Geometries with orientation support

Rockwell Automation Publication MOTION-UM002F-EN-P - February 2018 145

End position from the Base Frame (P1):

(X = 0, Y = 0, Z = -800, Rx = 180

, Ry = 0, Rz = 0)

Tool Frame Offsets:

(Tx =50, Ty = 0, Tz = 150, TRx = 0, TRy = 0, TRz = -90

)

End position with Tool Frame (P2):

(X = 50, Y = 0, Z = -950, Rx = 180

, Ry = 0, Rz = 90 )

Refer to the manufacturer CAD drawings or datasheet to find relevant Tool

Offset values for the tool.

See also

Define coordinate system frames on page 134

Tool frame example on page 145

Work frame examples on page 139

Work frame offsets on page 137

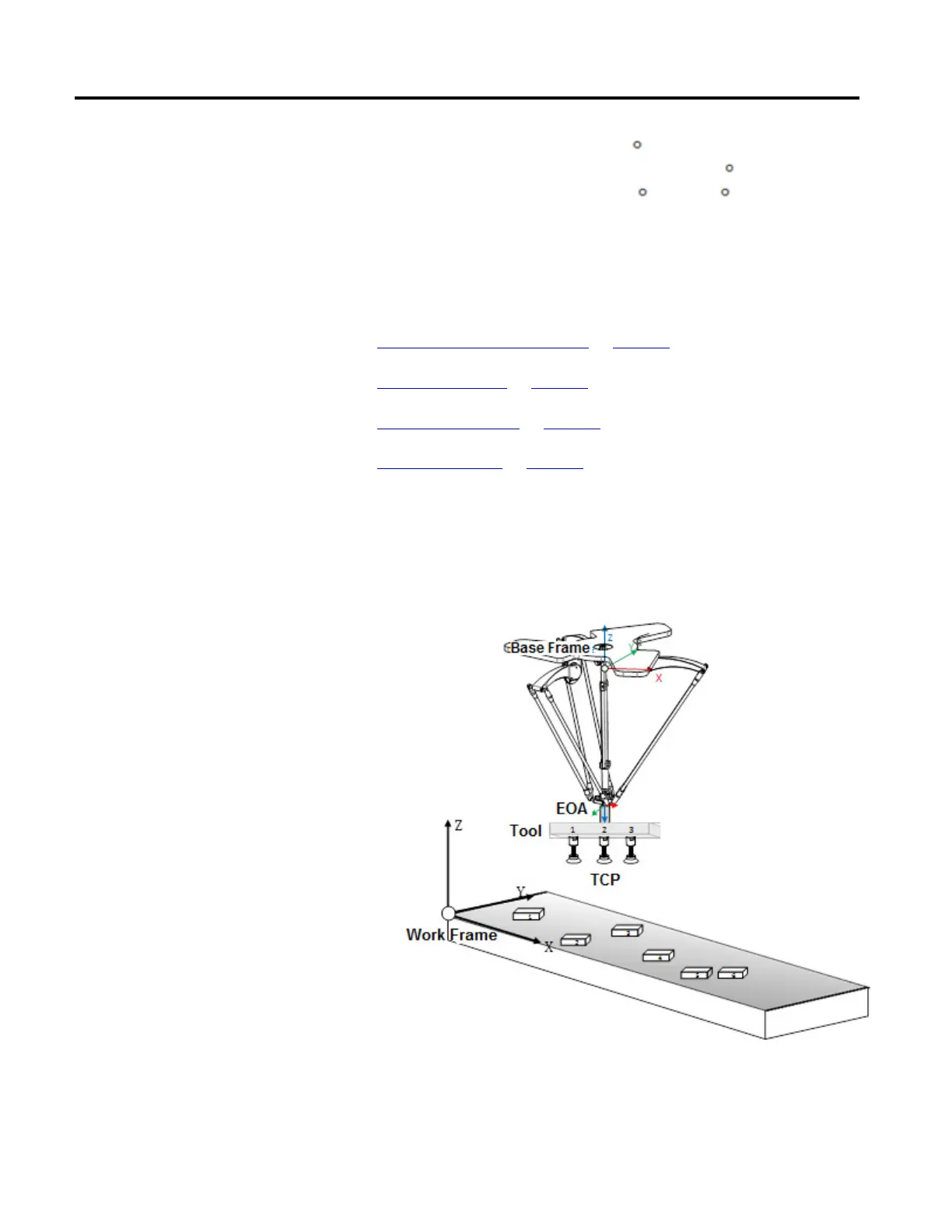

This illustration shows an example of using the Tool Frame in Pick & Place

applications. The custom tooling with three grippers (1, 2 and 3) is attached at the

end of 4-axis Delta robot. Each gripper is picking an object (1, 2, 3…6), placed at

different orientations from the moving conveyor and then putting them in to a

box with same orientations.

Each gripper is programmed as a separate tool and tool frames is associated with it.

All three TCP positions are measured using the tool offset values shown in the

Loading...

Loading...