Chapter 17 Motion control instructions

442 Rockwell Automation Publication 2080-RM001D-EN-E - February 2015

Axis error scenarios

In most cases, when a movement function block instruction issued to an axis

results in a function block error, the axis is also flagged as being in an Error state,

and the corresponding ErrorID element is set on the AXIS_REF data for the axis.

However, in the following situations, an axis error may not always be flagged, and

it is still possible for the user application to issue a successful movement function

block to the axis after the axis state changes.

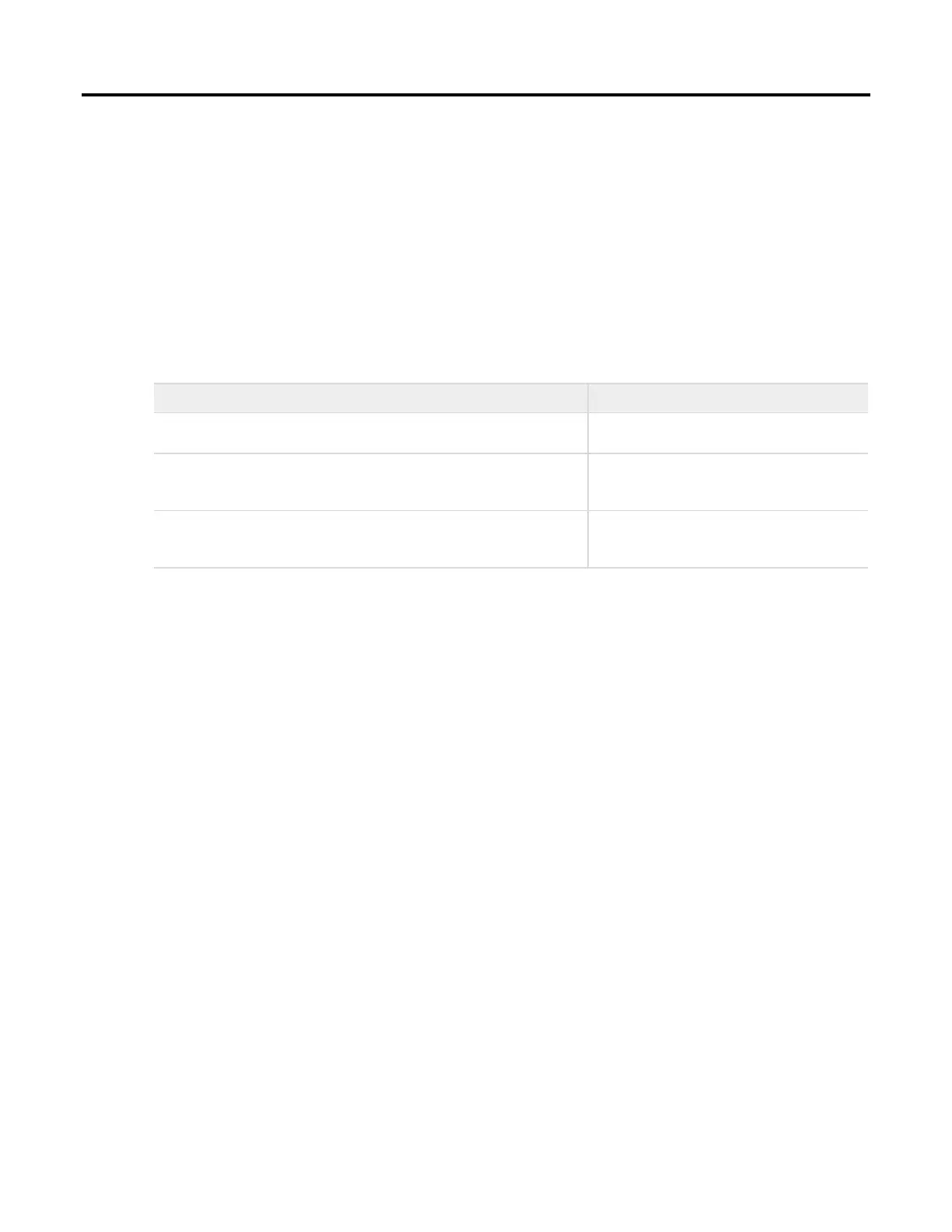

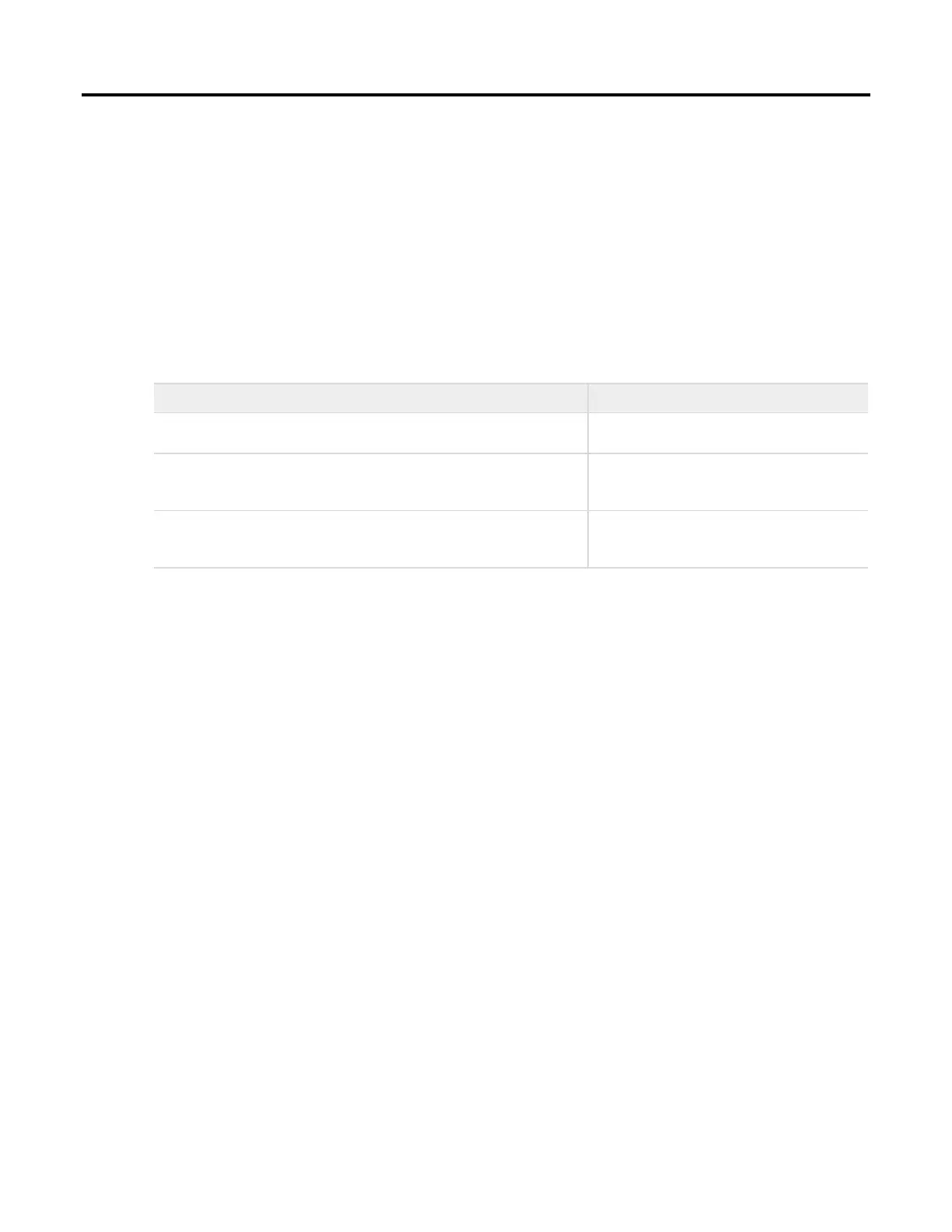

Scenario Example

A movement function block instructs an axis, but the axis is in a state in which the function block

cannot be executed properly.

The axis has no power, or the axis is in a Homing sequence, or

in an Error Stop state.

A movement function block instructs an axis, but the axis is still controlled by another movement

function block. The axis cannot allow the motion to be controlled by the new function block

without going to a full stop.

The new function block commands the axis to change motion

direction.

When one movement function block tries to control an axis, but the axis is still controlled by

another movement function block, and the newly-defined motion profile cannot be realized by the

controller.

User Application issues an S-Curve MC_MoveAbsolute function

block to an axis with too short a distance given when the axis is

moving.

Loading...

Loading...