91

4-2. Parameter explanation

4-2-1. Group P0 Basic operation parameter

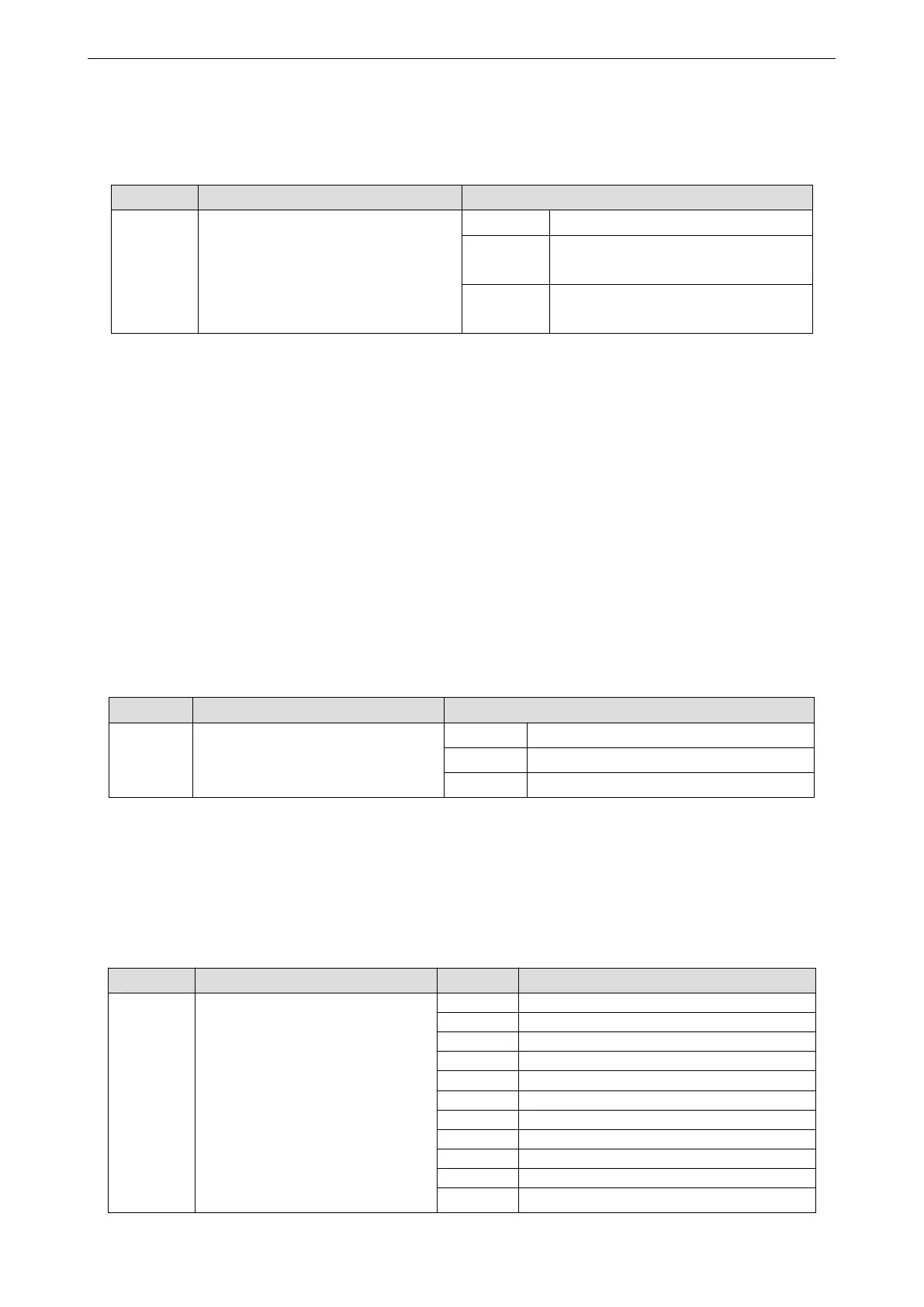

First motor control mode selection

No speed sensor vector control

(SVC)

With speed sensor vector control

(FVC)

0: VF control

VF control is suitable for low-speed occasions where the control accuracy is not high, and can also be used for

occasions where one inverter drives multiple motors. It is recommended to set P1-00 ~ P1-05 in VF control.

1: No speed sensor vector control (SVC)

It refers to the open-loop vector control, which can be applied to high-performance general occasions without

pulse encoder, occasions requiring low-frequency large torque and high speed control accuracy, such as

machine tools, centrifuges, wire drawing machines, injection molding machines, etc.

2: With speed sensor vector control (FVC)

It refers to closed-loop vector control. The motor end must be equipped with encoder, and the frequency

converter must be equipped with PG card of the same type as the encoder. Suitable for high precision speed

control or torque control occasions, such as high-speed paper machinery, lifting machinery, elevators and other

loads.

For vector control of frequency converter, only one motor can be driven by one frequency converter, so accurate

parameters of controlled motor must be obtained for self tuning. See P1-35 for specific tuning method.

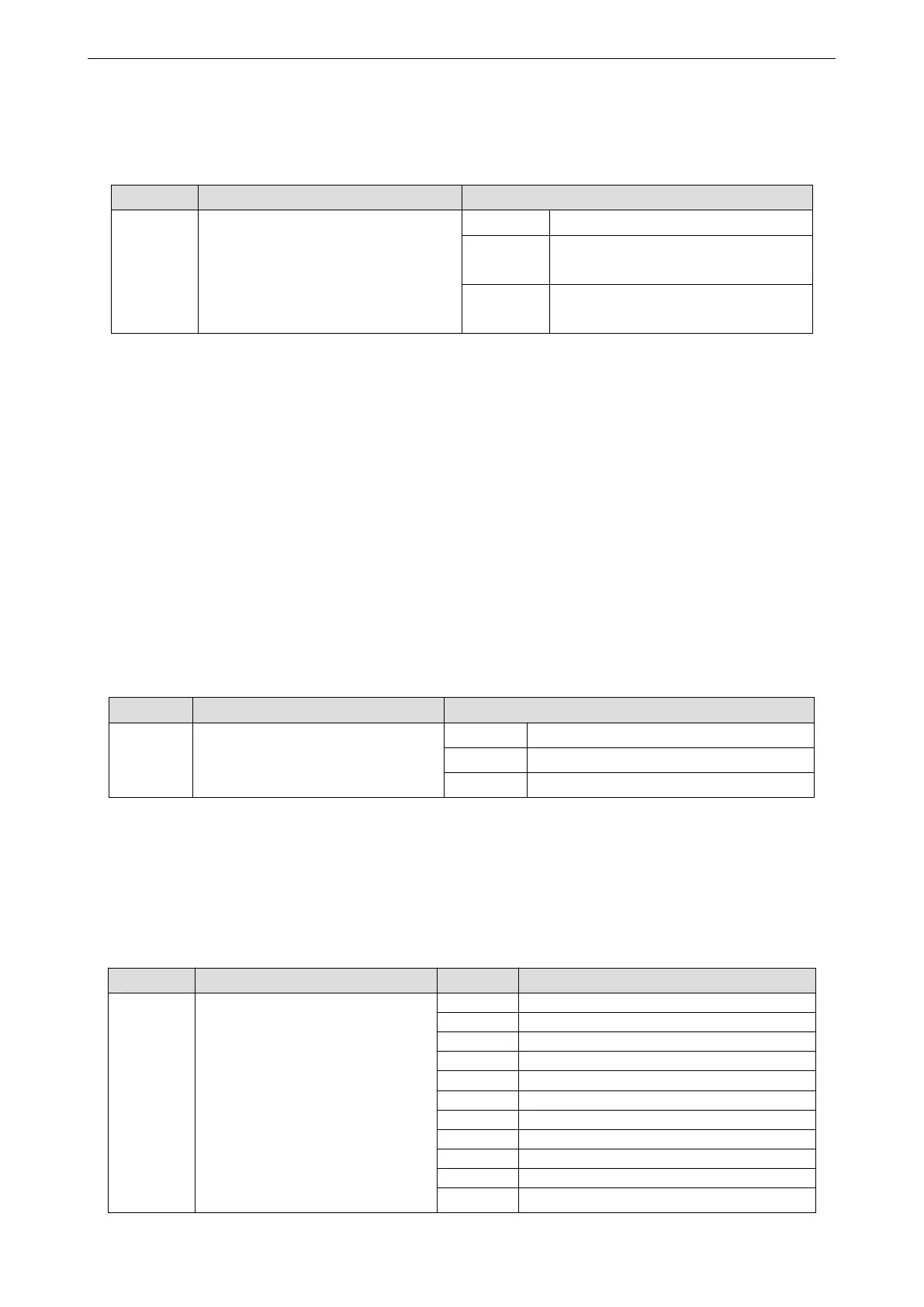

Operation command channel

selection

0: Operate panel

Controlled by the key on the operate panel.

1: Terminal

Controlled by multi-function terminals.

2: Communication port

Controlled by upper PC via communication.

Main frequency source A channel

selection

Digital setting (Power-off no memory)

Digital setting (Power-off memory)

X4 terminal pulse setting

Multi-segment command setting

Specific mode for wire drawing and

Loading...

Loading...