69

Chapter 4: Sealing plates

PlateLoc User Guide

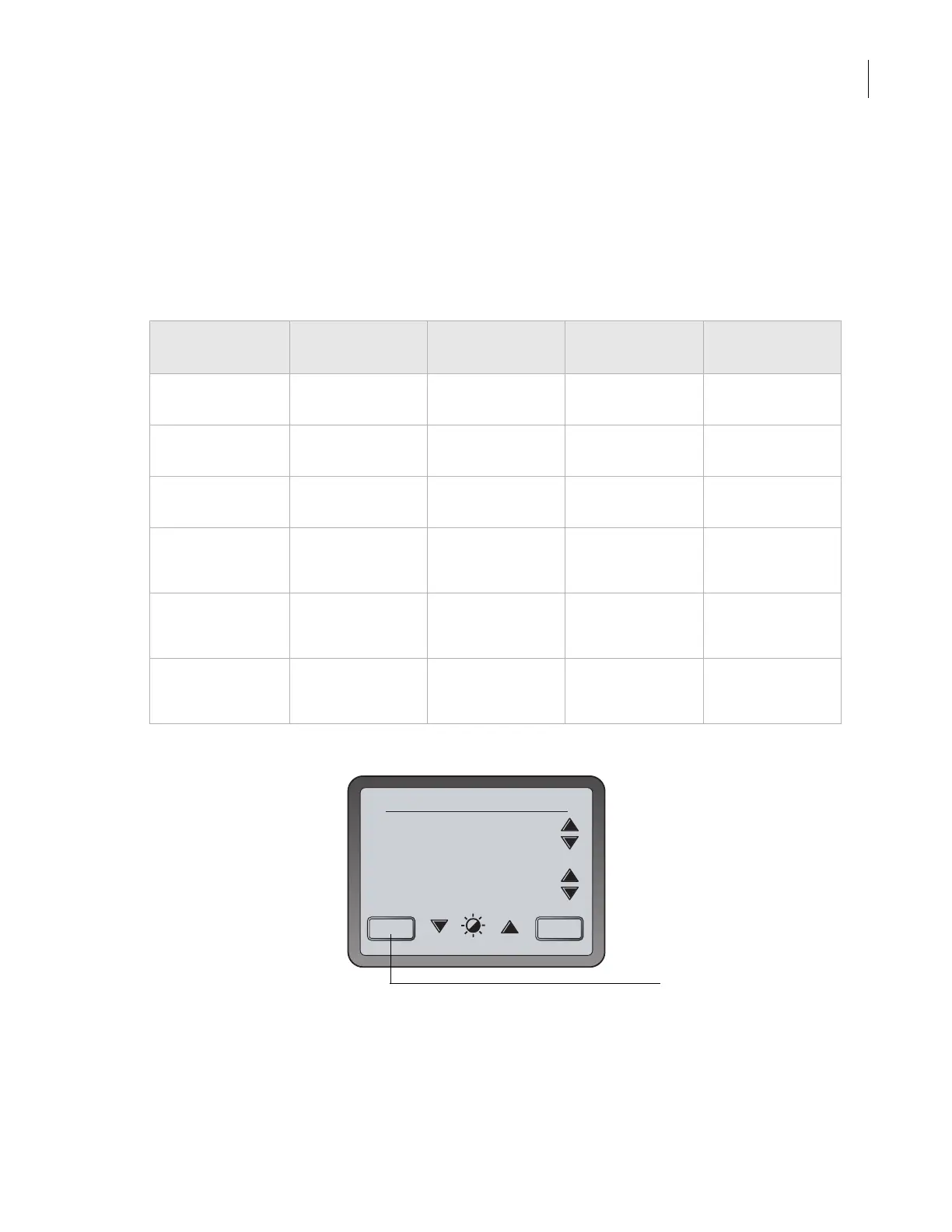

The seal time and temperature you specify depends on the type of

plate and the type of seal you are using. The following table shows

the settings you can use as a starting point. For the most up-to-date

starting point settings, see the PlateLoc Thermal Plate Sealer Seal

Selection Guide. You can locate the guide on the Velocity11 website

at www.velocity11.com.

Velocity11 recommends that you perform seal optimization tests to

determine the optimal seal time and temperature. For general

optimization guidelines, see “Optimizing seal quality” on page 77.

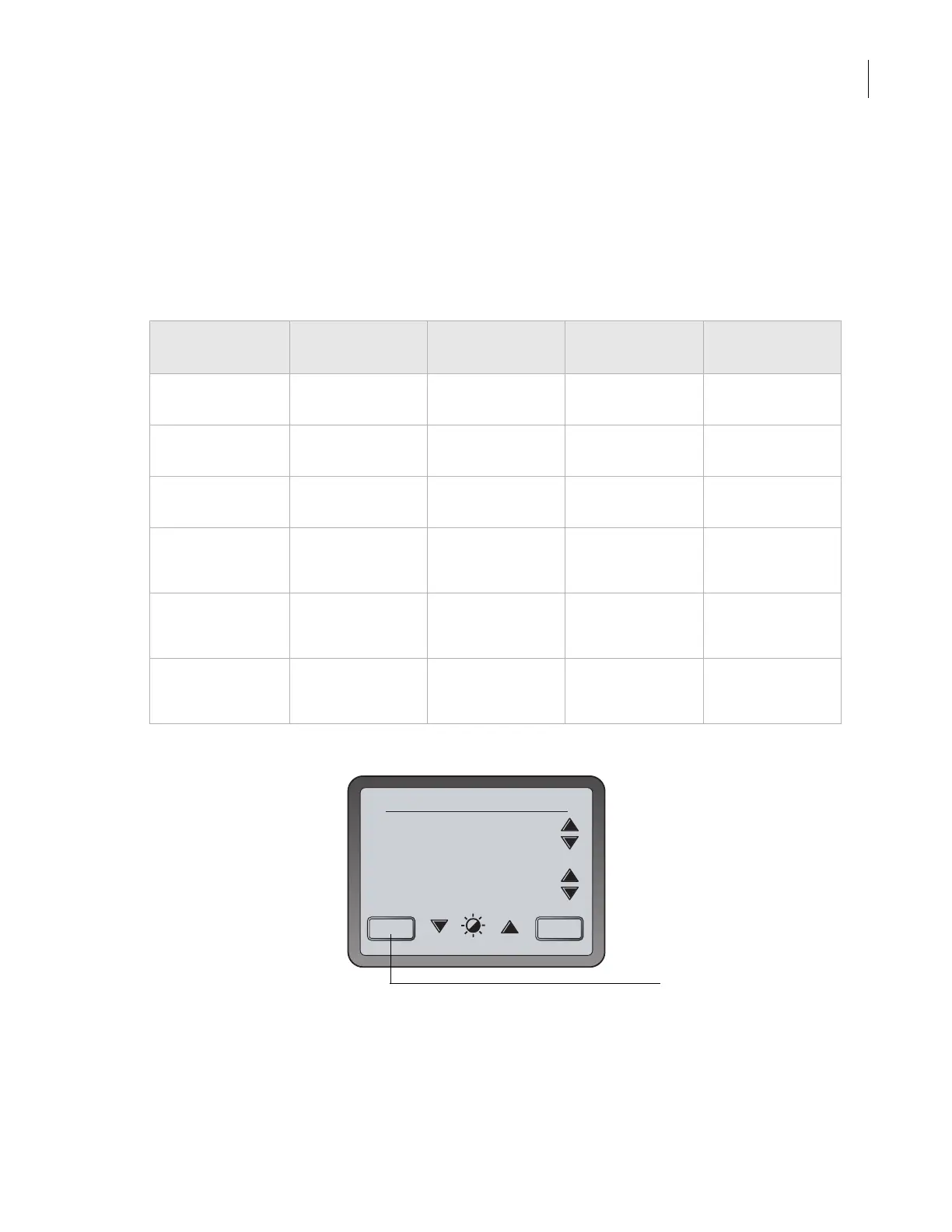

3. Gas-Purging PlateLocs only. In the

Set Parameters Menu, press Special.

Seal name

(part number)

Polycarbonate

plate

Polyethylene

plate

Polypropylene

plate

Polystyrene

plate

Clear Seal

(11452.001)

160

°C

1.5

s

160

°C

1.5

s

160

°C

1.5

s

160

°C

1.5

s

Clear Pierceable

Seal (14414.001)

130

°C

1.5

s

130

°C

1.5

s

130

°C

1.5

s

130

°C

1.5

s

Clear Peelable

Seal (16985.001)

——

130–150

°C

1.0–1.7

s

—

Clear Pierceable

Thin Seal

(17318.001)

——

130

°C

1.0–1.7

s

—

Peelable

Aluminum

(6643.001)

170

°C

1.2

s

170

°C

1.2

s

170

°C

1.2

s

170

°C

1.2

s

Pierceable

Aluminum

(6644.001)

170

°C

1.2

s

170

°C

1.2

s

170

°C

1.2

s

170

°C

1.2

s

Press Special.

00207

PlateLoc

screen menu 2

00207

PlateLoc

screen menu 2

Set Parameters Menu

Set Seal Time: 1.8s

Version 3.7.2 Cycle count: 63779

Set Seal Temp: 160°C

Special Done

Loading...

Loading...