304 Agilent 1260 Infinity DAD and MWD User Manual

14

Appendix

Installation of Stainless Steel Cladded PEEK Capillaries

First installation of a capillary to a hard connector

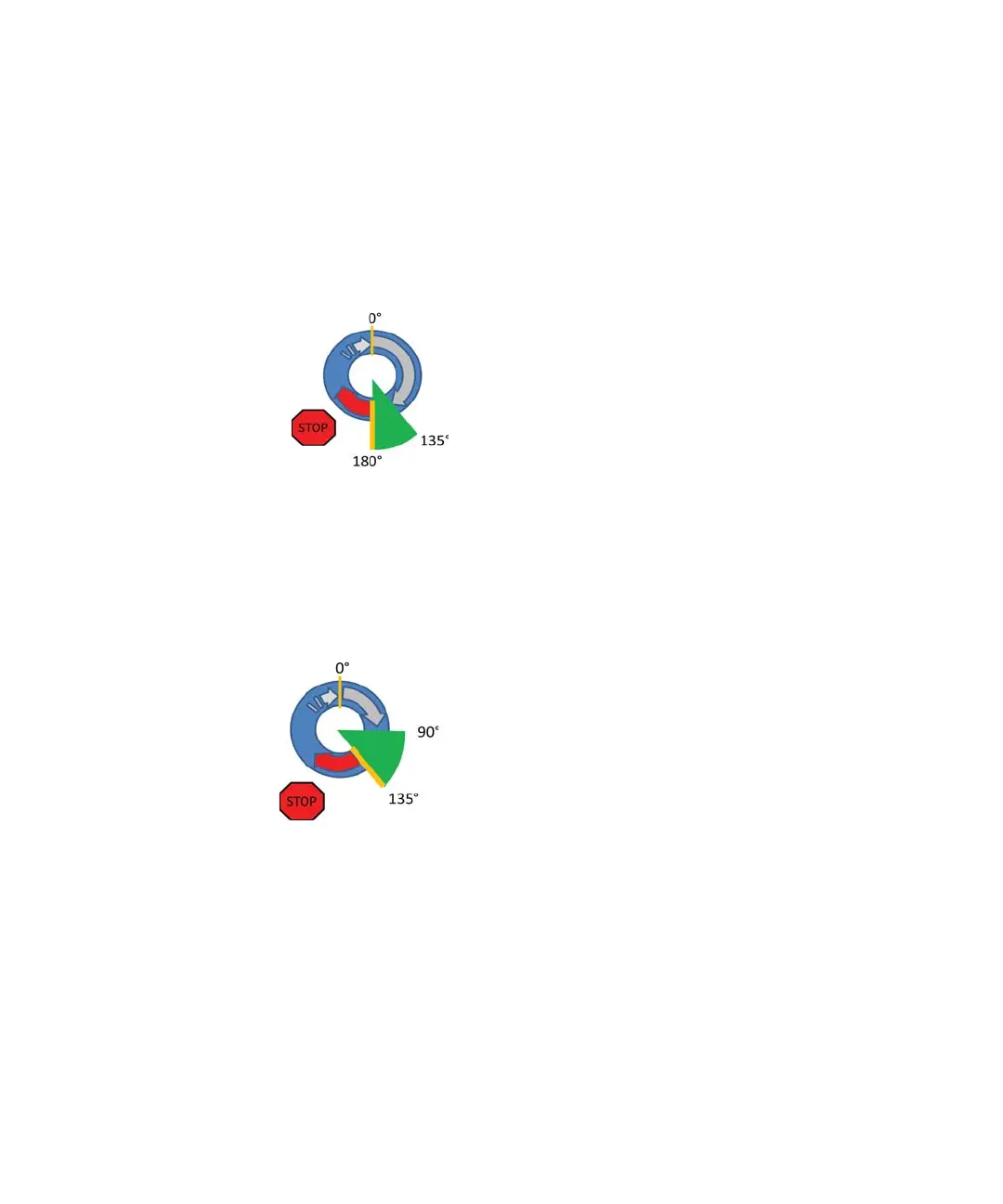

1 When tightening a fitting for the first time, start from the finger-tight

position (which is not necessarily a vertical wrench position) and rotate the

wrench by 135 – 180 °. Staying below 135 ° (grey arrow) will be

insufficiently tight, more than 180 ° (red arrow) could damage the

capillary.

Second and subsequent installations of a capillary to a hard connector

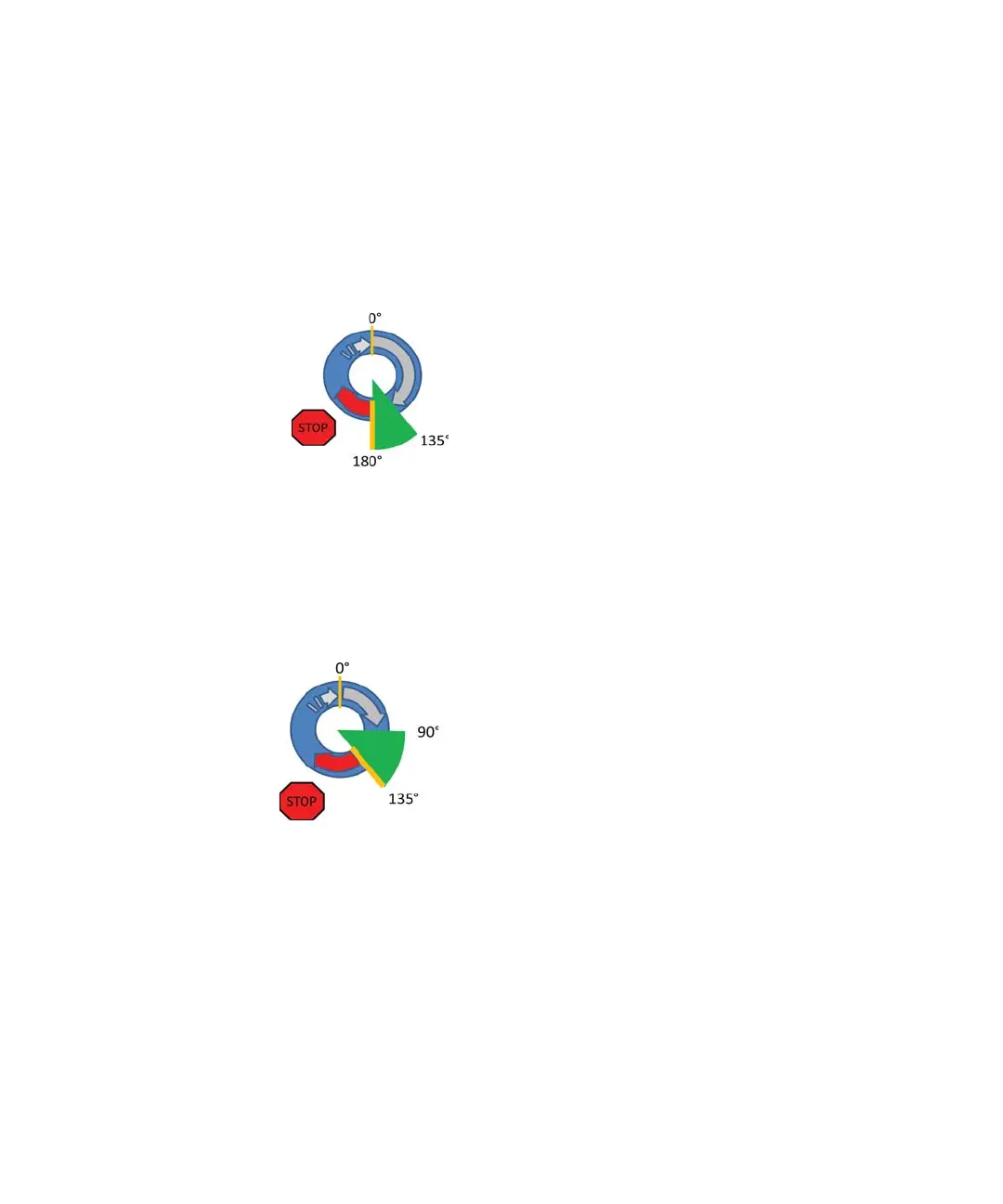

1 When tightening the fitting for the second and subsequent times, again start

from the finger-tight position (which is not necessarily a vertical wrench

position) and rotate the wrench by 90 – 135 °. Staying below 90 ° (grey

arrow) could be insufficiently tight, more than 135 ° (red arrow) could

damage the capillary.

Second Step: Installation to Soft Connectors

Use this procedure for soft connectors, which are typically made from PEEK.

These are the following connections:

• to and from all bio-inert valves (injection valve in the autosampler and

valves in the thermostatted column compartment and 1290 Infinity Valve

Drive),

• bio-inert ZDV unions (detector flow cells, multi-draw upgrade kit, capillary

to capillary connections, for example, for heat exchangers),

SRVVLEO\

OHDN\

UHFRPPHQGHG

UDQJH

SRVVLEO\

OHDN\

UHFRPPHQGHG

UDQJH

Loading...

Loading...