Geometries with orientation support

Rockwell Automation Publication MOTION-UM002F-EN-P - February 2018 139

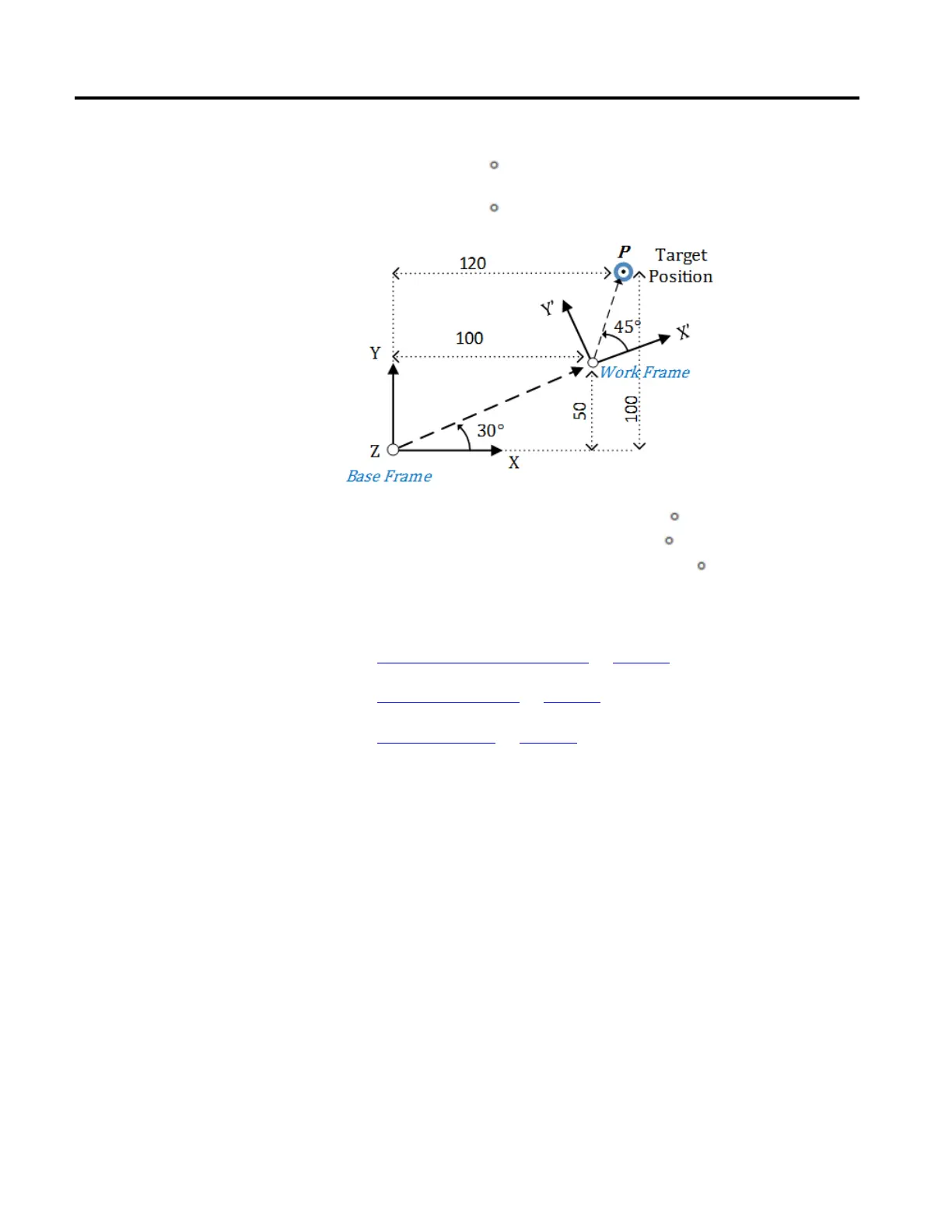

Assume that the target position (P) is measured as P1 (X = 120, Y = 100, Z = 0,

Rx = 0, Ry = 0, Rz = 75

) from the robot’s base frame. Now, with respect to a new

work frame, target position (P) will change as P2 (X = 42.321, Y = 33.301, Z = 0,

Rx = 0, Ry = 0, Rz = 45 ).

Position from the Base Frame (P1):

(X = 120, Y = 100, Z = 0, Rx = 0, Ry = 0, Rz = 75

)

Work Frame Offsets:

(X = 100, Y = 50, Z = 0, Rx = 0, Ry = 0, Rz = 30

)

Position from the Work Frame (P2):

(X = 42.321, Y = 33.301, Z = 0, Rx = 0, Ry = 0, Rz = 45

)

See also

Define coordinate system frames on page 134

Work frame examples on page 139

Tool frame offsets on page 142

These examples illustrate how to use work frames in different scenarios.

Multiple work frames with one robot base frame

Use work frames in scenarios where one robot works with multiple work frames or

multiple robots work with the same work frames. In this example, the target

positions and program remain the same, but the work frame’s offsets change based

on the different work frame positions.

Loading...

Loading...