4 Repair

4.7.3. Replacement of gearbox, axis 3

3HAC022033-001 Revision: K384

© Copyright 2004-2011 ABB. All rights reserved.

4.

CAUTION!

The gearbox weighs 125 kg! All

lifting equipment used must be

sized accordingly!

5. Fit the lifting eye to the gearbox. Art. no. is specified in Required equipment on page

381.

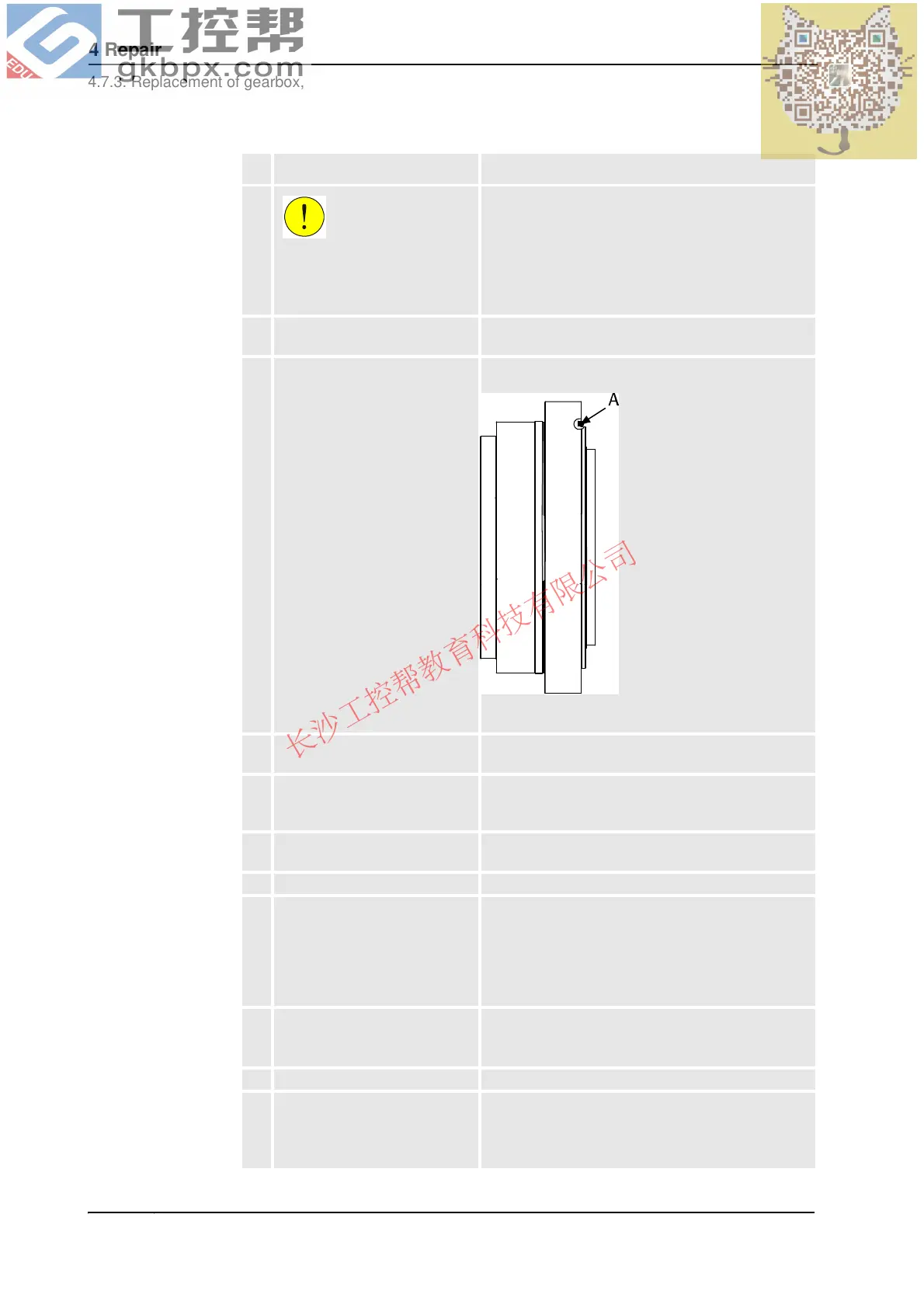

6. Make sure the o-ring is fitted to

the rear of the gearbox. Apply

grease to it to make sure it sticks

in its groove during assembly!

Replace if damaged!

Art. no. is specified in Required equipment on page

381.

xx0100000136

• A: O-ring, gearbox axis 3

7. Lift the gearbox to its mounting

position.

8. Turn the gearbox to align the

attachment screw holes with

those in the upper arm.

9. Fit the gearbox onto the guide

pins and slide it into position.

Make sure the o-rings are seated properly and the

gearbox correctly oriented!

10. Remove the lifting tool.

11. Secure the gearbox with 18 of

the 20 gearbox attachment

screws.

Remove the guide pins and

tighten the remaining two

screws.

20 pcs: M16 x 90; 12.9 quality UNBRAKO, tightening

torque: 300 Nm.

Reused screws may be used, providing they are

lubricated as detailed in section Screw joints on page

423 before fitting.

12. Refit the upper arm with a new

sealing, axis 2/3 .

Art. no. is specified in Required equipment on page

381.

Detailed in section Refitting, upper arm on page 285.

13. Refit the motor. Detailed in section Refitting, motor on page 344.

14. Recalibrate the robot! Calibration is detailed in a separate calibration

manual enclosed with the calibration tools.

General calibration information is included in section

Calibration information on page 403.

Action Note

Continued

Continues on next page

Loading...

Loading...