4 Repair

4.7.3. Replacement of gearbox, axis 3

3833HAC022033-001 Revision: K

© Copyright 2004-2011 ABB. All rights reserved.

Refitting, gearbox axis 3

The procedure below details how to refit gearbox, axis 3.

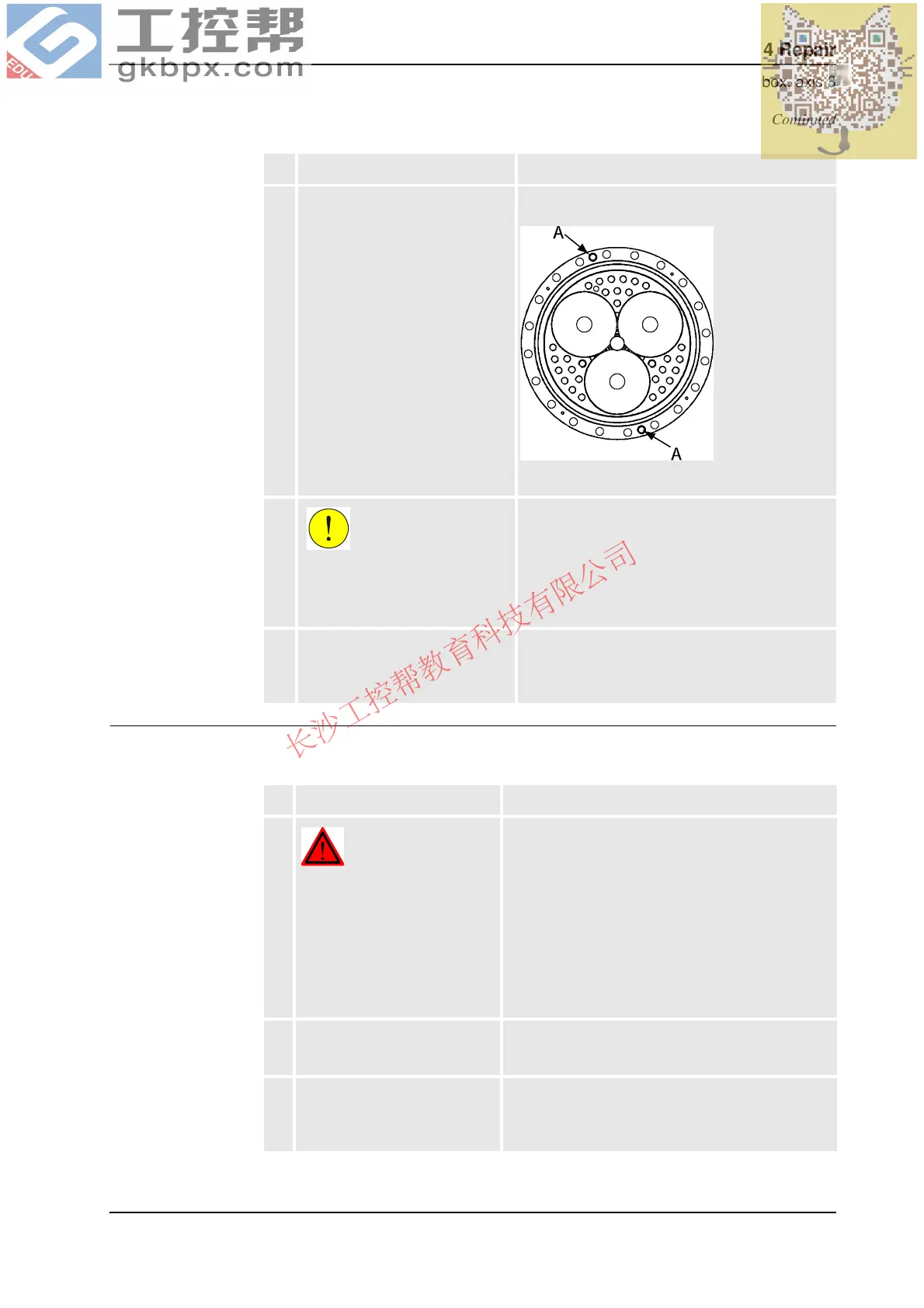

9. Fit the lifting eye to the gearbox, in

one of the attachment screw holes

that attaches the gearbox to the

lower arm .

If required, use screws in the holes

(A) shown in the figure to the right

to press the gearbox free.

Art. no. is specified in Required equipment on page

381.

xx0200000033

• A: M16 holed for pressing the gearbox out

10.

CAUTION!

The gearbox weighs 125 kg! All

lifting equipment used must be

sized accordingly!

11. Remove the gearbox, with

guidance from the guide pins,

using an overhead crane or

similar.

Action Note

Action Note

1.

DANGER!

Turn off all electric power,

hydraulic and pneumatic

pressure supplies to the robot!

Turn off all electric power and

hydraulic but not the air

pressure to the gearboxes,

motors and SMB.

2. Turn the upper arm in such a

position that the gear mating

surface faces upwards.

3. Fit two guide pins in 180°

relation to each other in the

holes in the upper arm, used for

the gearbox attachment screws.

Art. no. is specified in Required equipment on page

381.

Continued

Continues on next page

Loading...

Loading...