Geometries with orientation support

144 Rockwell Automation Publication MOTION-UM002F-EN-P - February 2018

This table shows the current restrictions on the tool frame offsets for different

robot geometries supported by Logix Designer applications.

Geometry Type Coordinate

Definition

Tool Frame Offsets

X Y Z Rx Ry Rz

Delta

J1J2J6 Allowed Allowed Allowed Not Allowed Not Allowed Allowed

J1J2J3J6 Allowed Allowed Allowed Not Allowed Not Allowed Allowed

J1J2J3J4J5 Allowed Allowed Allowed Not Allowed Allowed Not Allowed

Tip:

The offset values must be set to 0

for restricted orientation offset inputs. The

MCTO/MCTPO instruction generates error #148 for invalid orientation offsets.

Establish a Tool frame

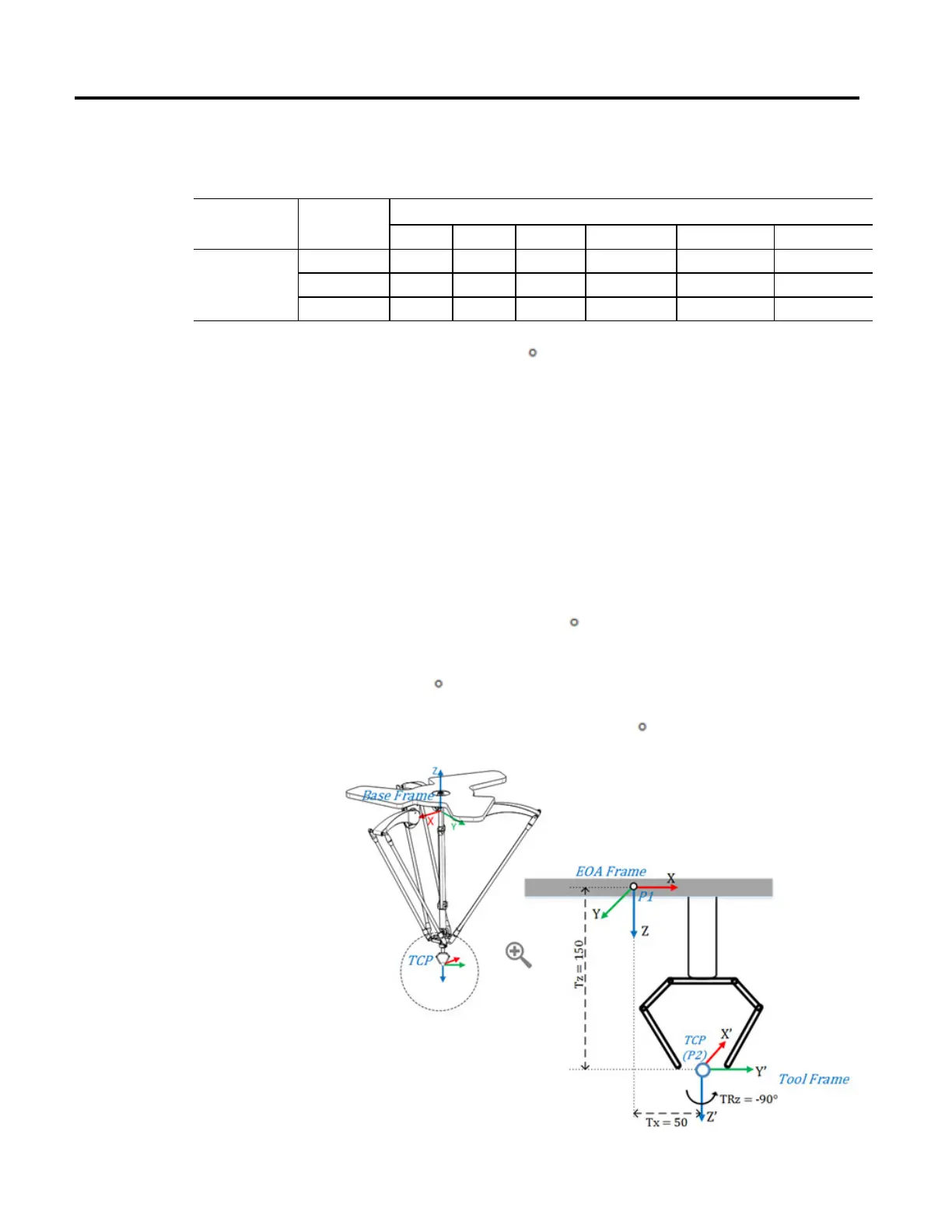

This diagram illustrates establishing a new Tool frame (X’Y’Z’) from the EOA

frame (XYZ) and change in the end position P of the robot with reference to a

new Tool Frame.

The simple gripper tool is attached at the end plate of 4 axis delta robot. TCP

point is measured from the EOA frame of the End plate. The Tool Frame X’Y’Z’

is located at 50 units on X axis, 150 units on Z axis, and rotated at -90 degree on Z

axis of the EOA frame XYZ. The Tool frame offset values are set as (X = 50, Y =

0, Z = 150, Rx = 0, Ry = 0, Rz = -90

)

Assume that the robot’s end position (P) is measured as P1 (X = 0, Y = 0, Z =

-800, Rx = 180

, Ry = 0, Rz = 0) from the base frame of the robot to the EOA

frame. With respect to a new tool frame, the end position (P) changes as P2 (X =

50, Y = 0, Z = -950, Rx = 180, Ry = 0, Rz = 90

).

Loading...

Loading...