2.1.3 PWM (Pulse Width Modulation) with DC Voltmeter

A Ensure power is removed from both the Engine Electronics and the Processor.

B Disconnect the Throttle Harness from the number 1 Processor connector/pigtail.

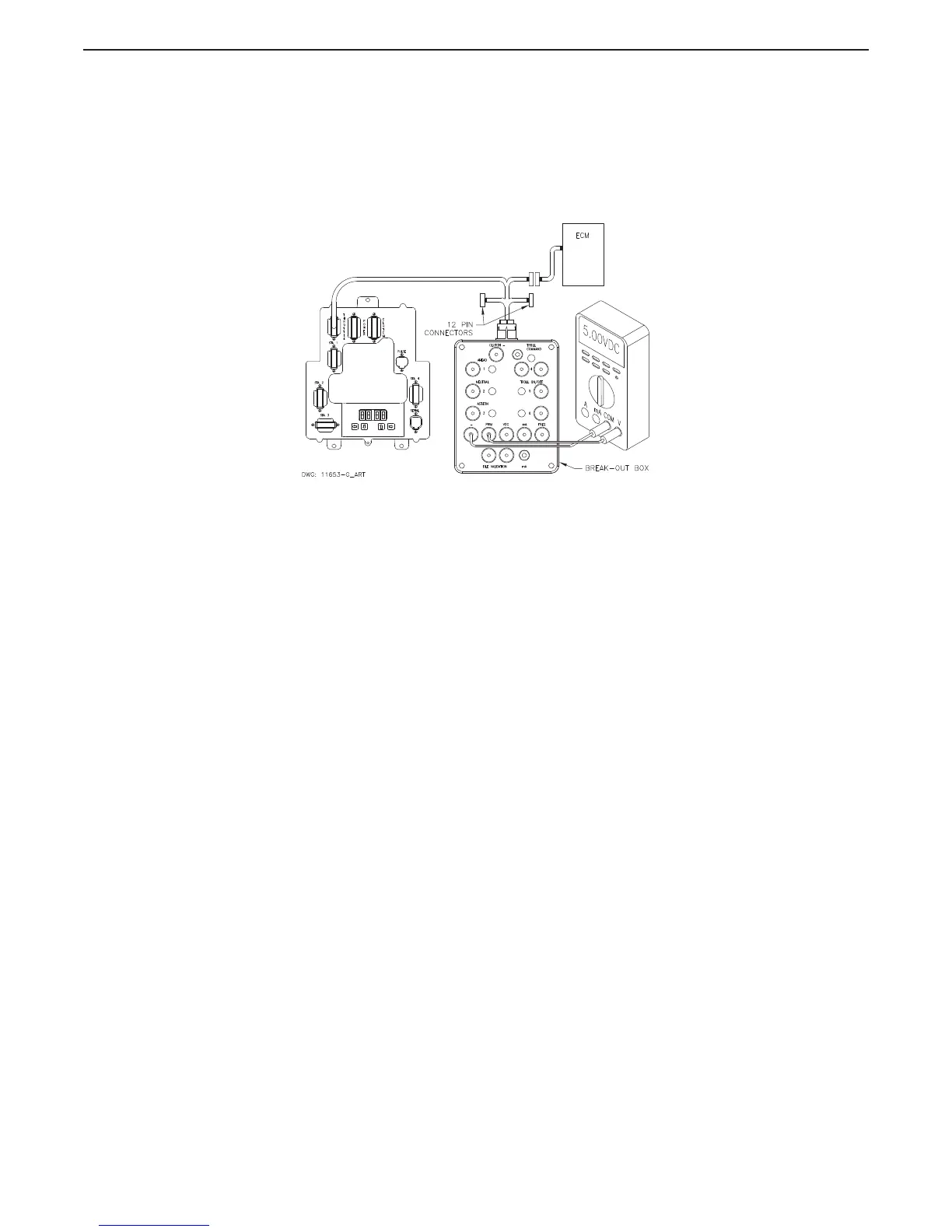

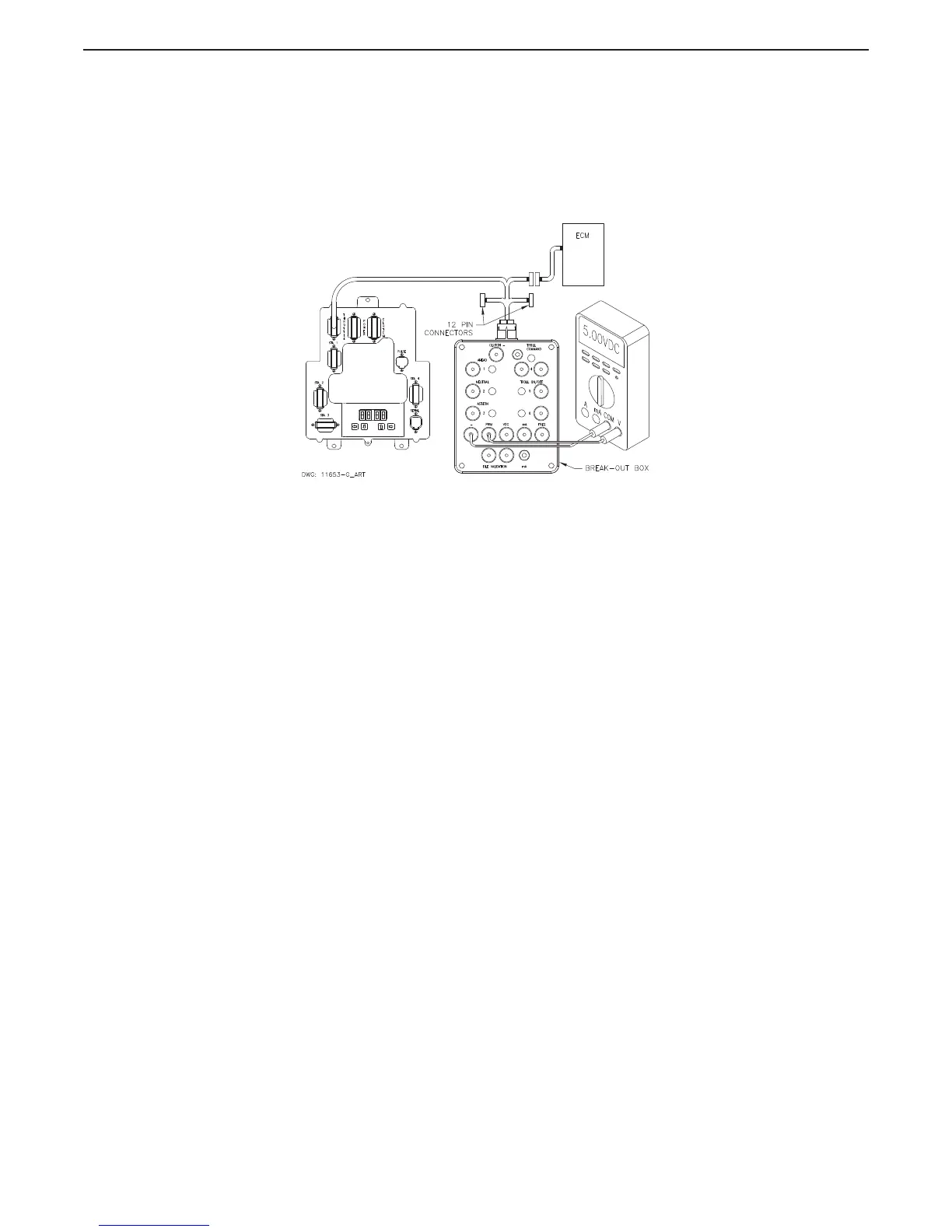

C Insert the Break-out Box between the number 1 Processor connector/pigtail and the Throttle

Harness as shown in Figure MM13927-6: Throttle Connection (PWM with DC Voltmeter)

labeled “-” and the red lead into the socket labeled “PWM”.

Figure MM13927-6: Throttle Connection (PWM with DC Voltmeter)

D Turn power ‘On’ to the Caterpillar ECM (Electronic Control Module) Only. Do Not apply

power to the Processor at this time.

E Depending on the type of Caterpillar ECM (PEEC or ADEMS), the measurement should be

approximately 5.00 or 12.00 VDC. Record the measurement as shown in Drawing Figure

MM13927-6: Throttle Connection (PWM with DC Voltmeter).

F Set up the Multimeter to DC Volts and plug the black lead into the Break-out Box black

socket Turn power ‘On’ to the Processor and take command at any Remote Station.

G Record the DC Voltage at this time. The measurement should be 7- 9% of the voltage

measured in step F).

H Move the Control Head lever to the Full Throttle position while depressing the Transfer

Button (Throttle Only Mode).

I The measurement should be 91- 93% of the voltage measured in step F) [e.g. Idle = 8% of

12 VDC reference or 0.96 VDC; Full Throttle = 92% of 12 VDC reference or 11.04 VDC.

2.1.4 PWM (Pulse Width Modulation) with Duty Cycle Meter

A Ensure power is removed from both the Engine electronics and the Processor.

B Disconnect the Throttle Harness from the number 1 Processor connector/pigtail.

Loading...

Loading...