3-38

1

2

3

4

5

6

7

8

9

10

ENGINE

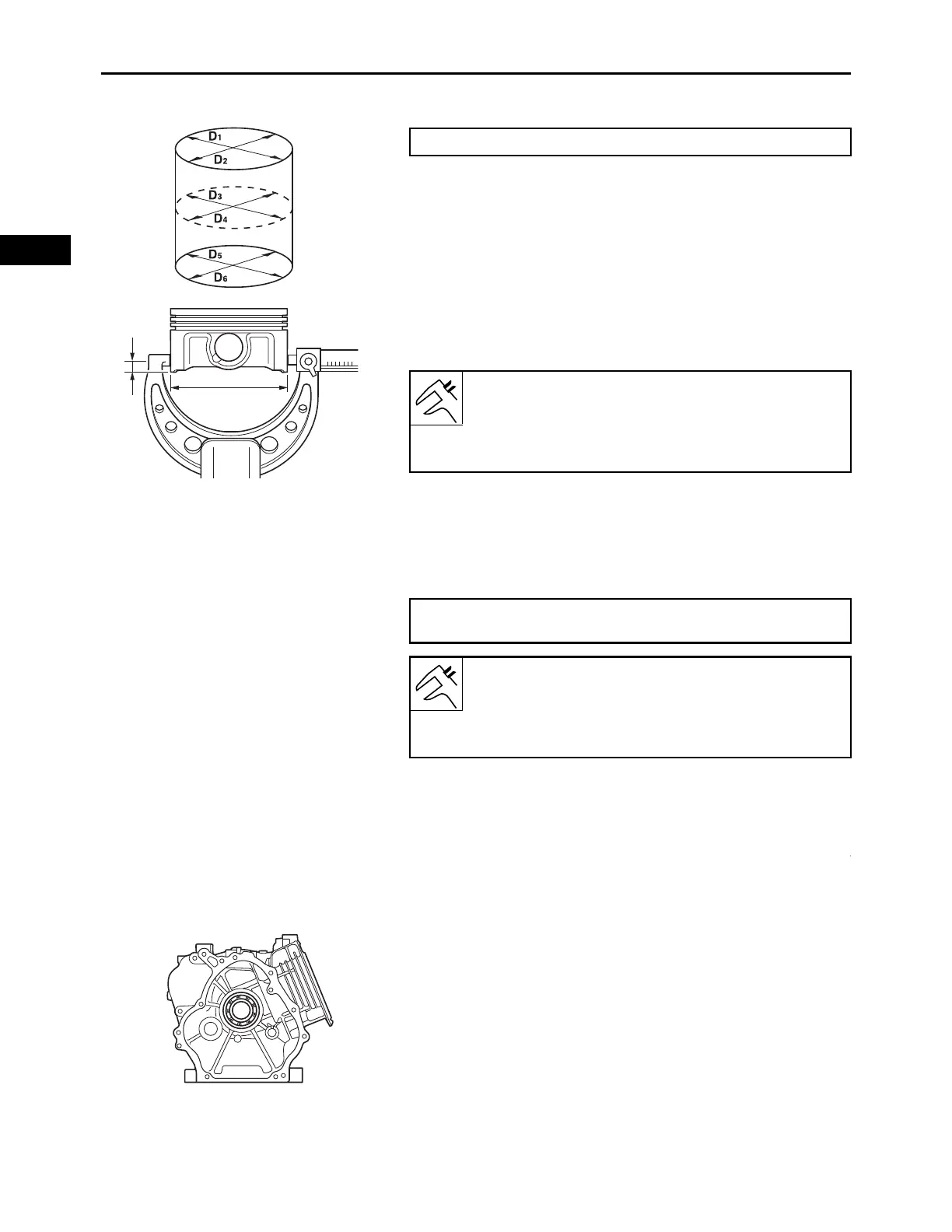

PISTON, CAMSHAFT, CRANKCASE, AND CRANKSHAFT

b. If out of specification, replace the crankcase

assembly, and replace the piston and piston rings

as a set.

c. Measure piston skirt diameter “P” with the microm-

eter.

a = 10 mm (0.4 in) from the piston bottom edge

d. If out of specification, replace the piston and piston

rings as a set.

e. Calculate the piston-to-cylinder clearance with the

following formula.

f. If out of specification, replace the crankcase

assembly, and replace the piston and piston rings

as a set.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

CHECKING THE CRANKCASE

1.

Check:

•Crankcase

Damage Replace.

• Bearing

Noise/wear/rotational failure Replace.

“C” = maximum of D

1

, D

2

, D

3

, D

4

, D

5

, D

6

Piston diameter:

79.96–79.98 mm (3.1480–3.1488 in)

Limit:

79.91 mm (3.1461 in)

Piston-to-cylinder clearance = Cylinder bore “C” – Piston skirt

diameter “P”

Piston-to-cylinder clearance:

0.033–0.047 mm (0.0012–0.0018 in)

Limit:

0.06 mm (0.0024 in)

Loading...

Loading...