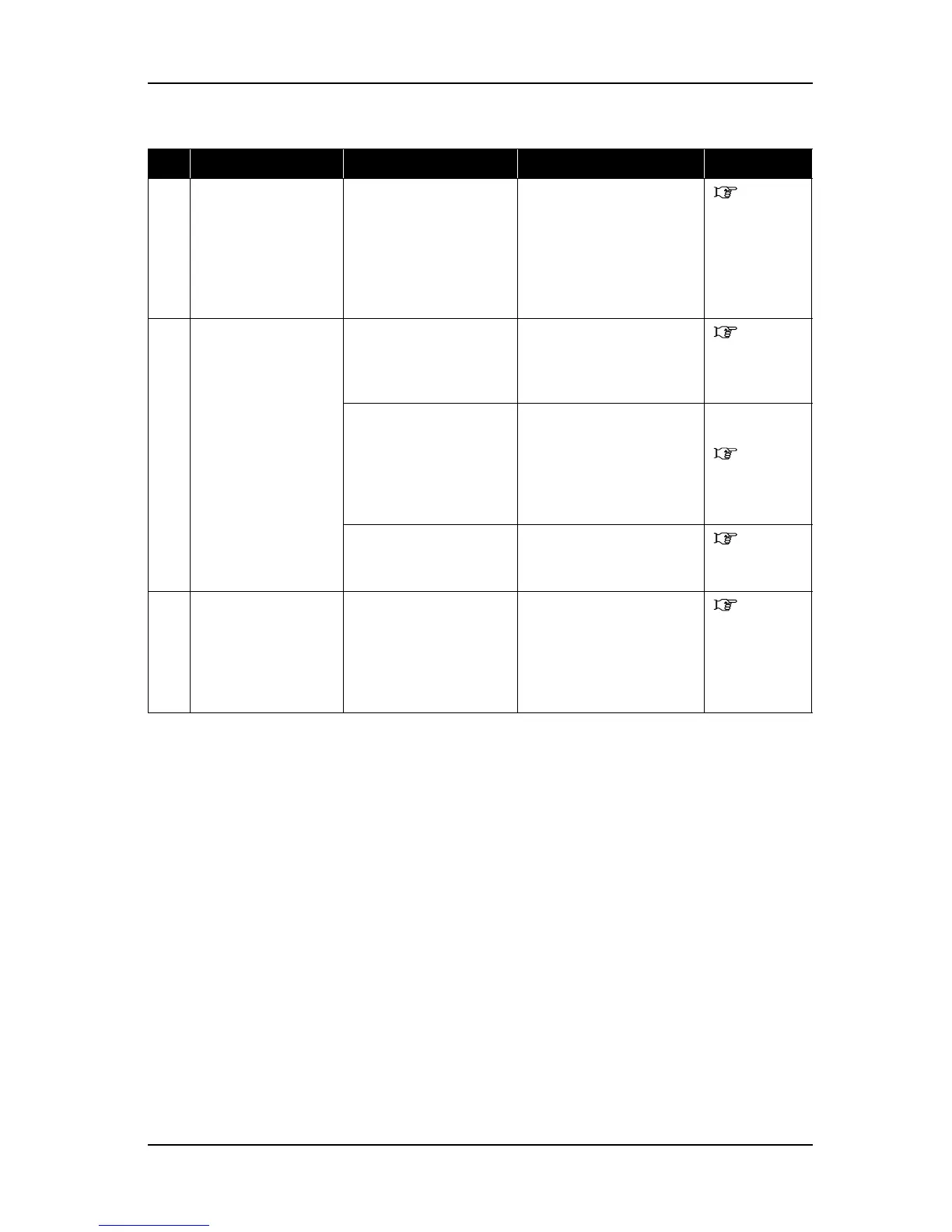

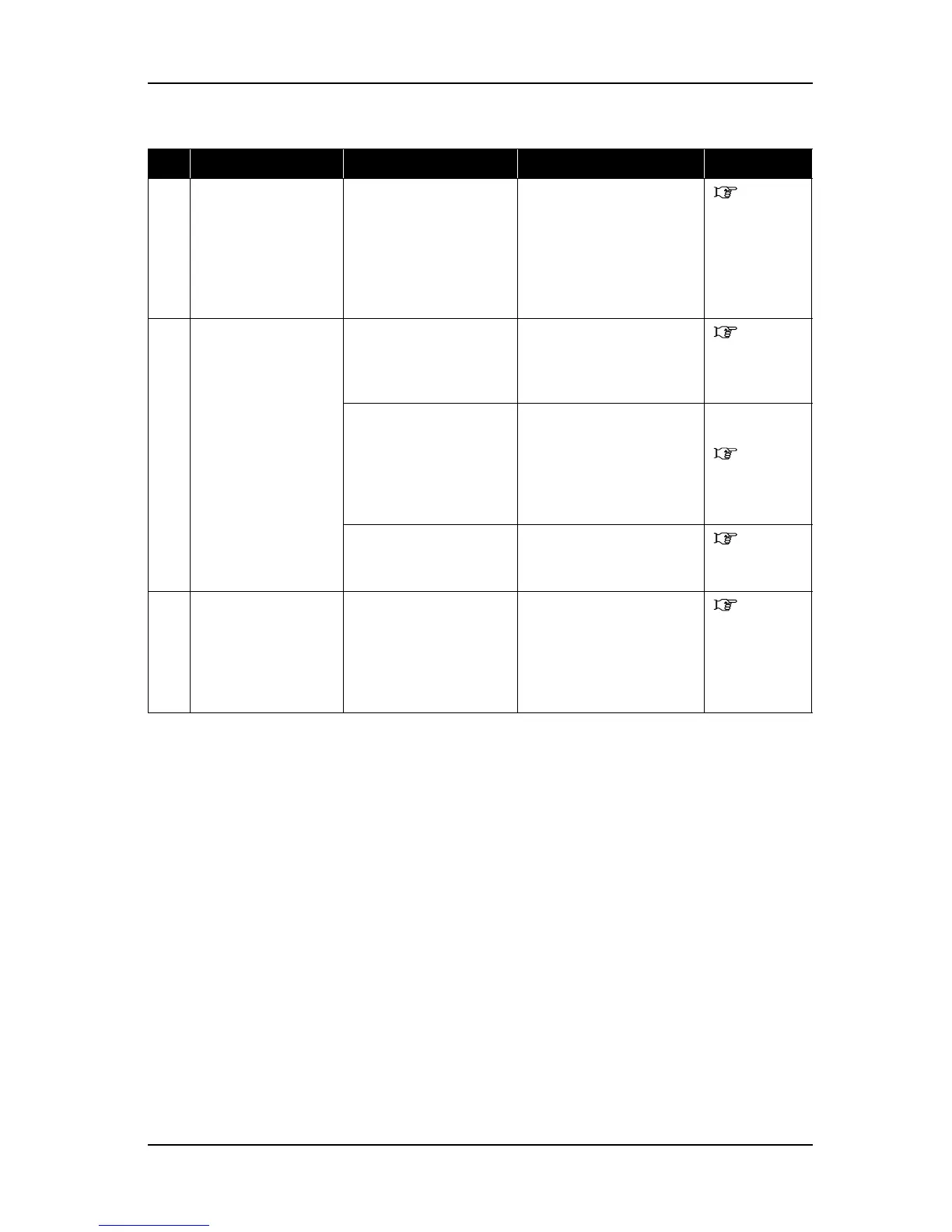

RJ-901C/RJ-900C Maintenance Manual 9 Troubleshooting

9-43

4 Media jams during

media set

initialization or

printing.

1. When pressure lever

is moved backward

and forward, does

pressure assembly

move smoothly in

synchronization with

it?

Lubricate pressure cam. "8.4

Lubrication/

Bonding"

p.8-6

5 Media is torn during

media set

initialization or

printing.

1. Does pressure roller

drag when pressure

lever is raised?

If pressure roller collects

media dust on itself, wipe

dust away using a wet soft

cloth.

Operation

Manual

2. Does media guide

have large distortion

or foreign objects?

• If media guide collects

media dust or other

foreign objects on it,

remove them.

• Replace media guide.

"4.2.7

Removing

Media Guide

R2" p.4-14

3. When using roll

media, are flanges

attached correctly?

Insert flanges correctly into

core pipe of media roll.

Operation

Manual

6 Machine registers

wrong media size

after media set

initialization.

1. Is media in use a

recommended one?

Set recommended media

and check printout again.

With non-authorized

media, media sensor may

fail to detect media

correctly.

Operation

Manual

Table 9-10 Symptoms, Check Items and Actions for Media Feed Problems(Continued)

No. Symptom Check item Action Reference

Loading...

Loading...