Geometries with orientation support

146 Rockwell Automation Publication MOTION-UM002F-EN-P - February 2018

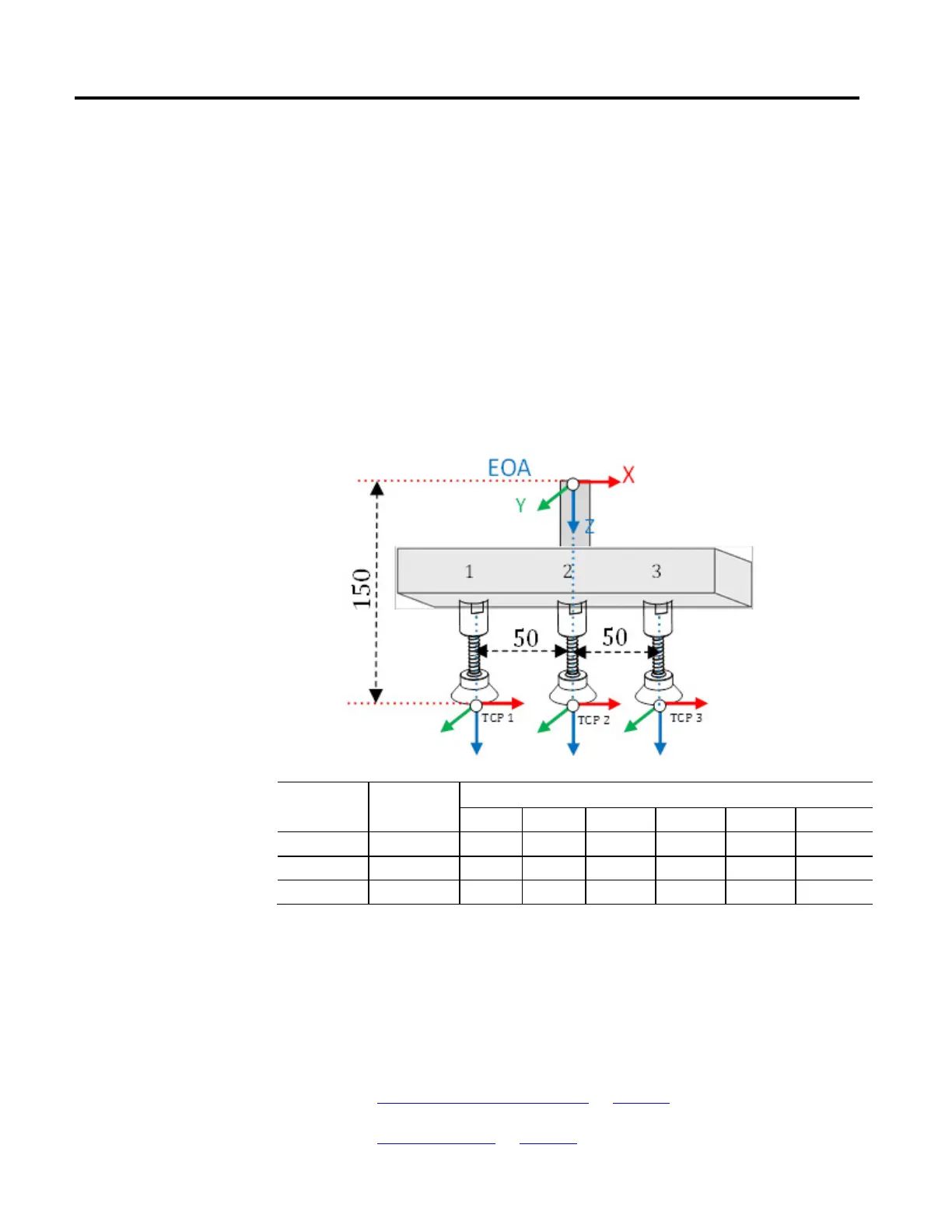

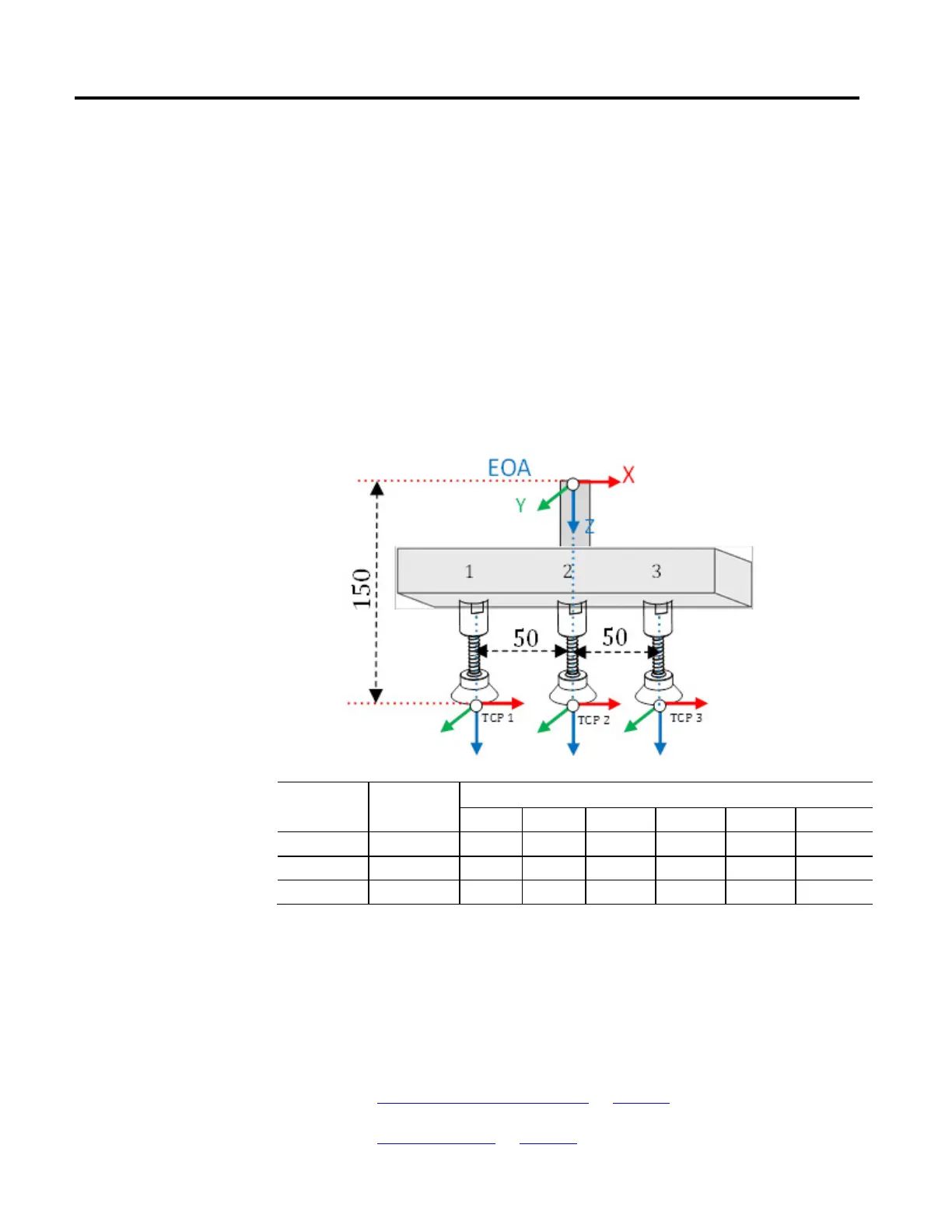

image. Individual tool frames are established through the tool frame offsets shown

in the table below.

In the application program, dynamically change the tool using the MCTO

instruction, while tracking the conveyor positions using the MAG or MAPC

instructions. Initiate the MCTO instruction with the first gripper’s tool frame

offset values. The robot picks the object using first gripper while the conveyor is

moving. When first move is completed, initiate new MCTO instruction with the

second gripper’s tool frame offsets. The robot picks another object using second

gripper.

Tip:

Refer to ToolChangeAllowedStatus status bit for dynamically changing the tool frame offsets. If this bit is

not set and new MCTO is initiated for tool change then new MCTO will generate #61 with extended error

#10. First the MCTO instruction bit (IP) is cleared when the second MCTO is initiated successfully.

Tool

Frames

Tool ID Tool Frame Offsets

X Y Z Rx Ry Rz

Tool 1 0 -50 0 150 0 0 0

Tool 2 1 0 0 150 0 0 0

Tool 3 2 50 0 150 0 0 0

Tip: To use this Kinematic sample projects, on the Help menu, click Vendor Sample Projects and then click the Motion

category.

The Rockwell Automation sample project's default location is:

c:\Users\Public\Public Documents\Studio 5000\Sample\ENU\v<current_release>\Rockwell Automation

See also

Define coordinate system frames on page 134

Tool frame offsets on page 142

Loading...

Loading...