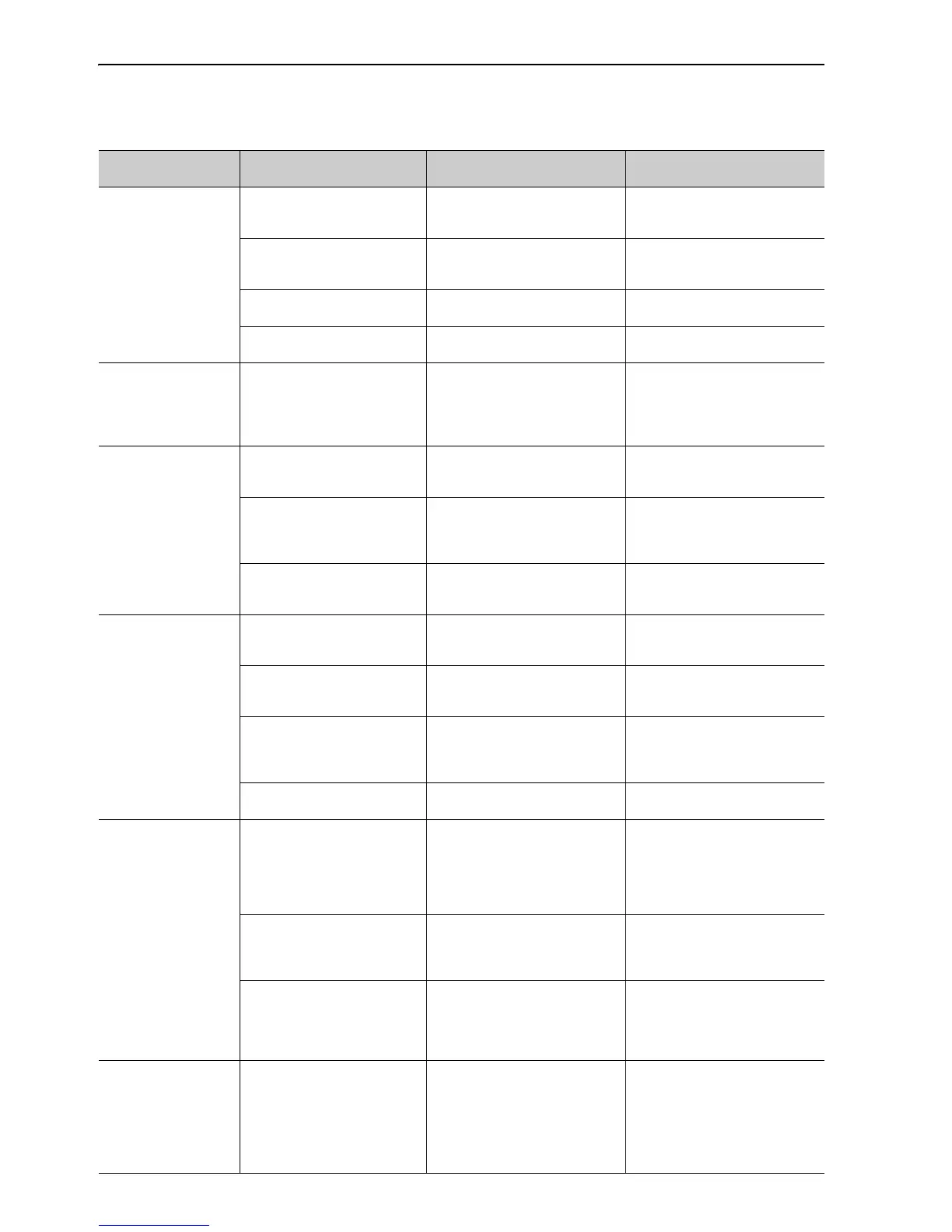

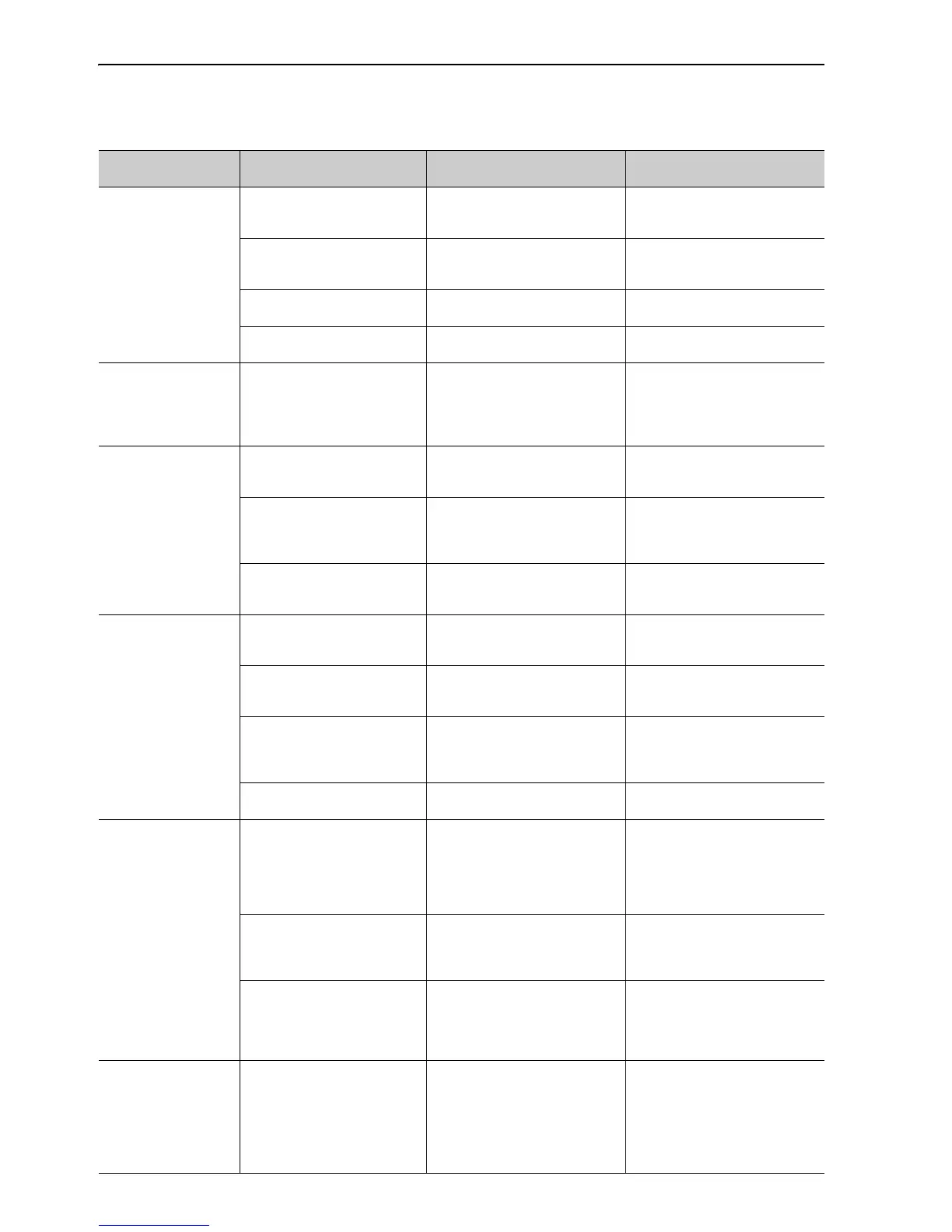

11 Inspection, Maintenance, and Troubleshooting

11.2.3 Troubleshooting of the Servo Drive Alarms

11-20

A.510:

Overspeed

(The servomotor speed

exceeds the maximum.)

The order of phases U, V, and W

in the servomotor wiring is incor-

rect.

Check the servomotor wiring.

Confirm that the servomotor is cor-

rectly wired.

A reference value exceeding the

overspeed detection level was

input.

Check the input value.

Reduce the reference value or adjust

the gain.

The motor speed exceeded the

maximum.

Check the servomotor speed wave-

form.

Adjust the servo gain, or reconsider

the operation conditions.

SERVOPACK failure −

The SERVOPACK may be faulty.

Replace the SERVOPACK.

A.521:

Autotuning Alarm

(Vibration was detected

during one-parameter

tuning or Easy-FFT.)

Excessive vibration was detected

in the motor during one-parame-

ter tuning.

Check the speed waveform of the

motor.

Perform the corrective action for the

operating procedure for the func-

tion.

A.531:

Excessive Speed

Deviation

(The deviation between

the speed reference and

actual motor speed is

abnormal.)

The motor main circuit cable is

either incorrectly wired or has a

contact fault.

Make sure the wiring is correct. Correct the wiring.

A short-circuit or ground fault

occurred in the motor main cir-

cuit cable.

Check for short-circuits across

phase U, V, and W of the cable, or

between the ground and phase U, V,

or W.

The cable may have short-cir-

cuited. Replace the cable.

The load is heavy (for example,

the cutting resistance may be

high).

Check to see if the load friction is

high and the moment of inertia of

the load is too high.

Remove the load.

A.540:

Overspeed (During

Low-speed Winding)

(The low-speed winding

maximum speed was

exceeded during low-

speed winding.)

The sequence of phase U, V, and

W motor lines is incorrect.

Check the wiring of the motor and

of the electromagnetic contactor for

winding selection.

Correct the motor wiring.

The reference input value

exceeds the maximum speed of

the low-speed winding.

Check the input reference.

Reduce the reference value, or

adjust the gain.

The low-speed winding maxi-

mum rotation speed was

exceeded during low-speed wind-

ing.

Check the motor speed from the

motor speed monitor in SigmaWin

for the Σ-V-SD (MT).

Adjust the gain, or revise the oper-

ating conditions.

SERVOPACK failure −

The SERVOPACK may be faulty.

Replace the SERVOPACK.

A.690:

Winding Selection

Operation Fault

During the winding selection

check that is performed when the

power is turned ON, the electro-

magnetic contactor for winding

selection

did not change accord-

ing to the internal command.

Check the wiring of the SERVO-

PACK a nd o f the electromagnetic

contactor for winding selection.

Correct the wiring of the winding

selection signal.

Winding selection was not com-

pleted within two seconds of

receiving the winding selection

command.

Check the wiring of the electromag-

netic contactor for winding selec-

tion.

Correct the wiring of the electro-

magnetic contactor for winding

selection.

Chattering occurred in the elec-

tromagnetic contactor for wind-

ing selection when the winding

selection command was not

received.

Check the wiring of the electromag-

netic contactor for winding selec-

tion.

Correct the wiring of the electro-

magnetic contactor for winding

selection, or replace the electromag-

netic contactor for winding selec-

tion.

A.6B0:

Emergency Stop

Failure

(The motor did not stop

within 10 s after the

emergency stop signal

input.)

The set value of the emergency

stop torque in Pn406 is too small.

−

Correct the emergency stop torque

setting in Pn406.

(cont’d)

Alarm:

Alarm Name

Cause Investigative Actions Corrective Actions

Loading...

Loading...