188

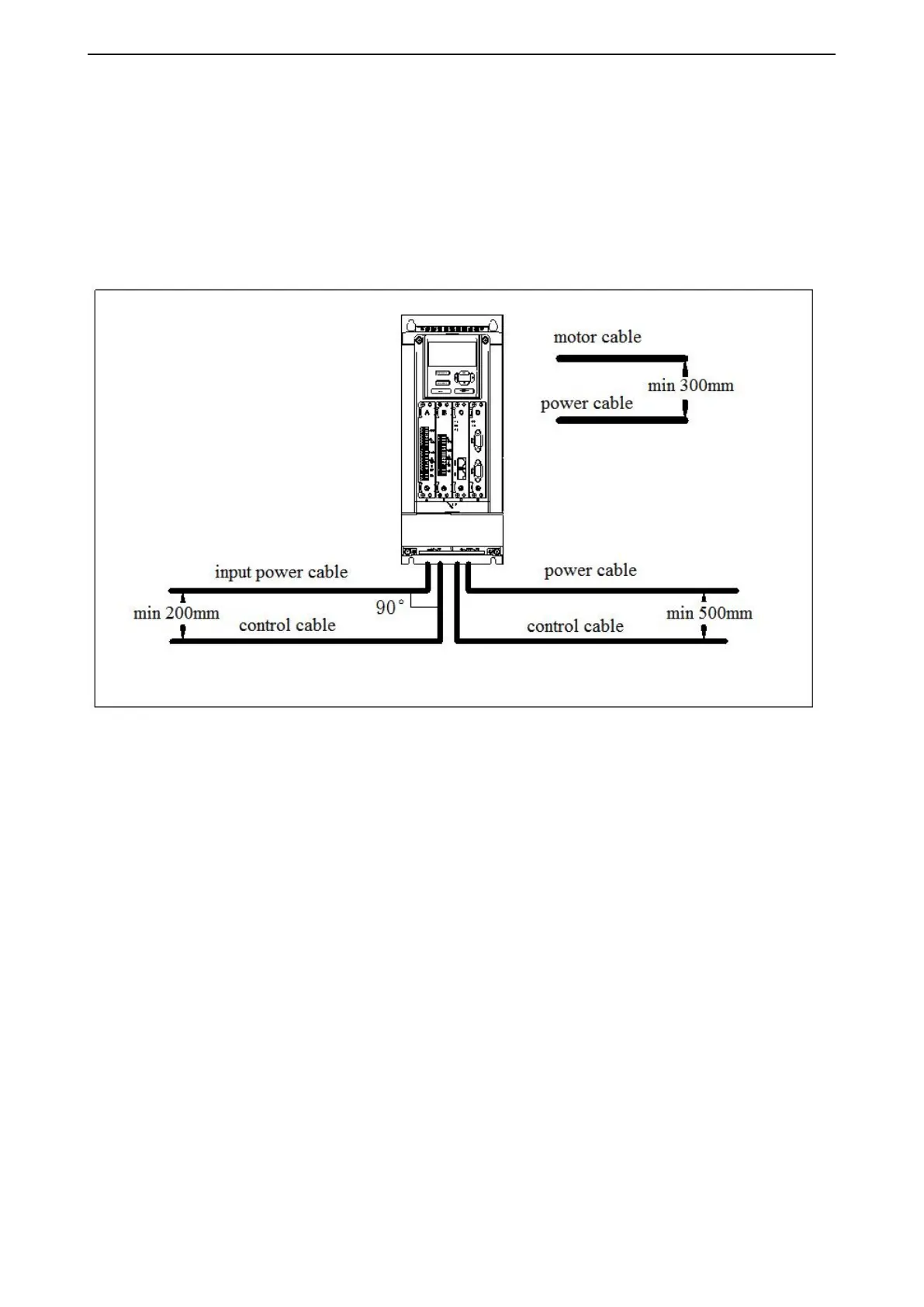

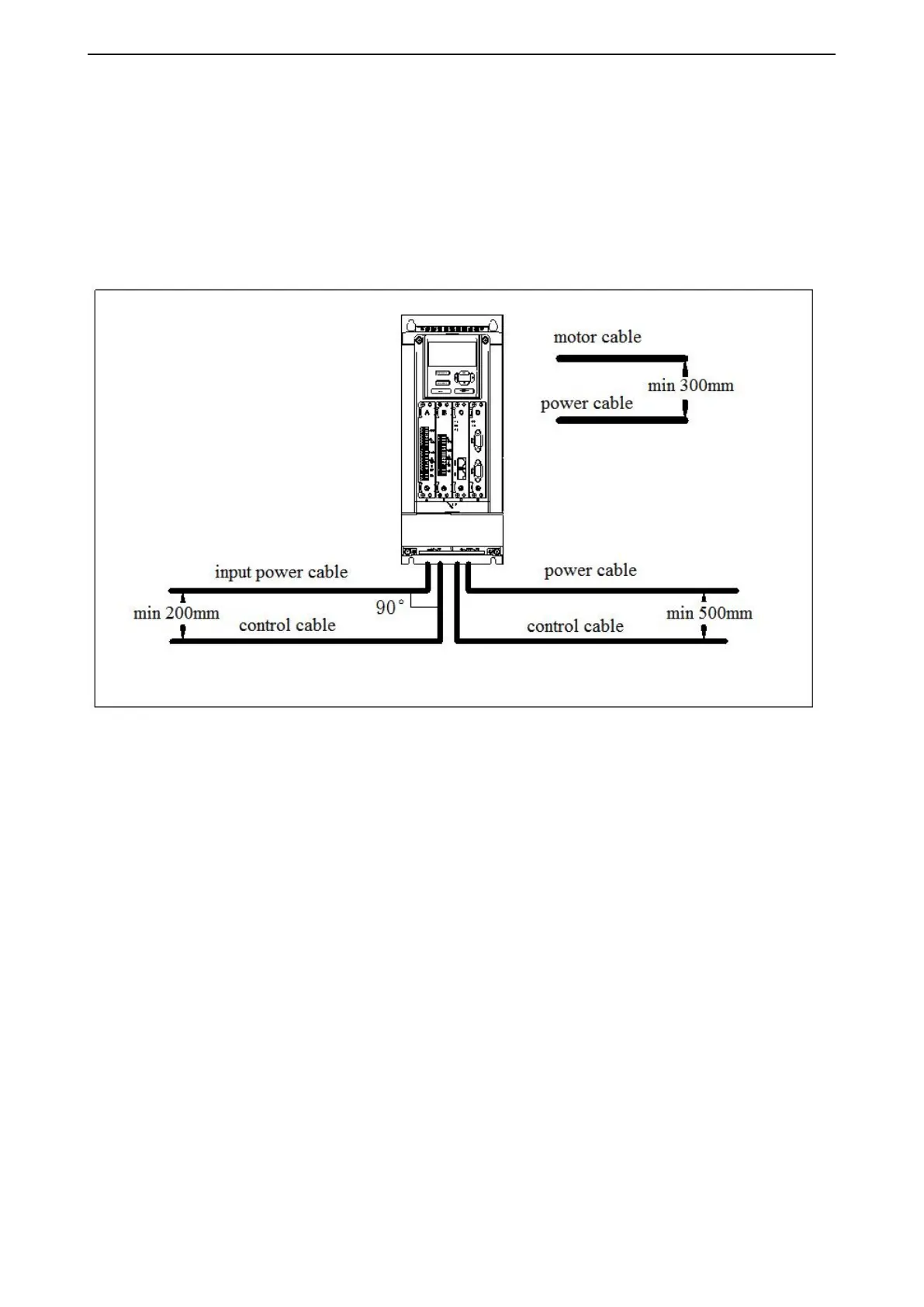

inverters can be run side by side. It is suggested that the motor cable, input power cable and control cable

should be distributed in different trunking. The reason to avoid the side-by-side routing of other cables and

motor cables is that the du/dt output from the inverter will increase the electromagnetic interference to other

cables.

If the control cable and the power cable must be crossed, the angle between the control cable and the power

cable must be 90 degrees.

The cable trunking must be well connected and well grounded. Aluminum trunking can make local

equipotential.

Insulation inspection

Before operation, please check the insulation of motor and motor cable

(1) Make sure that the motor cable is connected to the motor, and then remove the motor from the output

terminal UVW of the inverter.

(2) Use a 500VDC megger to measure the insulation resistance between each phase conductor and the

protective grounding conductor. For the insulation resistance of the motor, please refer to the motor

manufacturer's instructions.

(3) If the inside of the motor is wet, the insulation resistance will decrease. If moisture is suspected, dry the

motor and measure again.

6-3-3. Selection guidance of circuit breaker, contactor and fuse

In order to prevent the overload from damaging the inverter, it is necessary to add a fuse at the incoming

end.

A manually operated power short circuit device (MCCB) needs to be installed between AC power supply

and frequency converter. The circuit breaker equipment must be able to be locked in the cut off position to

facilitate installation and maintenance. The capacity of the circuit breaker is generally 1.5-2 times of the

rated current of the inverter.

In order to effectively cut off the input power of frequency converter in case of system failure, AC

Loading...

Loading...