7 Wiring

7.2.5 I/O Signals

7-28

7.2.5 I/O Signals

(1) Connections

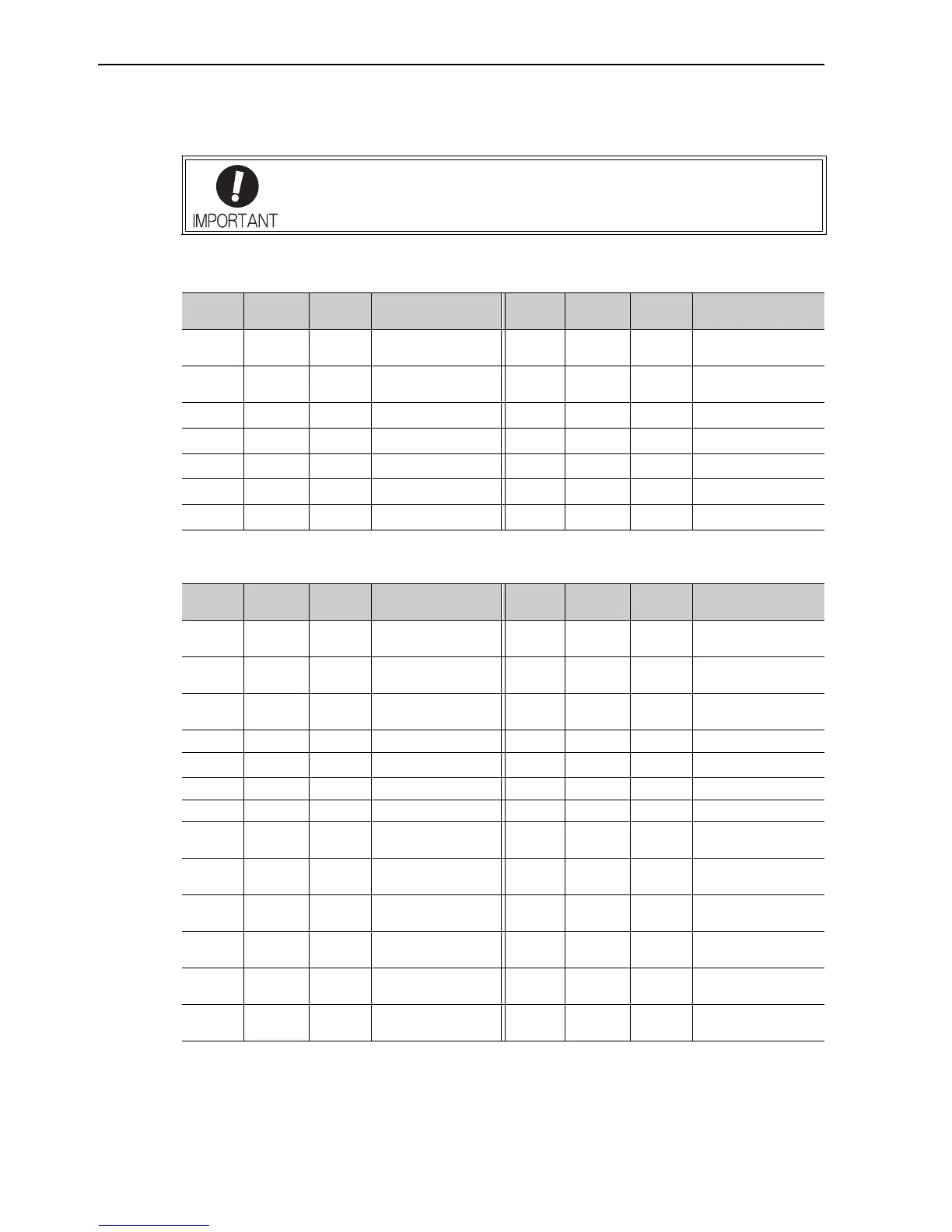

Connector Pin Arrangement (CN1) for I/O Signals of the Power Regeneration Converter

∗ Do not use NC signal.

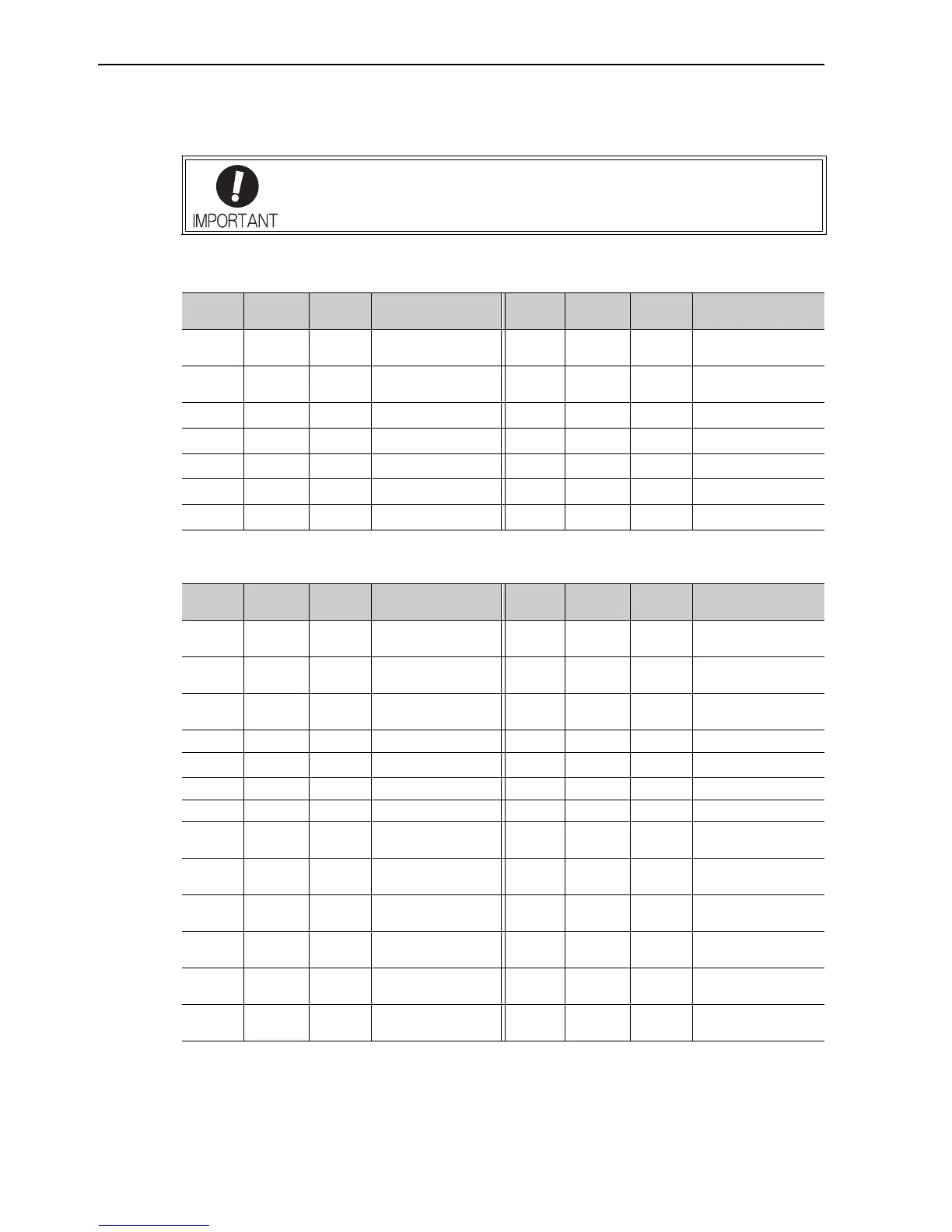

Connector Pin Arrangement (CN1) for I/O Signals of the SERVOPACK for One Axis

∗1. Do not use NC signal.

∗2. Use CN1 or CN3 for motor winding temperature detection.

Do not use CN1 on the SERVOPACK as the I/O signal for an emergency stop.

Use CN1 on the power regeneration converter.

Pin No.

Signal

Name

I/O Function Pin No.

Signal

Name

I/O Function

1 /MCON+ O

Main circuit connector

ON output

8

*

(NC) – –

2 /MCON– O

Main circuit connector

ON output

9

*

(NC) – –

3

*

(NC) – –

10

*

(NC) – –

4

*

(NC) – – 11 /ESP+ I Emergency stop input

5

*

(NC) – – 12 /ESP– I Emergency stop input

6

*

(NC) – –

13

*

(NC) – –

7

*

(NC) – –

14

*

(NC) – –

Pin No.

Signal

Name

I/O Function Pin No.

Signal

Name

I/O Function

1 COM24V I

+24V external power

supply input

14

*1

(NC) – –

2 /Probe1 I

Probe 1 latch signal

input

15

*1

(NC) – –

3 /Probe2 I

Probe 2 latch signal

input

16

*1

(NC) – –

4 /Home I Home switch input 17 /HWBB1– I Baseblock input 1

5

*1

(NC) – – 18 /HWBB1+ I Baseblock input 1

6 P-OT1 I Forward overtravel 19 /HWBB2– I Baseblock input 2

7 N-OT1 I Reverse overtravel 20 /HWBB2+ I Baseblock input 2

8

*1

(NC) – – 21 EDM1– O

Baseblock monitoring

signal

9 /BK1+ O Brake 22 EDM1+ O

Baseblock monitoring

signal

10 /BK1– O Brake 23 DBA1 I

External dynamic

brake answer signal

11

*2

THM1+ I

Motor winding temper-

ature detection

24 DBA2 I

External dynamic

brake answer signal

12

*2

THM1– I

Motor winding temper-

ature detection

25 DBON O

External dynamic

brake

13

*1

(NC) – – 26 DB24V O

External dynamic

brake

Loading...

Loading...