203

8. Maintenance

The change of the operating environment of the inverter, such as the influence of temperature, humidity, smoke,

etc., and aging of the internal components of the converter, may lead to various faults of the inverter. Therefore,

the inverter must be checked daily during storage and use, and regular maintenance should be carried out.

8-1. Routine maintenance

When the frequency converter is turned on normally, please confirm the following items:

(1) Whether the motor has abnormal sound and vibration.

(2) Whether the frequency converter and motor have abnormal heating.

(3) Whether the ambient temperature is too high.

(4) Whether the load ammeter is the same as usual.

(5) Check whether the cooling fan of frequency converter operates normally.

8-2. Regular maintenance

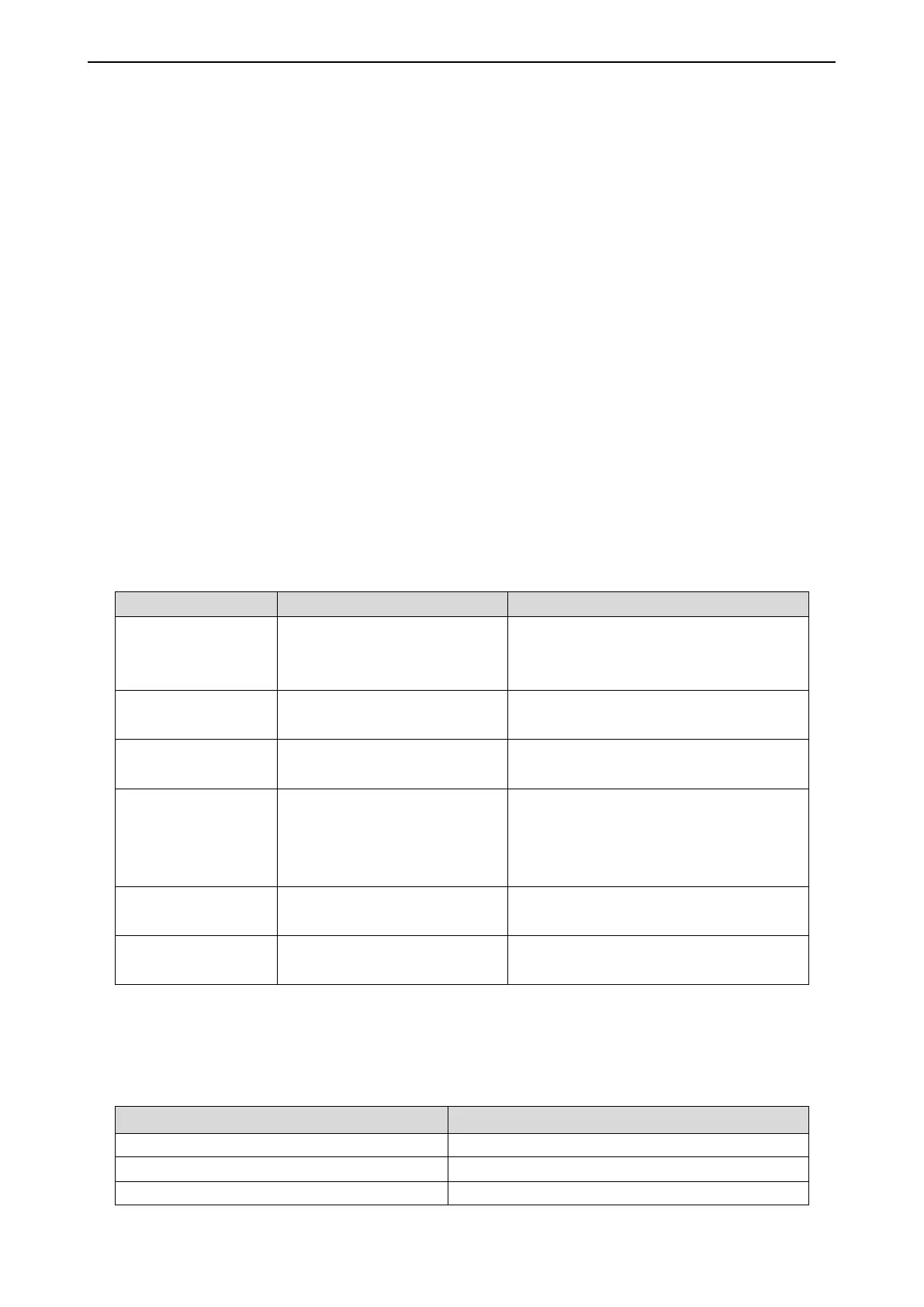

When the frequency converter is regularly maintained and inspected, it is necessary to cut off the power supply,

and the inspection can only be carried out after the monitor is not displayed and the power indicator of the main

circuit is off. The inspection contents are shown in the table below.

Screw of main circuit

terminal and control

circuit terminal

Whether the screws are loose

Tighten with a screwdriver

Blow off with 4 ~ 6kgcm

2

dry compressed

air

Blow off with 4 ~ 6kgcm

2

dry compressed

air

Whether there is abnormal

sound and vibration, and the

accumulated operation time is

up to 20000 hours

Blow off with 4 ~ 6kgcm

2

dry compressed

air

Aluminum

electrolytic capacitor

Whether discoloration, odor,

blistering

Replace the Aluminum electrolytic

capacitor

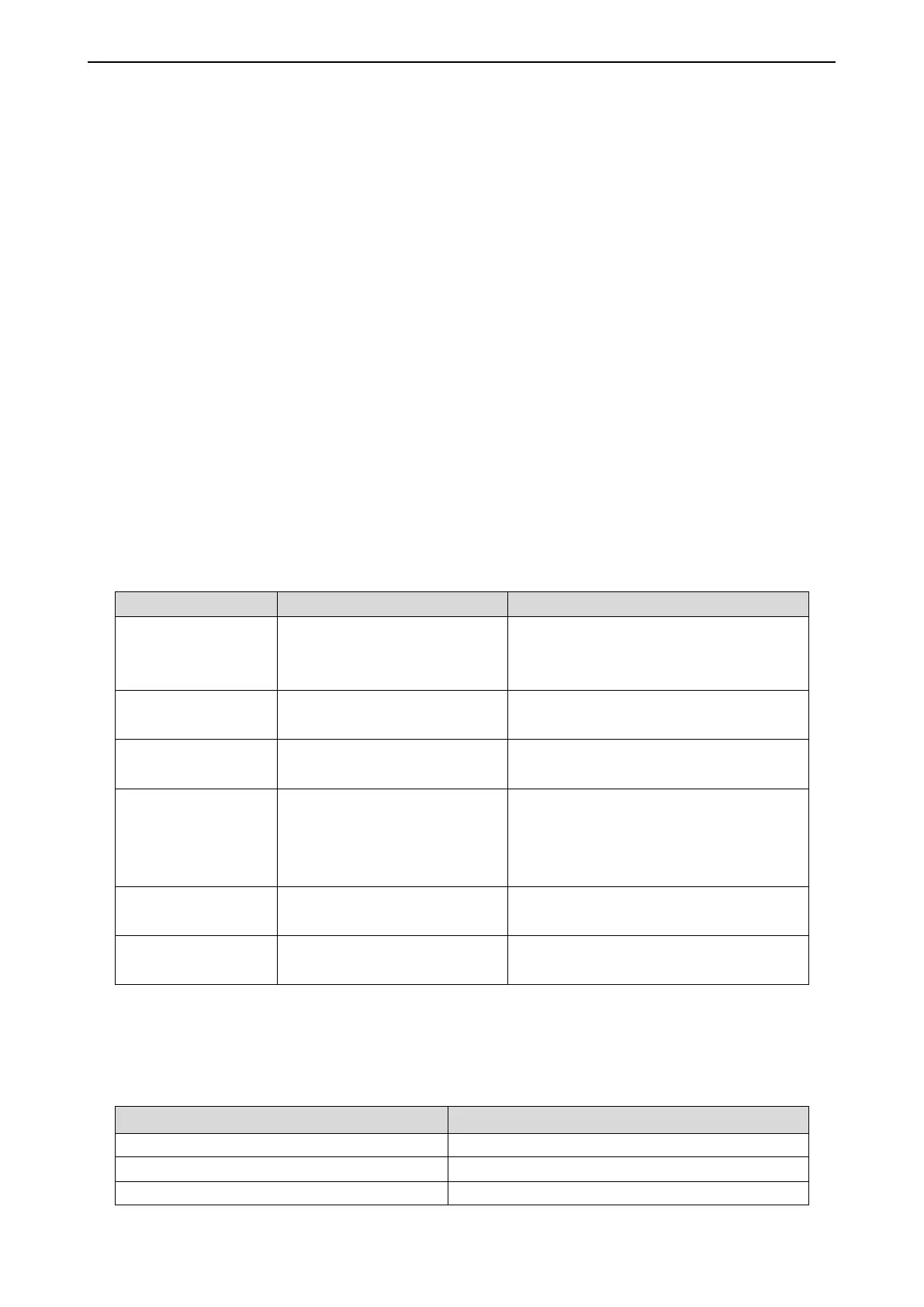

In order to make the inverter work normally for a long time, regular maintenance must be carried out according

to the service life of the internal electronic components of the inverter. The service life of electronic components

of frequency converter is different because of its different environment and conditions. As shown in the table

below, the maintenance period of frequency converter is only for users' reference.

Standard replacement years

Loading...

Loading...