243D Systems, Inc.

READING THE Z-GAP CALIBRATION PRINT

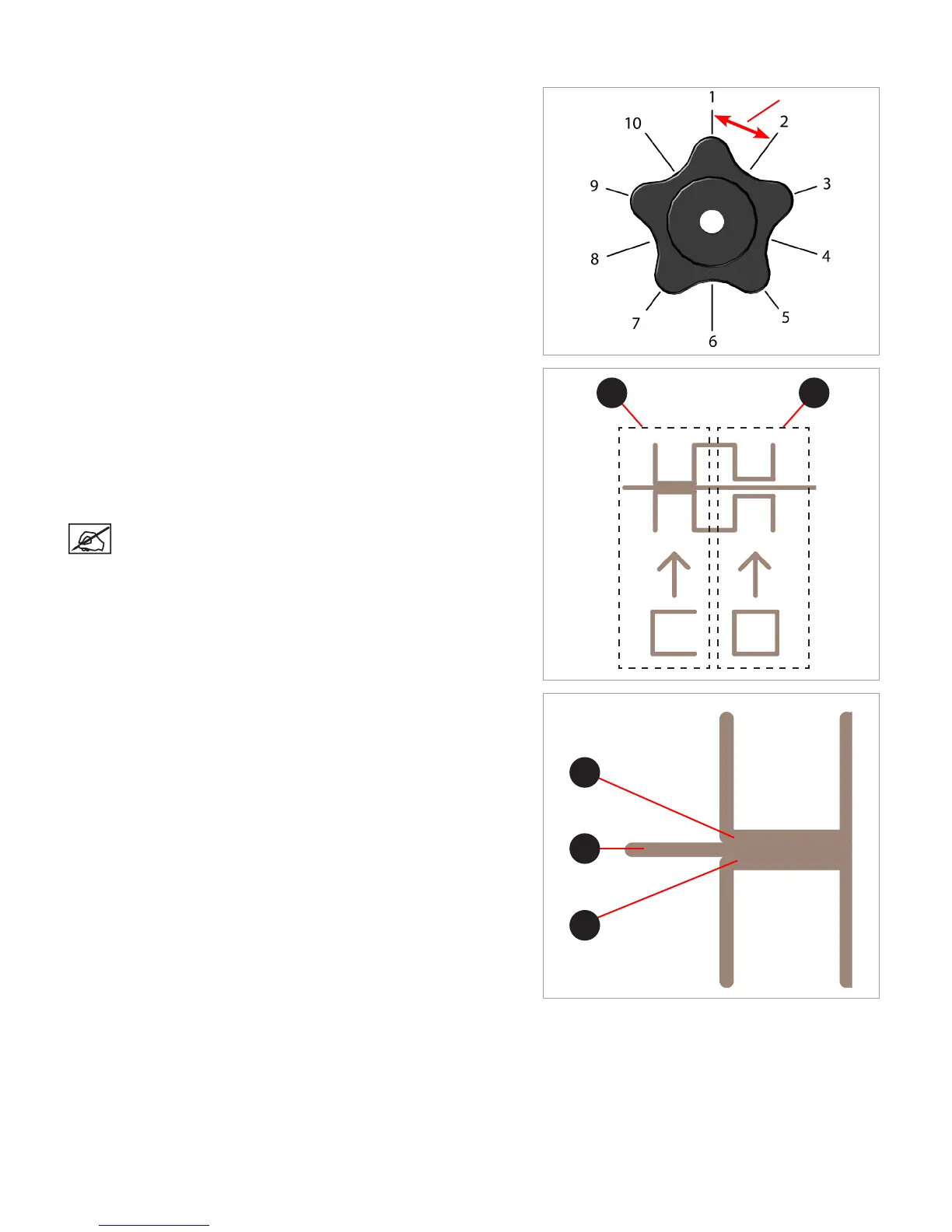

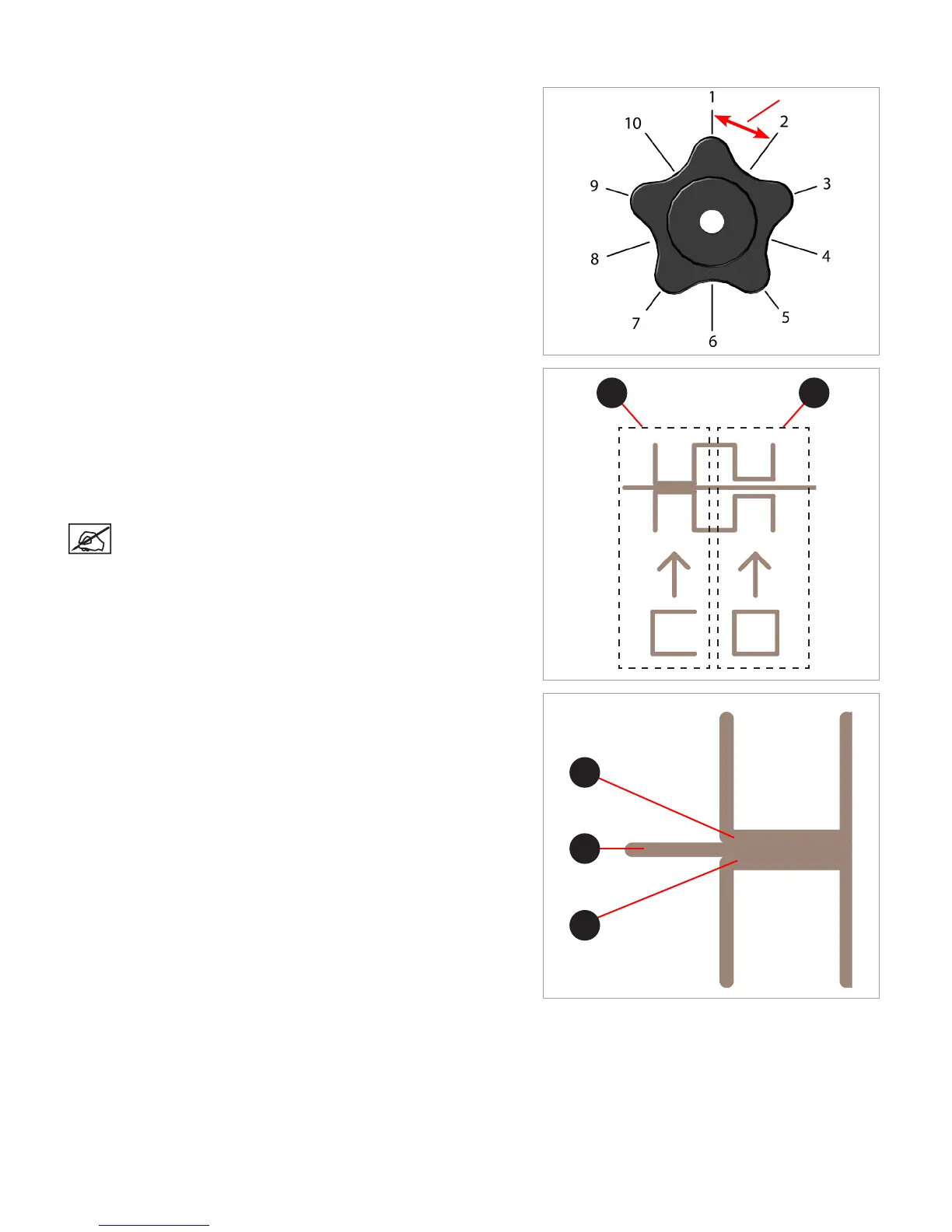

Adjustment Knob Measurement

Adjusting the level plate adjustment knobs should initially be performed

in 1-step increments. If a ner adjustment becomes necessary, adjust the

knobs in 1/2 step increments.

In the illustration, the measurement between 1 and 2 is considered 1-step.

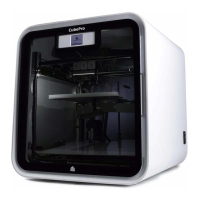

Adjusting the Z-Gap

After installing material cartridges for the rst time, the Z-Gap and the Print

Pad Level should be veried before printing. The Z-Gap should be within

specications before adjusting the Level Gap. If adjustments to the Z-Gap

are necessary, perform the adjustments and then print the calibration le

again to verify the correct Z-Gap. A correct Z-Gap is indicated when there is

no gap in the Closed Z-Gap measurement and there is a gap in the Open

Z-Gap measurement.

NOTE: The Closed Z-Gap (A) and the Open Z-Gap (B) are two

different measurements but should be read together.

Correct Closed Z-Gap

The Closed Z-Gap bars (B) should touch the baseline (A).

A

B

B

1-Step

A B

Loading...

Loading...