102 Rockwell Automation Publication 6000-UM002E-EN-P - April 2018

Chapter 5 Preventative Maintenance and Component Replacement

1. Remove the mounting bolts (M6 x 20) from both sides of the Power

Module.

2. Disconnect the Three-phase Input Power Cables.

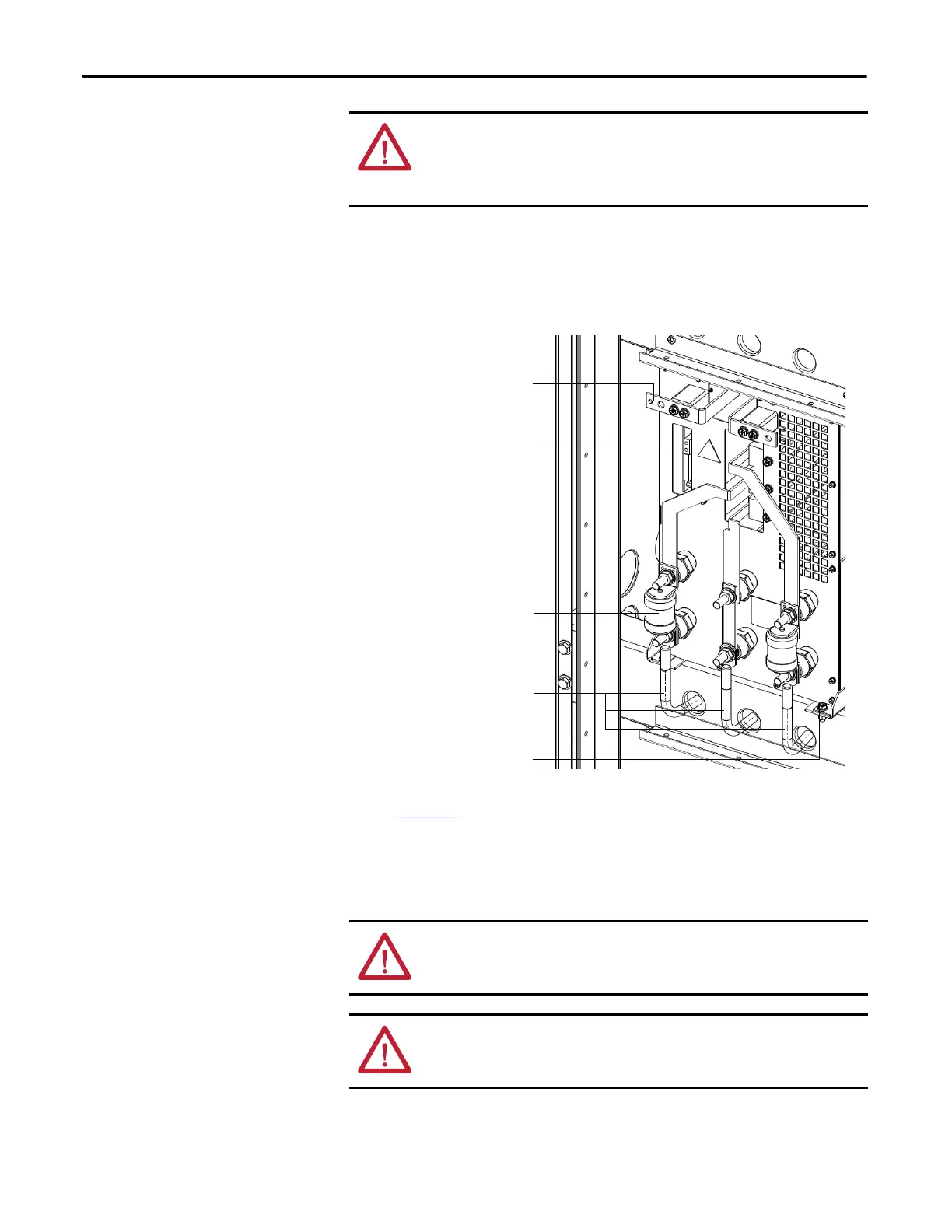

Figure 34 - Power Module Component Location

3. Remove the Output Copper Bars that connect adjacent Power Modules

(Figure 35

).

If the Power Module is at the end of a row, remove the VSB and Motor

cable instead of an output copper bus.

4. Disconnect the fiber optic cables.

ATTENTION: The high-voltage power source must be switched off before

replacing a Power Module. Wait for 20 minutes before opening the cabinet

doors. Verify that all circuits are voltage-free, using a hot stick or appropriate

high voltage-measuring device. Failure to do so may result in injury or death.

Fuse

Output copper bar (not shown)

connection location

Fiber optic cables connection point

Three-phase input cables

from isolation transformer

M6 x 20 mounting bolt

ATTENTION: When removing the fiber optic cables, be careful to prevent the

cables from straining or crimping as the resulting loss in light transmission will

impact performance.

ATTENTION: Minimum bend radius permitted for the fiber optic cables is 50

mm (2.0 in.). Any bends with a shorter inside radius can permanently damage

the fiber-optic cable.

Loading...

Loading...