Required equipment

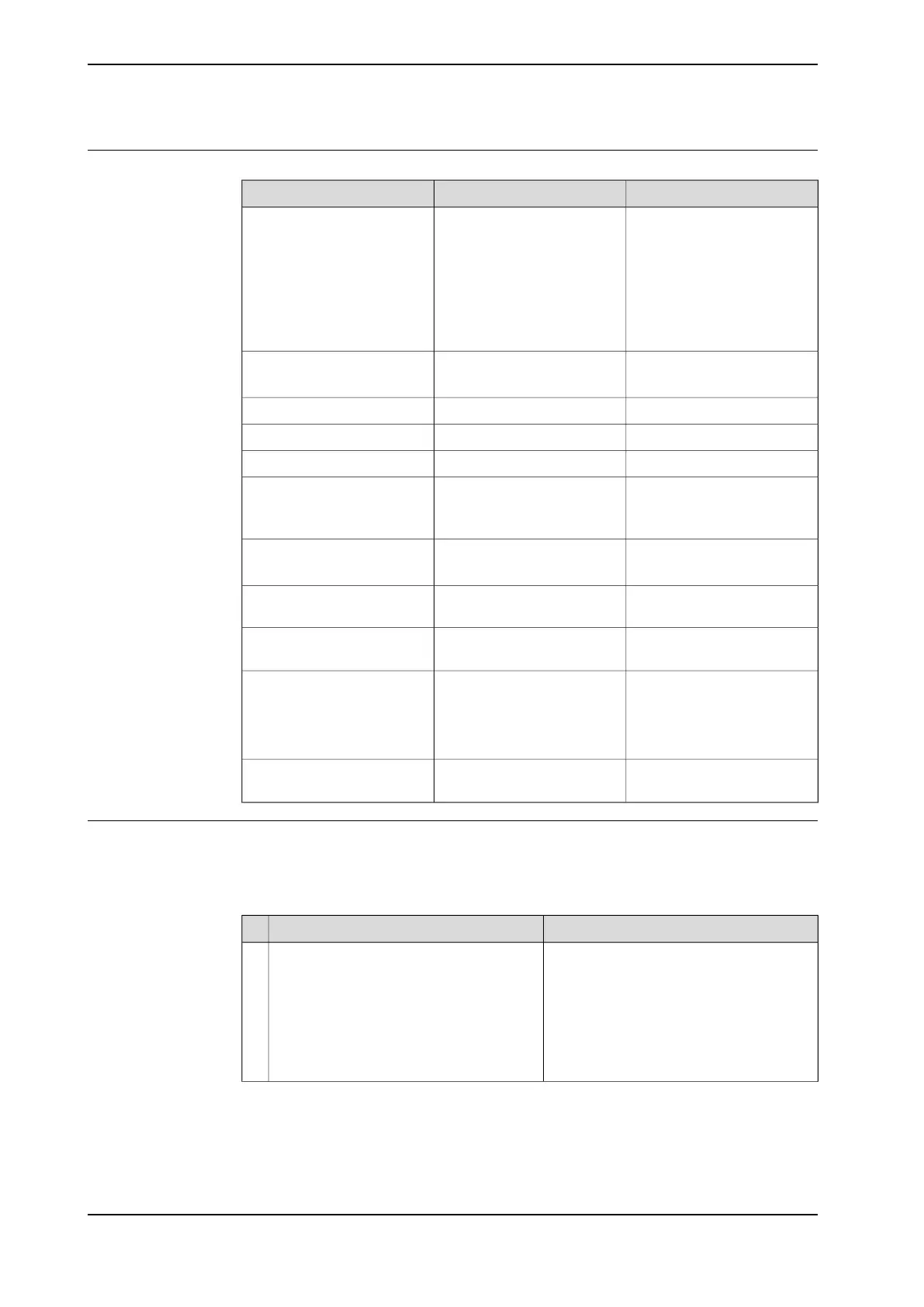

NoteArt. no.Equipment, etc.

Used to guide the complete

arm system when refitting.

3HAC022637-001Guide pins M12 x 130

Always use the guide pins in

pairs!

Guide pins that are longer

than 140 mm will not be pos-

sible to remove because the

lack of space.

4 pcs.Roundsling

Lifting capacity 1,000 kg

3HAC040381-001Adapter

3HAC025333-005Lifting eye, M12

Lifting capacity: 1,000 kg.-Shackle

Stahlwille 736/40 D10 (or

similar)

-Bits holder

Used on the M12x140 screws.

24 VDC, max. 1.5 A-Power supply

For releasing the brakes.

Used to turn the gear when

mating it to the frame.

-Crank

Content is defined in section

Standard tools on page 383.

-Standard toolkit

These procedures include

references to the tools re-

quired.

Other tools and procedures

may be required. See refer-

ences to these procedures in

the step-by-step instructions

below.

See chapter Circuit diagrams

on page 391.

-Circuit diagram

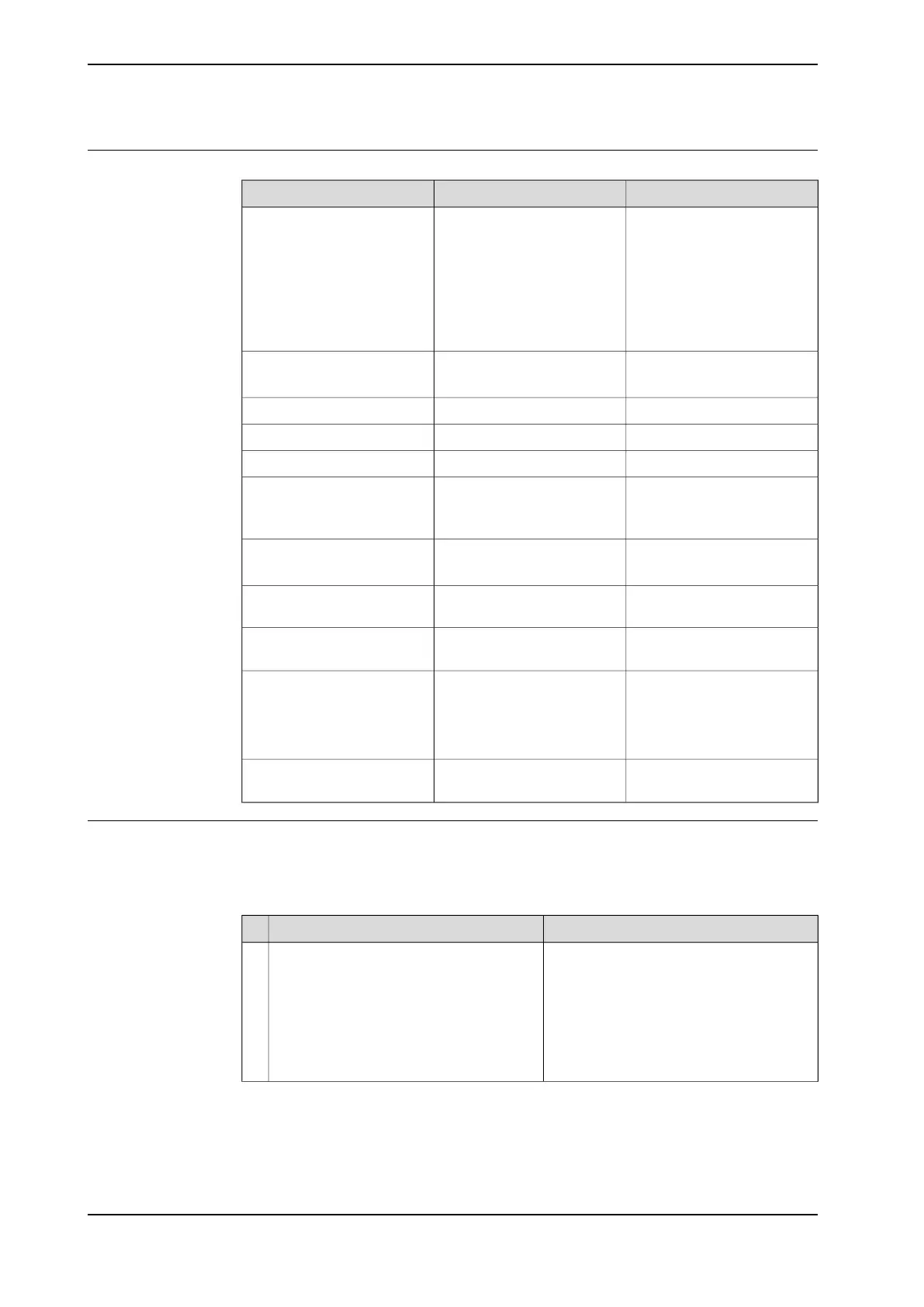

Deciding calibration routine

Decide which calibration routine to be used, based on the information in the table.

Depending on which routine is chosen, action might be required prior to beginning

the repair work of the robot, see the table.

NoteAction

Decide which calibration routine to use for

calibrating the robot.

• Reference calibration. External cable

packages (DressPack) and tools can

stay fitted on the robot.

• Fine calibration. All external cable

packages (DressPack) and tools

must be removed from the robot.

1

Continues on next page

174 Product manual - IRB 460

3HAC039842-001 Revision: P

© Copyright 2012-2018 ABB. All rights reserved.

4 Repair

4.3.5 Replacing the base, including axis 1 gearbox

Continued

Loading...

Loading...